High-performance light-weight air filtering paper and preparation method thereof

An air filter paper, high-performance technology, applied in the field of mineral fibers, can solve the problems of increasing production cost, increasing the resistance of air filter paper, increasing the raw material of air filter paper, etc., to achieve the effect of improving waterproof performance and improving air filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

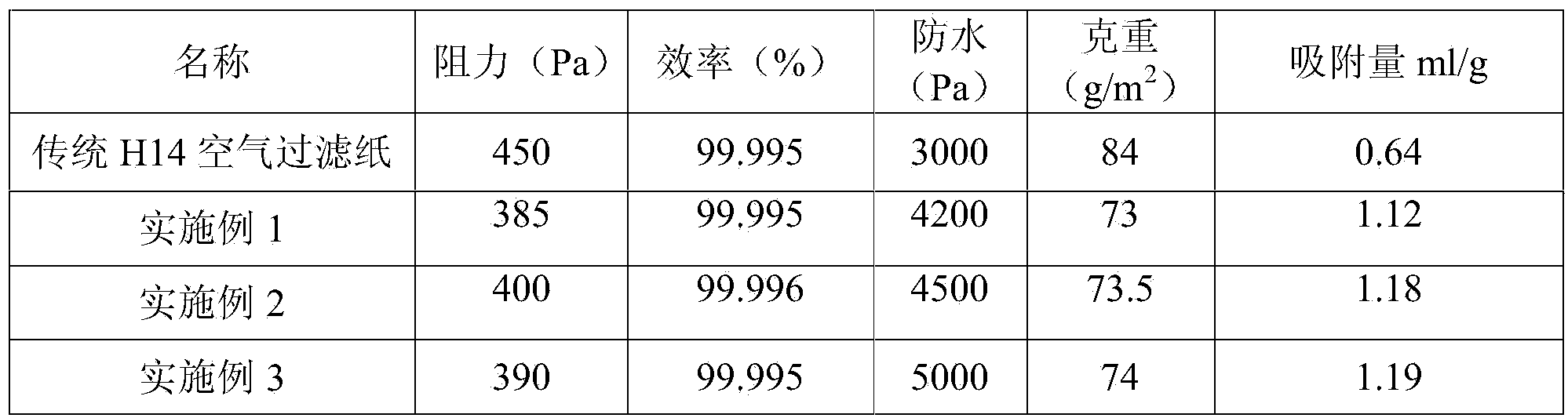

Examples

Embodiment 1

[0024] The method for preparing high performance low grammage air filter paper in this embodiment comprises the following steps:

[0025] 1) Dispersion pulping: first select the E-glass chopped strands with a diameter of 5-6um and the E-glass wool with a diameter of 0.3-0.8um in a ratio of 1:4, then mix the selected raw materials and Add water and sulfuric acid and stir evenly to make a pulp suspension; adjust the addition of water and sulfuric acid so that the mass concentration of the obtained pulp suspension is 0.15%, and the pH value is 4.5;

[0026] 2) Adjustment of pH in the pre-making tank: first remove the slag from the pulp suspension in step 1) and move to the storage tank, then transfer the pulp suspension to the for-making tank, then add clear water to the paper-making tank to adjust the pH of the pulp suspension to 5 and Store for 0.3h; control the amount of water added so that the mass concentration of the pulp suspension is 0.2%;

[0027] 3) Headbox pH adjustme...

Embodiment 2

[0032] The method for preparing high performance low grammage air filter paper in this embodiment comprises the following steps:

[0033] 1) Dispersion pulping: first select the E-glass chopped strands with a diameter of 5-6um and the E-glass wool with a diameter of 0.3-0.8um at a ratio of 1:9, then mix the selected raw materials and Add water and sulfuric acid and stir evenly to make a pulp suspension; adjust the addition of water and sulfuric acid so that the mass concentration of the obtained pulp suspension is 1.2%, and the pH value is 4;

[0034] 2) Adjustment of pH in the pre-making tank: first remove the slag from the pulp suspension in step 1) and move to the storage tank, then transfer the pulp suspension to the for-making tank, then add clear water to the paper-making tank to adjust the pH of the pulp suspension to 4 and Store for 0.8h; control the amount of water added so that the mass concentration of the pulp suspension is 2.5%;

[0035] 3) pH adjustment of the h...

Embodiment 3

[0040] This embodiment prepares the method for high-performance low weight air filter paper, comprises the following steps:

[0041] 1) Dispersion pulping: first select the E-glass chopped strands with a diameter of 5-6um and the E-glass wool with a diameter of 0.3-0.8um in a ratio of 1:7, then mix the selected raw materials and Add water and sulfuric acid and stir evenly to make a pulp suspension; adjust the addition of water and sulfuric acid so that the mass concentration of the obtained pulp suspension is 0.2%, and the pH value is 4.8;

[0042] 2) Adjustment of pH in the pre-making tank: first remove the slag from the pulp suspension in step 1) and move to the storage tank, then transfer the pulp suspension to the for-making tank, then add clear water to the paper-making tank to adjust the pH of the pulp suspension to 5 and Store for 0.5h; control the amount of water added so that the mass concentration of the pulp suspension is 0.23%;

[0043] 3) Headbox pH adjustment: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com