Method and an apparatus for twisting and tightening a wire

a technology of twisting and tightening wires, applied in the direction of wrapping/bundling articles, packaging, constructions, etc., can solve the problems of difficult to achieve satisfactory binding force, excessive use of binding wires, and high cost of binding reinforcement bars in concrete constructions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] A preferred embodiment of the invention will now be described in details with reference to the drawing in which:

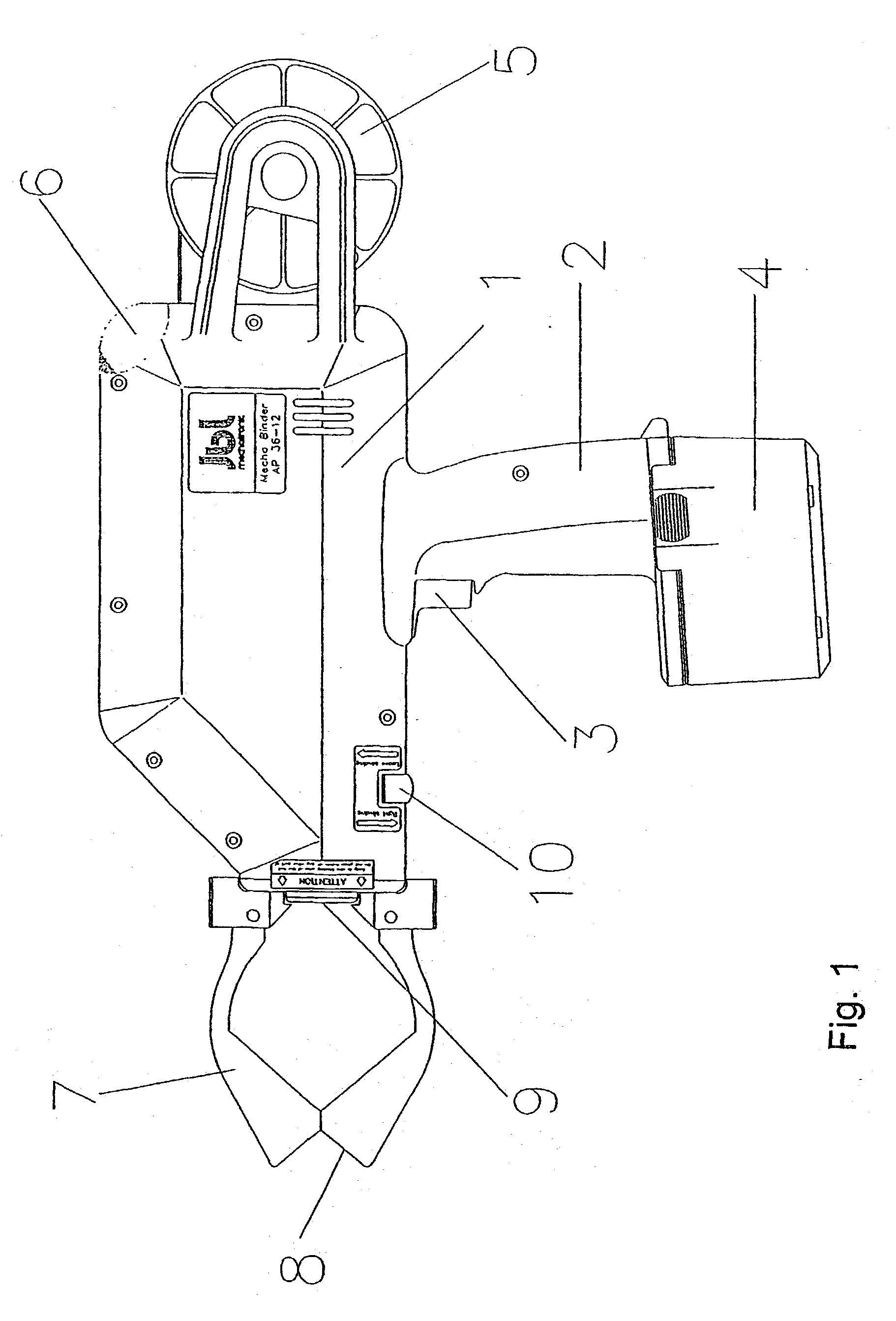

[0072] FIG. 1 shows a binder according to the present invention, seen from the side,

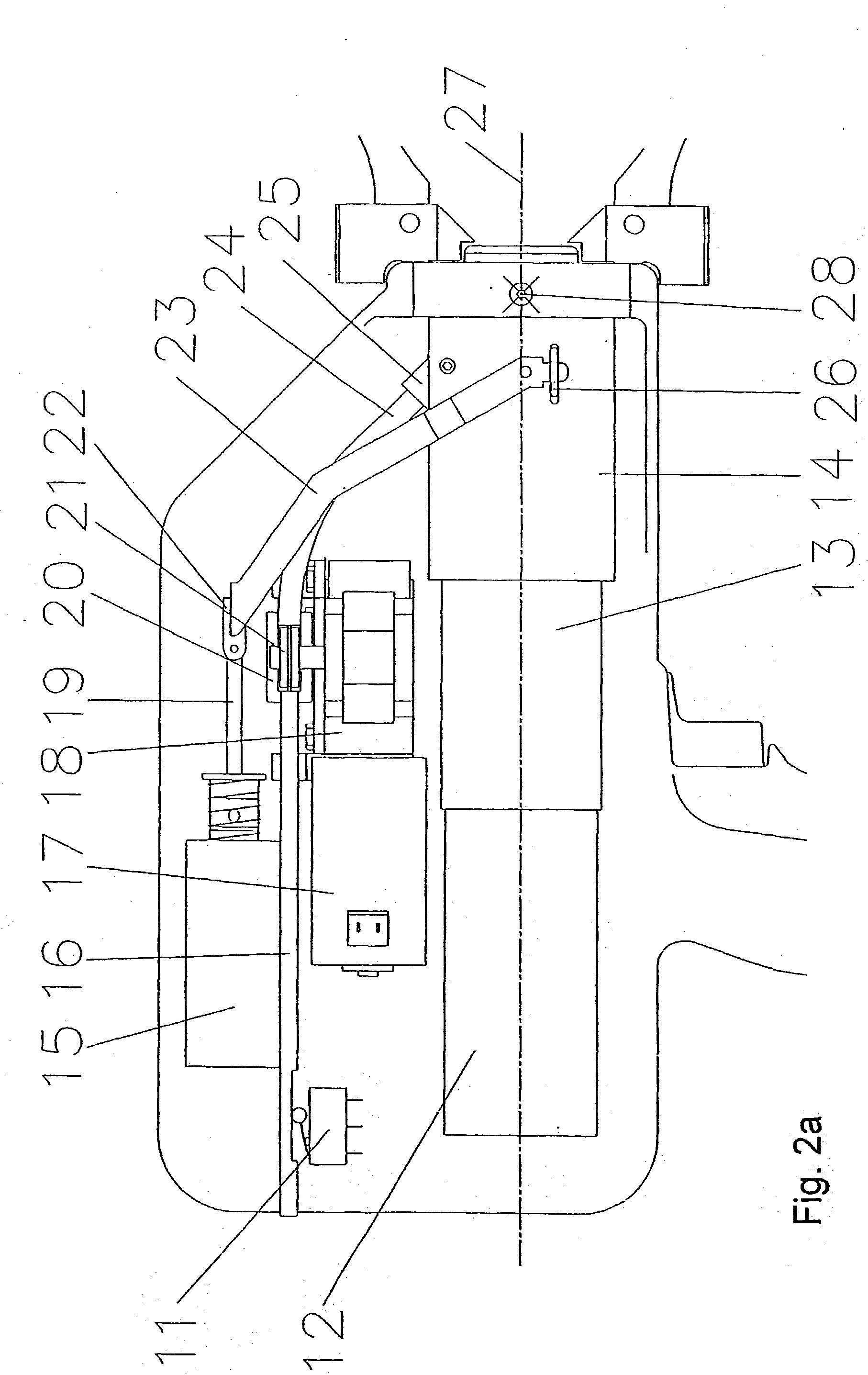

[0073] FIG. 2a shows the binder of FIG. 1 with the outer casing removed,

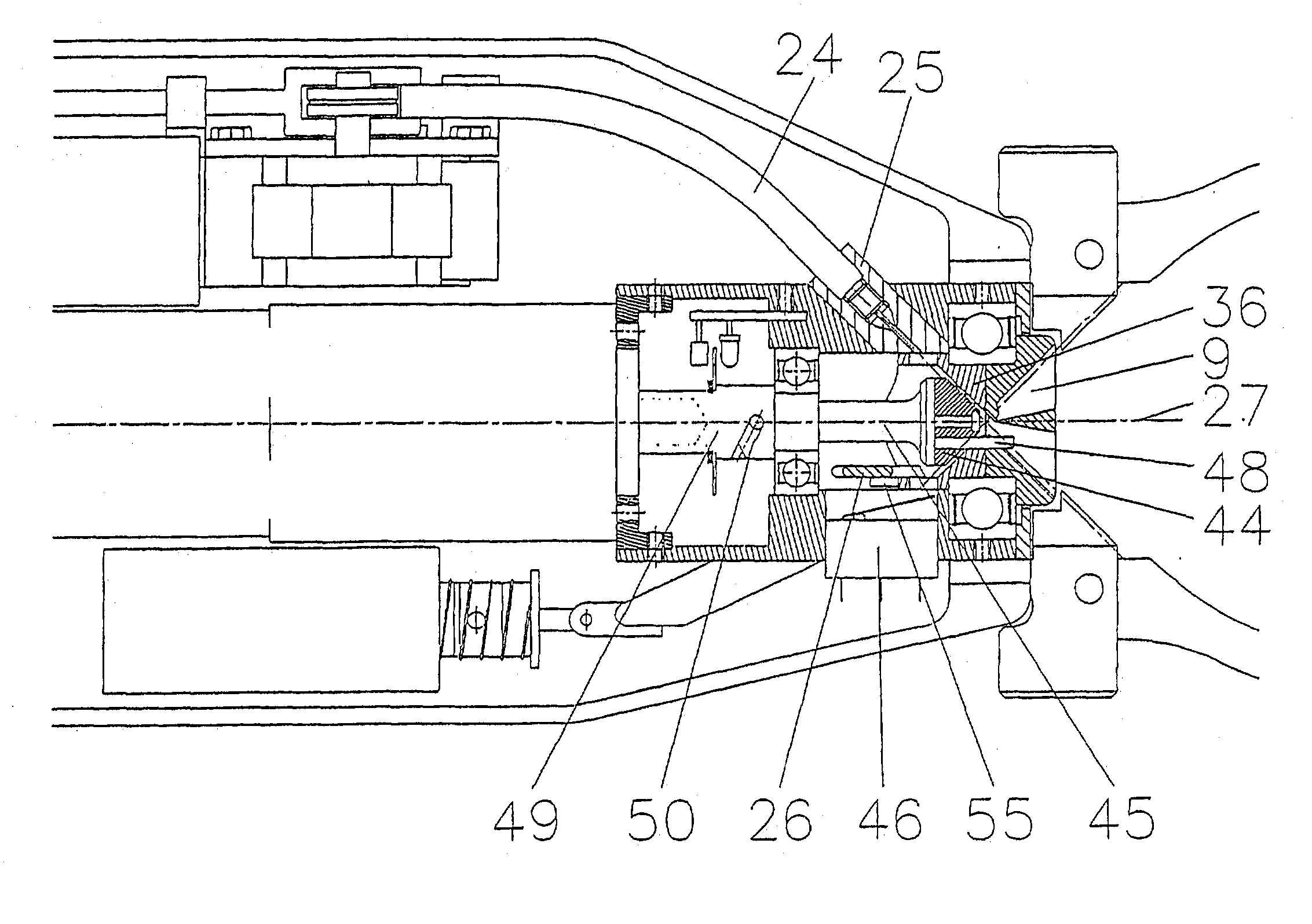

[0074] FIG. 2b shows details of a binder according to an alternative embodiment,

[0075] FIG. 3 shows details of the binder of FIGS. 1 and 2,

[0076] FIG. 4 shows the binder seen from above,

[0077] FIG. 5 shows an alternative embodiment of the binding arrangement,

[0078] FIG. 6 shows a preferred embodiment a polar head,

[0079] FIG. 7 shows a binding head,

[0080] FIG. 8 shows a spindle,

[0081] FIG. 9 shows a binder housing,

[0082] FIG. 10 shows a wire nozzle,

[0083] FIG. 11 shows an axial tightening device,

[0084] FIG. 12 shows a wire spindle lock,

[0085] FIG. 13 shows a wire lock,

[0086] FIG. 14 shows a sliding platform,

[0087] FIG. 15 shows the jaw attachment base,

[0088] FIG. 16 shows a jaw,

[0089] FIG. 17 shows a wire aligning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| mutual distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com