Steel-concrete folding plate combined beam

A reinforced concrete slab and concrete technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of complex construction procedures and structures, slow construction speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

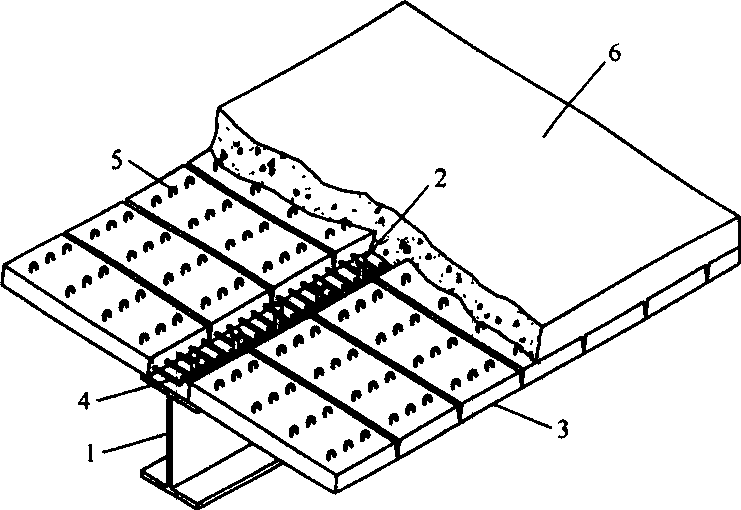

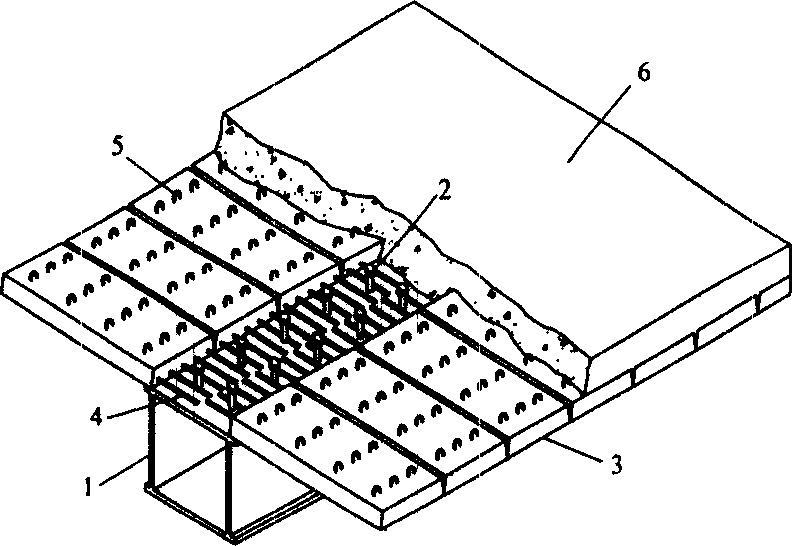

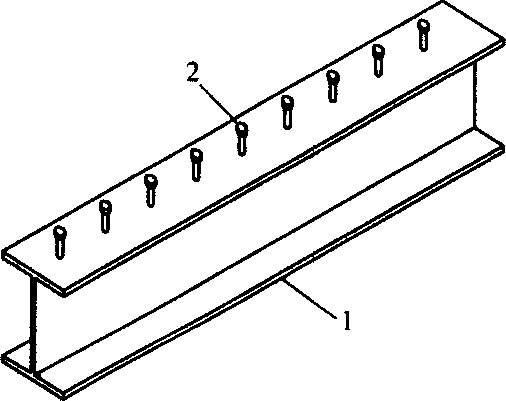

[0015] The invention provides a steel-concrete laminated slab composite beam. The laminated slab composite beam is welded on the steel beam 1 with shear connectors (bolts or channel steel) 2, and the solid reinforced concrete or hollow reinforced concrete prefabricated slab 3 is horizontally placed on the steel beam 1 (I-shaped steel beam or box-shaped steel beam) ) on the upper flange of the slab, which not only bears the construction load, but also bears the vertical load as a part of the floor; the beard tendons 4 protruding from the end of the prefabricated slab cross each other, and at least 1 / 3 of them are welded to each other to play the role of longitudinal shear resistance. function; the top surface of the prefabricated slab 3 is roughened, and the shear structural reinforcement 5 can also be arranged in the prefabricated slab to increase the connection performance with the post-cast concrete 6; Seat negative moment reinforcement. The prefabricated slab and cast-in-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com