Efficient disinfection-ozone destruction integrated air filter element for vehicle and production equipment of efficient disinfection-ozone destruction integrated air filter element

An air filter element and production equipment technology, applied in the field of high-efficiency disinfection-ozone-destruction integrated air filter element for vehicles and its production equipment, can solve the problems of general filter element filtration effect, affecting filtration effect, difficult to deal with harmful odor and peculiar smell, etc. The effect of eliminating harmful odors and substances and improving the air filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

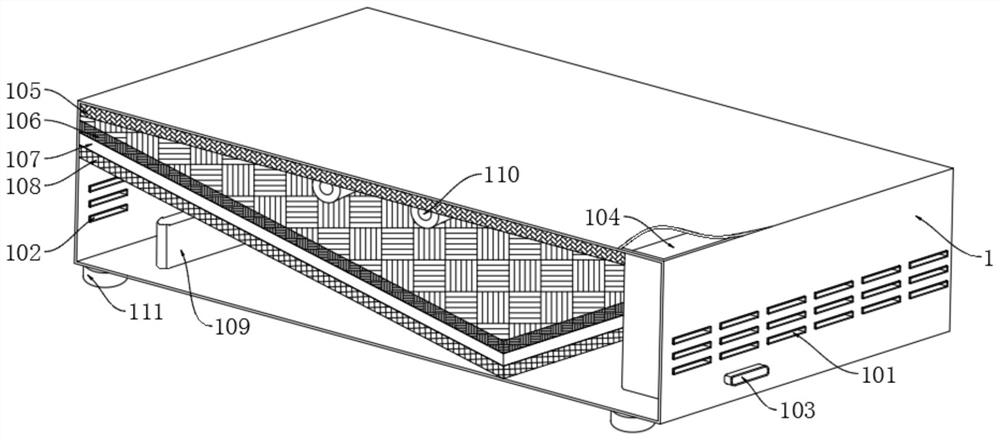

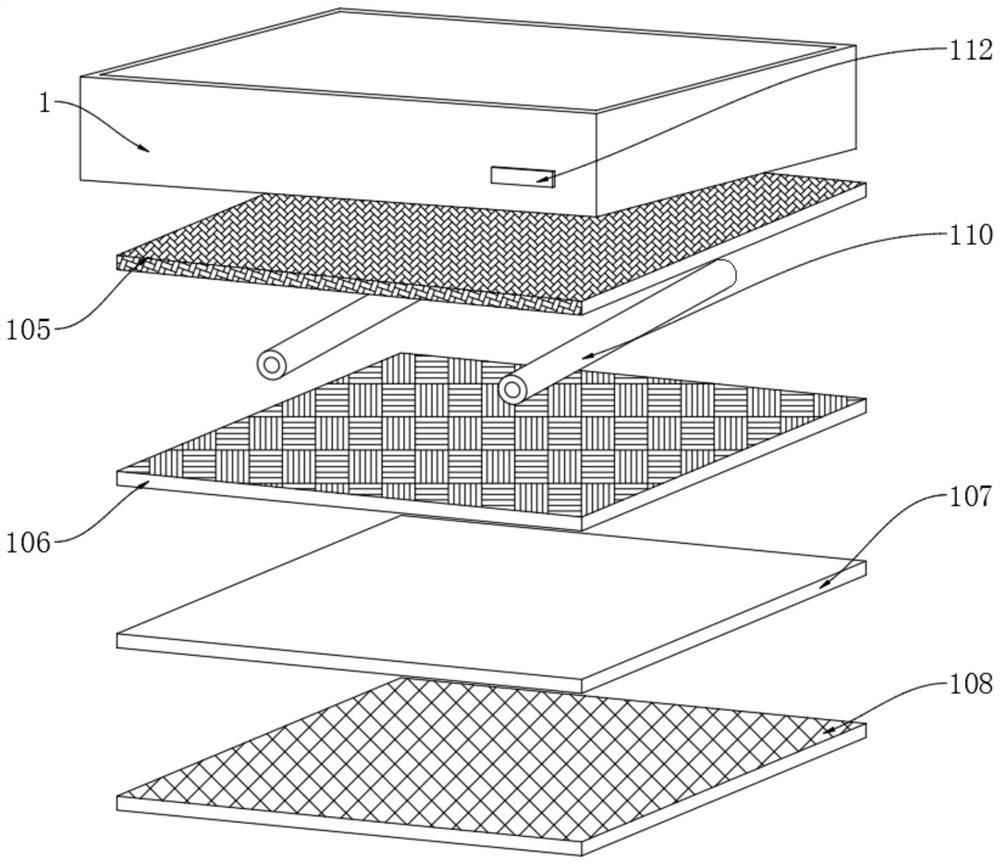

[0047] like Figure 1 to Figure 2 As shown, the high-efficiency disinfection-ozone-destroying integrated air filter element for vehicles in this embodiment includes an outer frame 1, one side of the outer frame 1 is evenly provided with an air inlet 101, and the other side of the outer frame 1 is evenly opened with an outlet Air port 102, a fan 104 is arranged inside the outer frame 1 on one side of the air inlet 101, a primary filter cotton 105 is installed on the top inner wall of the outer frame 1, and an ultraviolet lamp 110 is fixedly installed on the surface of the primary filter cotton 105, A photocatalytic mesh 106 is installed obliquely inside the outer frame 1, and a HEPA filter 107 and an ozone destruction filter 108 are arranged below the photocatalytic mesh 106 in sequence, and the air outlet 102 is installed inside the outer frame 1. There are aromatherapy boxes 109.

[0048] Specifically, a magnetic power supply seat 112 is installed on the front end surface of...

Embodiment 2

[0051] On the basis of Example 1:

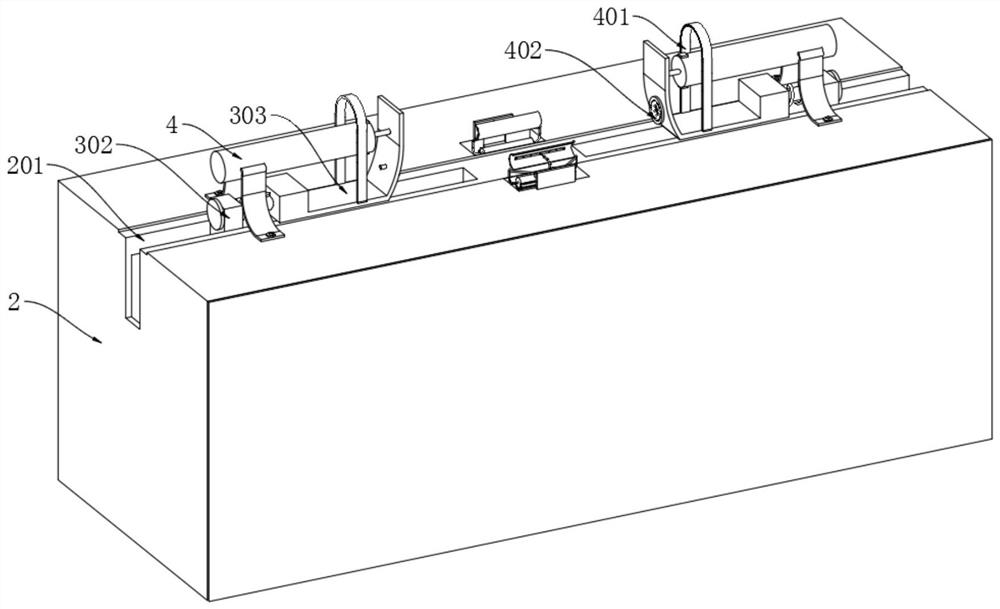

[0052] like Figure 3 to Figure 5 Shown, the production equipment of the high-efficiency disinfection-ozone-destruction integrated air filter element for vehicles in the present embodiment, further, the chute 201 opened on the top surface of the machine 2 and the machine 2, the inside of the machine 2 is fixedly installed with the motor 3 , and the output shaft of the motor 3 is fixedly connected with a transmission guide rod 301 , a slider 302 is mounted on the surface of the transmission guide rod 301 , and the top of the slider 302 extends out of the chute 201 , and the extension of the slider 302 is installed There is a rubber plate 303, a gear 304 is rotatably installed on one side surface of the slider 302, and the gear 304 is limitedly installed on the surface of the transmission guide rod 301, and the top of the machine table 2 is movably installed with a processing mechanism through a slot , a traction mechanism is installed at the...

Embodiment 3

[0055] On the basis of embodiment 2:

[0056] like Figure 5 , Figure 7 and Figure 11 As shown, the production equipment of the high-efficiency disinfection-ozone-destruction integrated air filter element for vehicles in this embodiment, further, the traction mechanism includes a drawing pipe 4, a blowing pipe 401 and an execution part, and a suction pipe is fixedly installed at the top edge of the machine 2. Pull the tube 4, and the movable part of the pulling tube 4 is connected with the rubber plate 303, the surface of the rubber plate 303 is fixedly installed with the blowing pipe 401, and the blowing pipe 401 is connected with the surface of the pulling tube 4 through the one-way valve hose, and the execution part Mounted on the surface of the rubber plate 303 .

[0057] At work: as Figure 5 , Figure 7 and Figure 11 As shown, on the basis of the movement of the rubber plate 303, because the movable part of the pulling tube 4 is fixedly connected with the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com