Method for monitoring corrosion cracks of reinforced concrete and sensor

A reinforced concrete and sensor technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to interpret the whole process of material cracking and cracking, and achieve good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

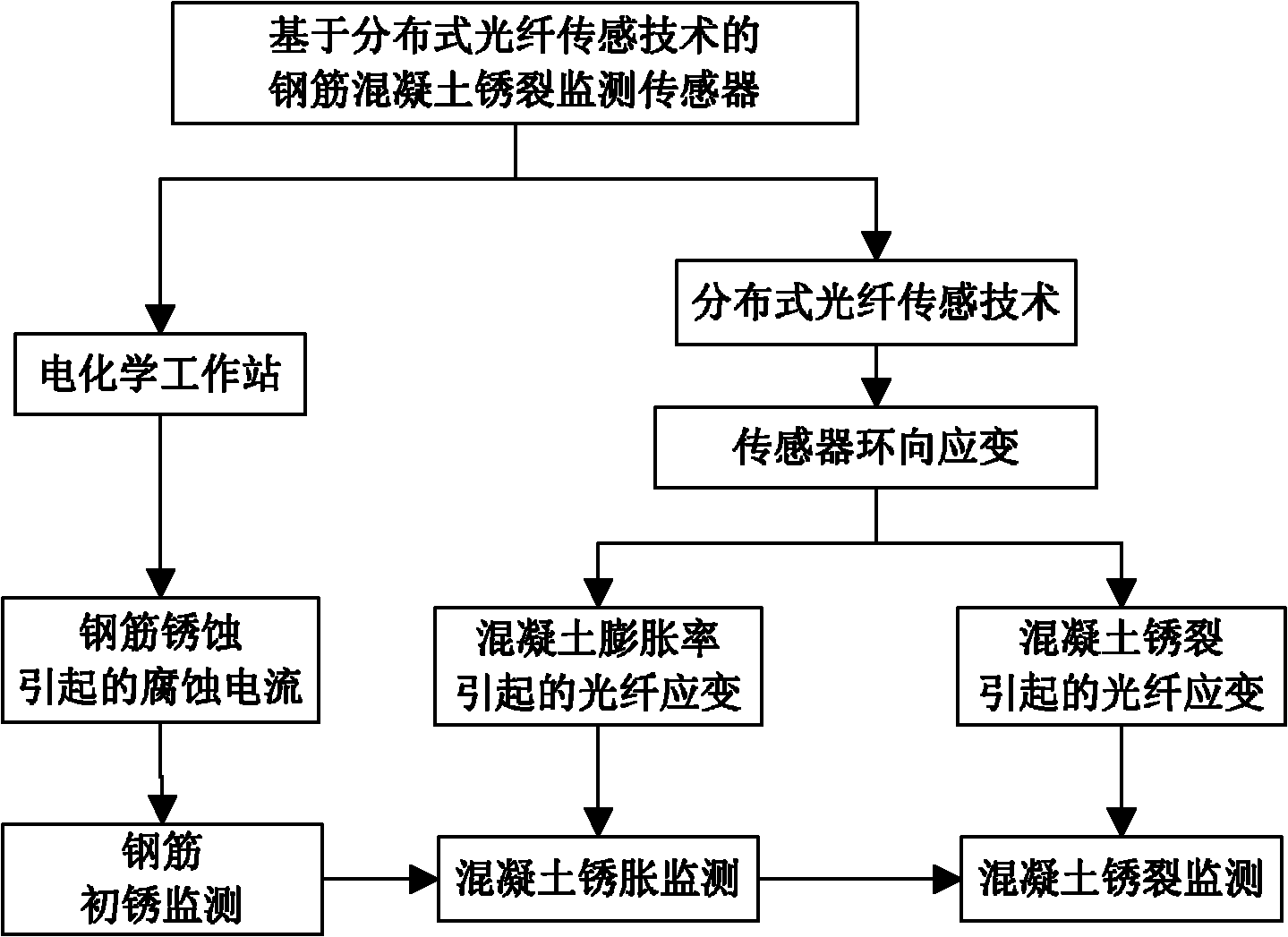

[0039] To further illustrate the technical solution of the present invention, the following will be described in detail in conjunction with the accompanying drawings:

[0040] 1. Sensor production

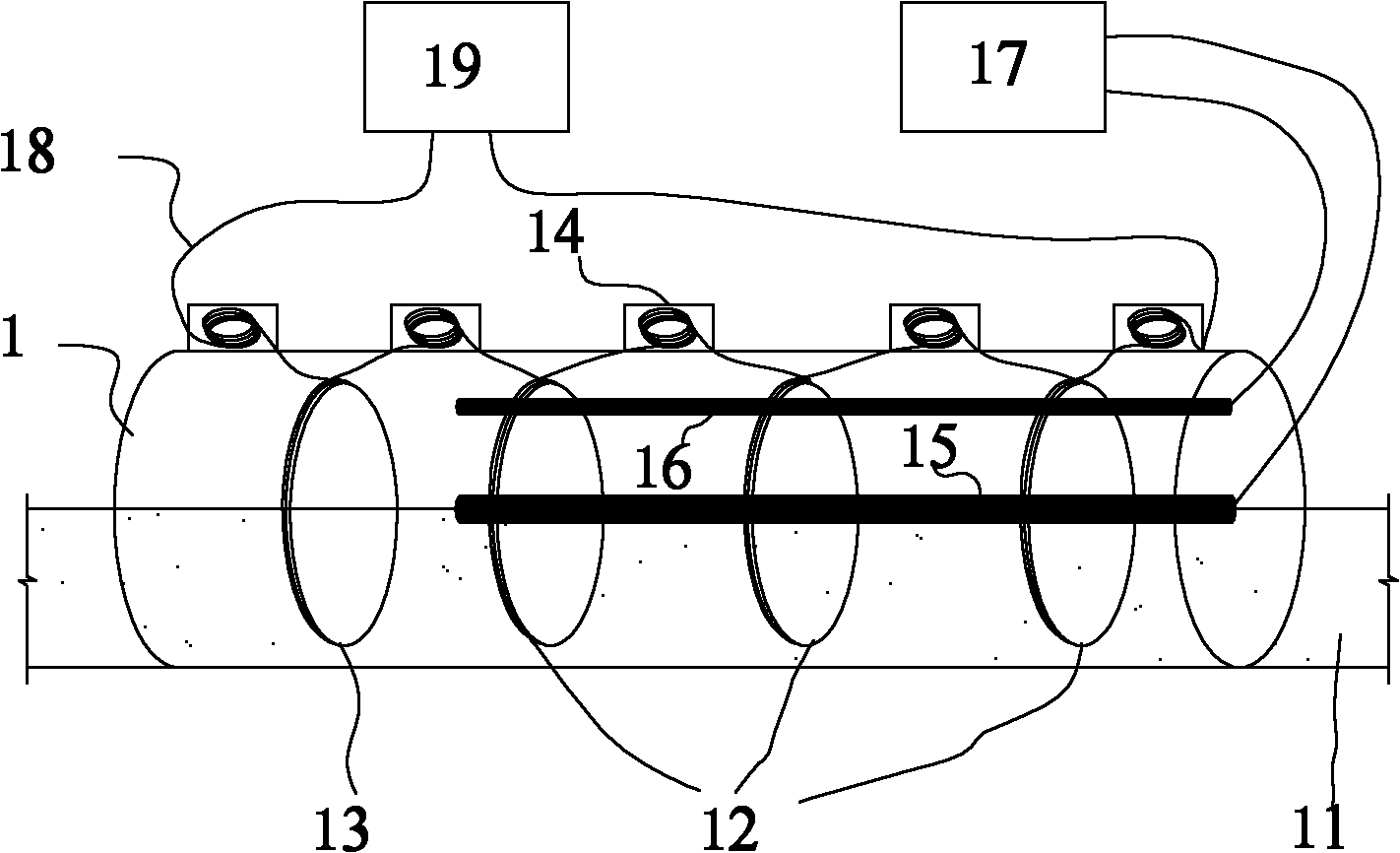

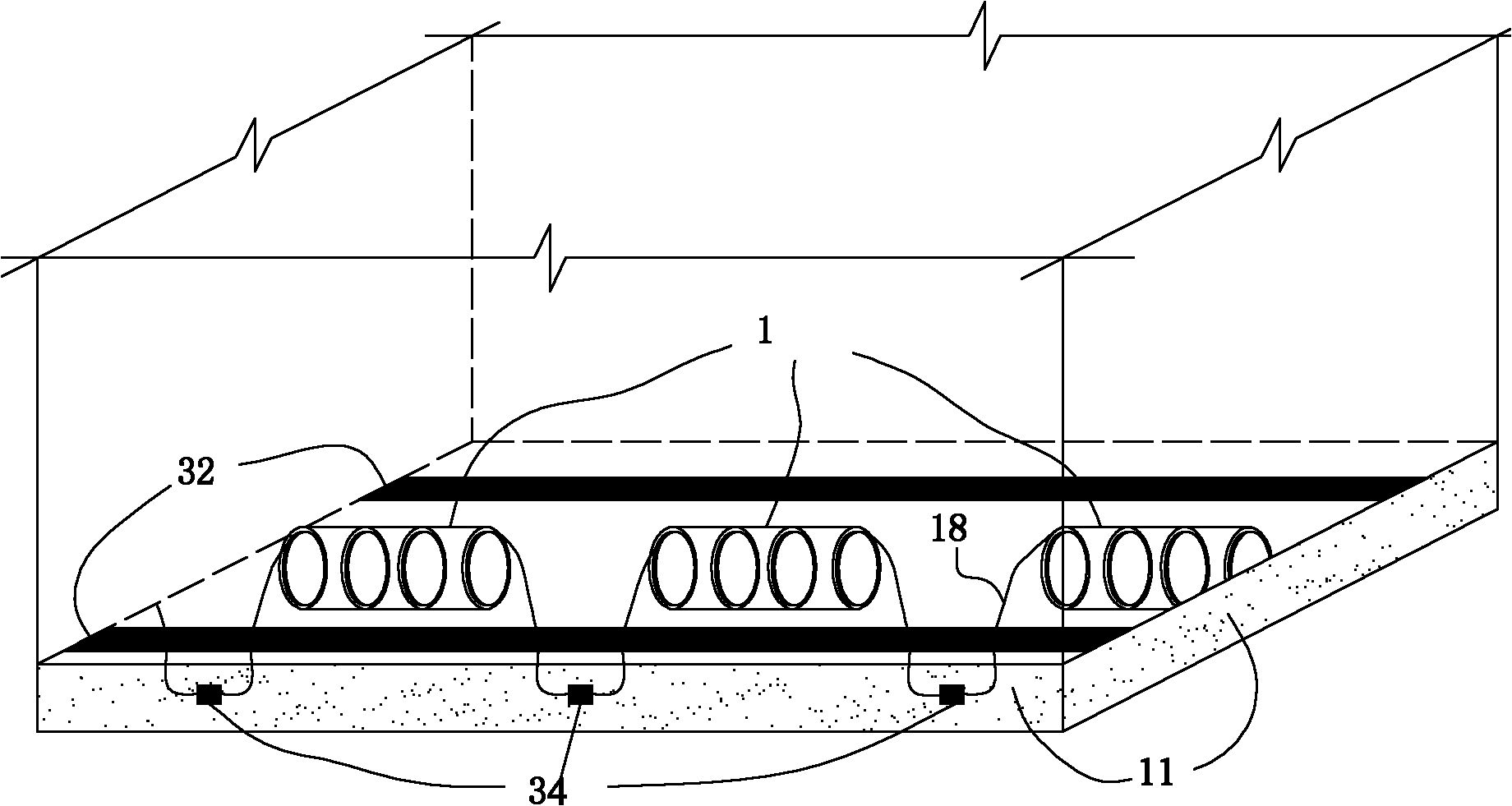

[0041] In the process of structural concrete construction, the sensor of this embodiment is directly embedded in the concrete by binding with structural steel bars. Its structural features are as follows: figure 1 shown.

[0042] The sensor is a cylindrical concrete specimen 1 with a specific length, the radius of which is consistent with the thickness of the concrete protective layer 11 of the structure to be measured, and the simulated steel bars 15 and concrete materials thereof are consistent with the structure to be measured. The length of simulated steel bars 15 and stainless steel 16 inside the sensor is slightly shorter than the length of the sensor. Both ends are sealed with epoxy resin and then connected to wires, connected to the electrochemical workstation 17 to judge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com