High-basicity and high-tenacity submerged-arc welding flux for oceaneering and preparation method of high-basicity and high-tenacity submerged-arc welding flux

A submerged arc flux and marine engineering technology, applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problems of high drying temperature, poor impact toughness, etc., achieve lower drying temperature, low moisture absorption, Effect of improving slag removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

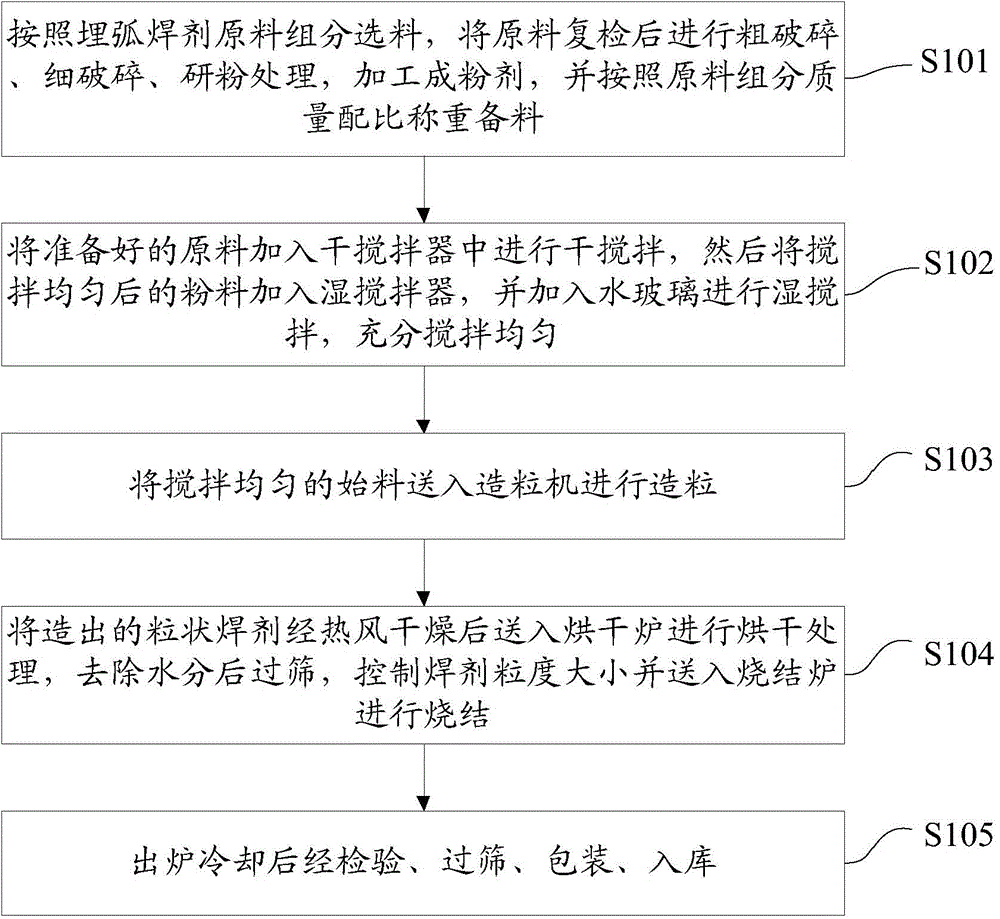

[0039] The embodiment of the present invention also provides a preparation method of high-alkalinity and high-toughness submerged arc welding flux for marine engineering, such as figure 1 shown, including the following steps:

[0040] Step S101, selecting materials according to the raw material components of the submerged arc welding flux, re-inspecting the raw materials, performing coarse crushing, fine crushing, and powder processing, processing them into powder, and weighing and preparing materials according to the mass ratio of raw material components;

[0041] Step S102, adding the prepared raw materials into a dry blender for dry blending, then adding the uniformly stirred powder into a wet blender, adding water glass for wet blending, and stirring thoroughly;

[0042] Step S103, sending the uniformly stirred starting material into a granulator for granulation;

[0043]Step S104, drying the produced granular flux with hot air and then sending it to a drying furnace for ...

Embodiment 1

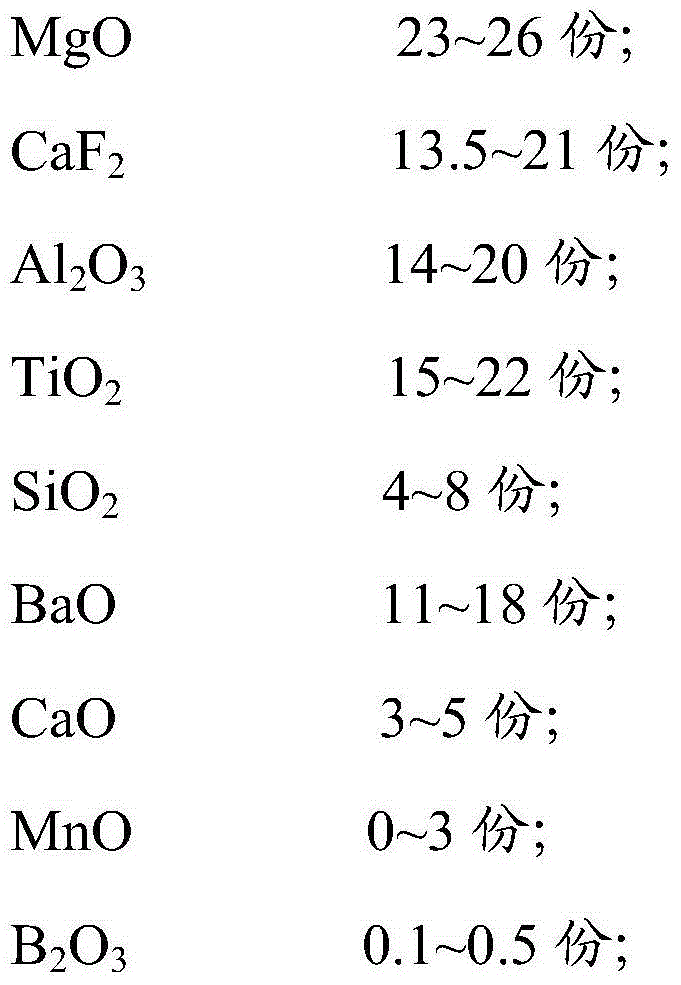

[0051] Flux composition and mass percentage:

[0052] MgO: 25 parts; CaF 2 : 20 copies; Al 2 o 3 : 15 parts; TiO 2 : 16 parts; SiO 2 : 8 parts; BaO: 11 parts; CaO: 3 parts; MnO: 1 part; 2 o 3 : 0.5 part, the balance is unavoidable impurities.

[0053] Alkalinity of flux: 2.5;

[0054] Preparation method: After re-inspecting the required raw materials, carry out the processes of coarse crushing, fine crushing, and powder grinding, and process them into powders with different standard particle sizes. After sieving, carry out proportioning and weighing according to the formula, then put it into a dry blender for dry blending, put the evenly stirred powder into a wet blender, add water glass with 20% of the powder mass for wet blending, and stir well , the stirred raw material is sent to the granulator for granulation, and the granulated flux produced is sent to the drying furnace after being dried by hot air, and is dried at a temperature of 150-200°C, and sieved after re...

Embodiment 2

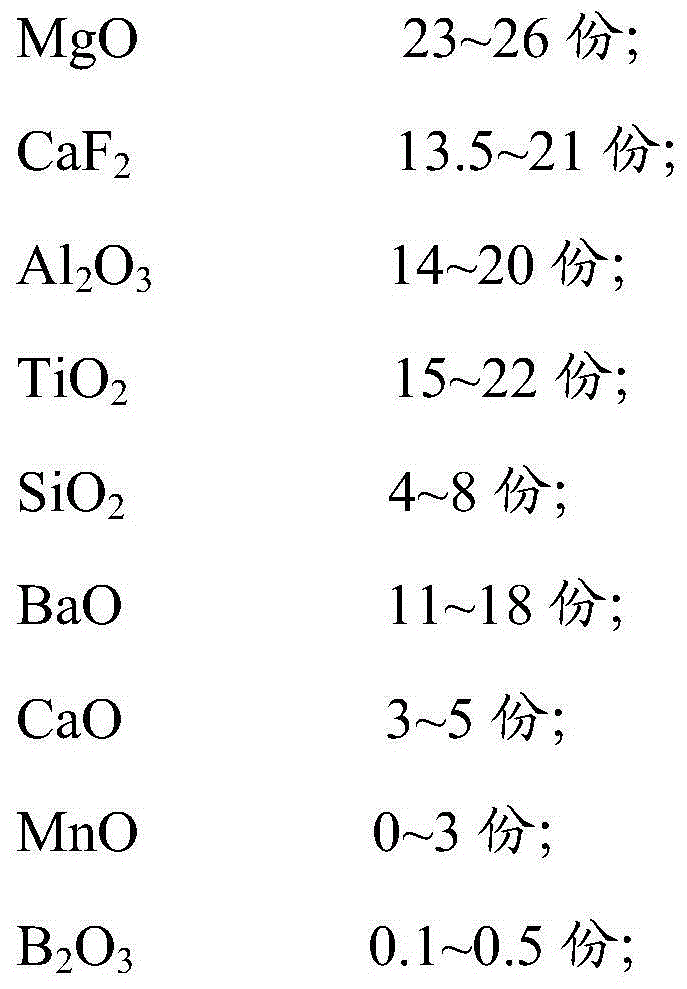

[0057] Flux composition and mass percentage:

[0058] MgO: 26 parts; CaF 2 : 20 copies; Al 2 o 3 : 20 parts; TiO 2 : 15 parts; SiO 2 : 4 parts; BaO: 11 parts; CaO: 3.4 parts; MnO: 0; B 2 o 3 : 0.1 part, the balance is unavoidable impurities.

[0059] Alkalinity of flux: 2.8;

[0060] Preparation method: After re-inspecting the required raw materials, carry out the processes of coarse crushing, fine crushing, and powder grinding, and process them into powders with different standard particle sizes. After sieving, carry out proportioning and weighing according to the formula, then put it into a dry blender for dry blending, put the evenly stirred powder into a wet blender, add water glass with 20% of the powder mass for wet blending, and stir well , the stirred raw material is sent to the granulator for granulation, and the granulated flux produced is sent to the drying furnace after being dried by hot air, and is dried at a temperature of 150-200°C, and sieved after rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com