Antibacterial glass fiber air filtering paper and production method thereof

An air filter paper, glass fiber technology, applied in the direction of filter paper, filtration separation, separation method, etc., can solve the problems of poor performance, high price of nano-silver, affecting the service life of filter paper, etc., to achieve stable physical and chemical properties, reduce survival and effect of reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

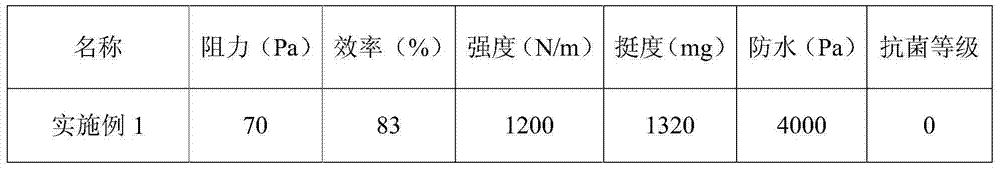

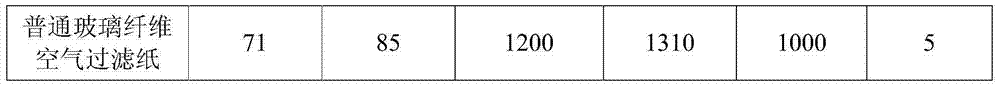

Examples

Embodiment 1

[0031] The preparation method of effective antibacterial glass fiber air filter paper in the present embodiment may further comprise the steps:

[0032] 1) Pulping: Take 50 parts of non-alkali glass fiber cotton with a diameter of 3.2mm and 10 parts of non-alkali glass fiber cotton with a diameter of 0.9um, add the glass fiber cotton to the beater, then add clear water and sulfuric acid to make Slurry PH=3.8, mass concentration is 2.7%, then beating and dispersing, the beating time is about 33 minutes to obtain pulp suspension;

[0033] 2) Forming: diluting step 1) the suspension to a mass concentration of 0.3% and performing slag removal; then transporting the slurry to an inclined wire former for wet forming to obtain wet paper;

[0034] 3) sizing: sizing the wet paper obtained in step 2), the sizing material is an acrylic emulsion, a waterproof emulsion and an antibacterial agent;

[0035] 4) Dehydration: suck the wet paper of step 3) sizing with a vacuum suction tank, so ...

Embodiment 2

[0039] The preparation method of effective antibacterial glass fiber air filter paper in the present embodiment may further comprise the steps:

[0040] 1) Pulping: Take 40 parts of non-alkali glass fiber cotton with a diameter of 3.5mm and 10 parts of non-alkali glass fiber cotton with a diameter of 0.8um, add the glass fiber cotton to the beater, then add clear water and sulfuric acid to make Slurry PH=3.5, mass concentration is 2.5%, then beating and dispersing, the beating time is about 30 minutes to obtain pulp suspension;

[0041] 2) Forming: diluting step 1) the suspension to a mass concentration of 0.4% and performing slag removal; then transporting the slurry to an inclined wire former for wet forming to obtain wet paper;

[0042] 3) sizing: sizing the wet paper obtained in step 2), the sizing material is an acrylic emulsion, a waterproof emulsion and an antibacterial agent;

[0043] 4) Dehydration: use a vacuum suction tank to suck the wet paper of step 3) sizing, s...

Embodiment 3

[0047] The preparation method of effective antibacterial glass fiber air filter paper in the present embodiment may further comprise the steps:

[0048] 1) Pulping: Take 60 parts of non-alkali glass fiber cotton with a diameter of 3.0 and 10 parts of non-alkali glass fiber cotton with a diameter of 1.0um, add the glass fiber cotton to the beater, and then add water and sulfuric acid to make the pulp The material pH=4.0, the mass concentration is 3.0%, and then beating and dispersing is performed, and the beating time is about 35 minutes to obtain a pulp suspension;

[0049] 2) Forming: diluting step 1) the suspension to a mass concentration of 0.2% and performing slag removal; then transporting the slurry to an inclined wire former for wet forming to obtain wet paper;

[0050] 3) sizing: sizing the wet paper obtained in step 2), the sizing material is an acrylic emulsion, a waterproof emulsion and an antibacterial agent;

[0051] 4) Dehydration: suck the wet paper of step 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com