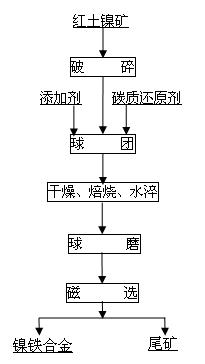

Method for producing ferronickel from lateritic nickel ores

A technology of lateritic nickel ore and ferronickel, which is applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve problems such as difficulty in mastering, low comprehensive recovery rate, complex technology, etc. Low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]The treated lateritic nickel ore contains 1.56% nickel, 22% iron, and 3% magnesium. After grinding, 99% is less than 5mm. The mass ratio of ingredients is ore: additive: carbonaceous reducing agent = 100:30:20, sulfuric acid The mass ratio of magnesium, magnesium fluoride, and magnesium oxide is 4:3:3; the diameter of pellets is 10~15mm; the drying temperature is 100°C; the drying time is 1h; the roasting temperature is 1150°C; the roasting time is 1.5h; The intermediate product is obtained after quenching, and then finely ground by a ball mill. The ore particle size is 100% less than 74μm, and the mass concentration of the pulp is 20%. Magnetic separation under a magnetic field of 80mT yields a nickel-iron alloy containing 12.34% nickel and 72.56% iron, nickel The recovery rate is 88%.

Embodiment 2

[0035] The treated nickel laterite ore contains 1.67% nickel, 16.1% iron, and 10.5% magnesium. After grinding, 100% is less than 5mm. The mass ratio of ingredients: ore: additive: carbonaceous reducing agent = 100: 5:10; sulfuric acid in additive The mass ratio of magnesium, magnesium fluoride, and magnesium oxide is 4:3:0; the diameter of the ball is about 20mm; the drying temperature is 150°C; the drying time is 1h; the roasting temperature is 1000°C; the roasting time is 2.5h; the roasted material is quenched by water Finally, the intermediate product is obtained, and after being finely ground by a ball mill, the particle size of the ore is 100% less than 74 μm, the mass concentration of the pulp is 25%, and the nickel-iron alloy containing 10.34% of nickel and 68.56% of iron is obtained by magnetic separation under a magnetic field of 200mT. The recovery rate is 91%.

Embodiment 3

[0037] The treated nickel laterite ore contains 1.89% nickel, 26.1% iron, and 2% magnesium. After grinding, 98% is less than 5mm. The mass ratio of ingredients: ore: additive: carbonaceous reducing agent = 100:20:30, sulfuric acid in additive The mass ratio of magnesium, magnesium fluoride, and magnesium oxide is 4:3:3; the diameter of the ball is about 30mm, the drying temperature is 200°C, the drying time is 1h, the roasting temperature is 900°C, and the roasting time is 5h. The roasted material is quenched by water The intermediate product is obtained, and after being finely ground by a ball mill, the particle size of the ore is 100% less than 74 μm, the mass concentration of the pulp is 15%, and an alloy containing 10.34% nickel and 79.56% iron is obtained by magnetic separation under a magnetic field of 150mT, and the recovery rate of nickel is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com