Processing technique for manufacturing golden tobacco shreds

A processing technology, golden color technology, applied in the field of processing technology for making golden yellow shredded tobacco, can solve the problems of reduced tobacco leaf quality, browning of shredded leaf color, high heating temperature, etc., and achieve reduced aroma loss, reduced color browning, and The effect of reducing the return air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

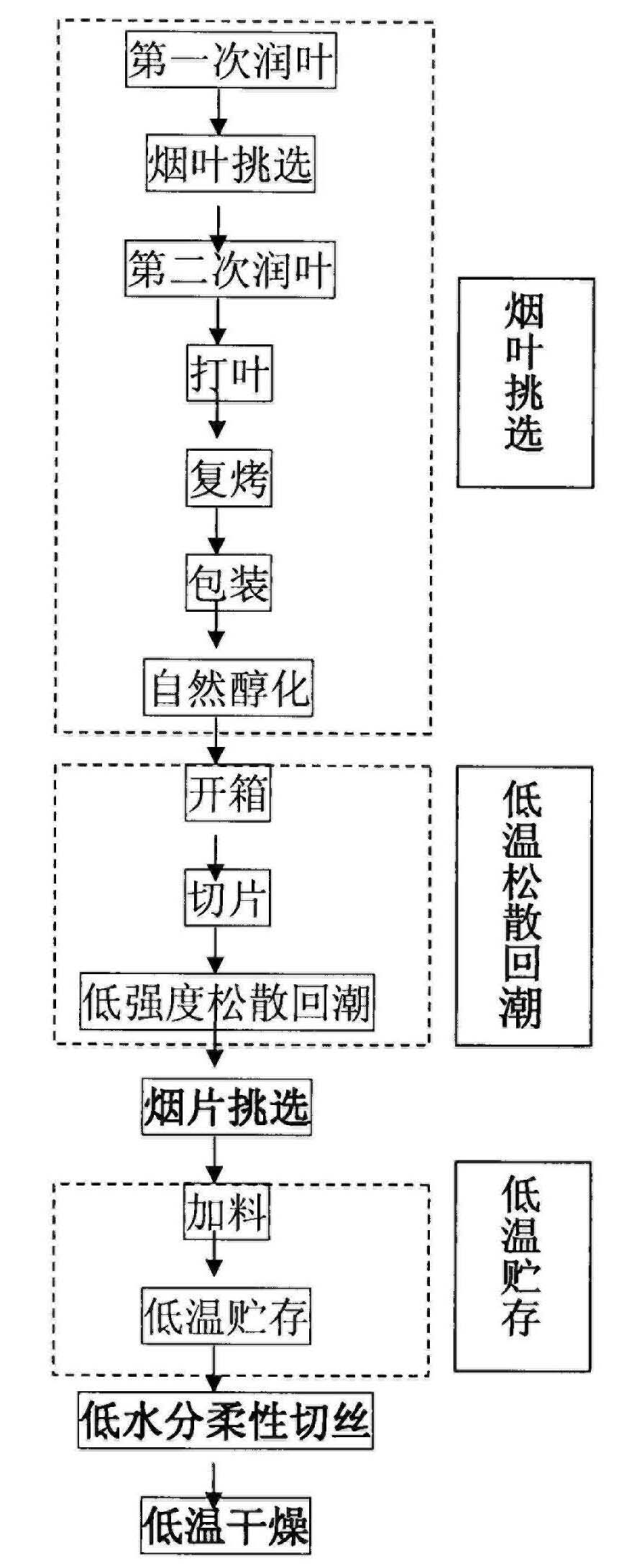

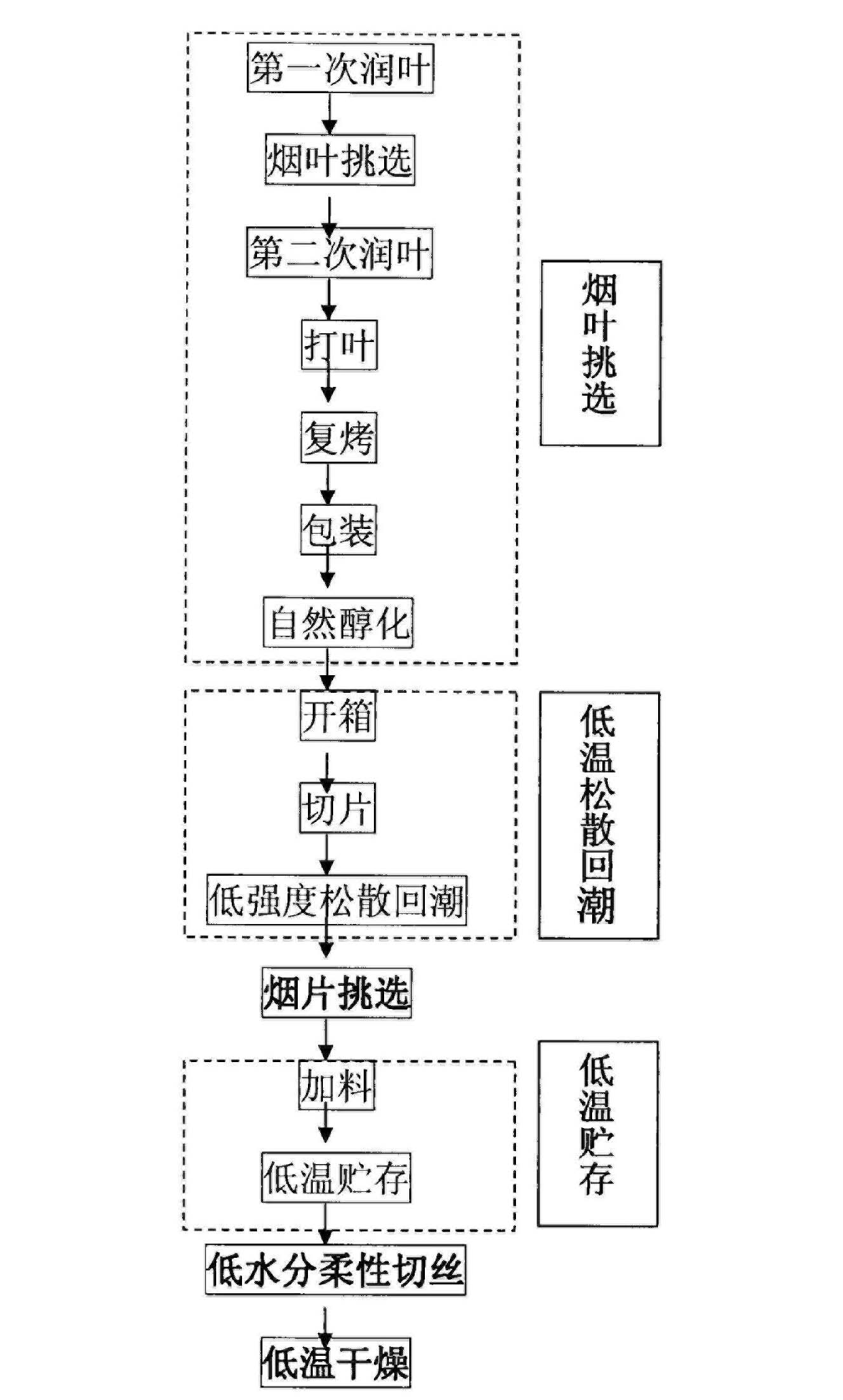

[0023] The tobacco leaf raw materials of a certain type of tobacco leaf group formula are sent to the leaf selection table for manual selection after the first moistening in the threshing and redrying plant, and the golden yellow or nearly golden tobacco leaves are selected according to the existing threshing and redrying The roasting process involves moistening the leaves for the second time, threshing the leaves, and air separation. The smoke sheets separated by the wind are mixed and then re-roasted and packaged. After 2 years of natural alcoholization, the silk production is carried out. The alcoholized smoked sheets are unpacked and sliced, and sent to low-strength loosening and dampening equipment for loosening and dampening treatment. The return air temperature of the loose moisture return is 45±1°C, the outlet moisture content is 16%±1%, and the treatment time is 3 minutes. The loosely rehydrated smoke sheets are sent to the photoelectric sorting machine to select agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com