Single/double slurry alternated grouting reinforcement technology of tunnel and device of single/double slurry alternated grouting reinforcement technology

A dual-liquid slurry and alternate injection technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of slow solidification time of single-liquid slurry and small filling range of double-liquid slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

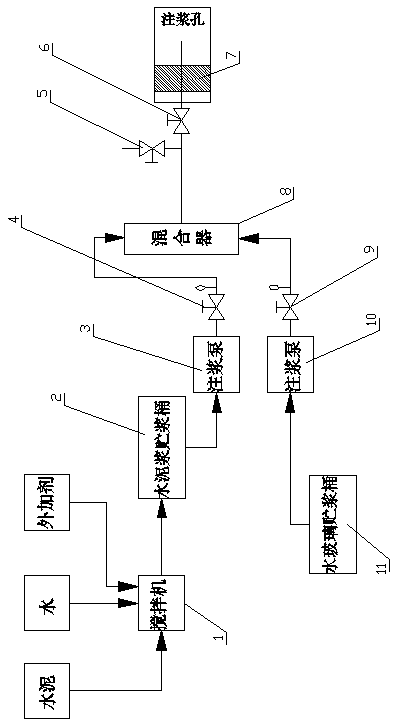

[0016] This kind of tunnel single- and double-fluid alternate grouting reinforcement technology, first select the grouting hole position, after the hole position is arranged, lead the hole and bury the grouting pipe, and then connect the grouting pipeline to prepare for grouting, as in figure 1 as shown,

[0017] 1) Slurry preparation, component A is formulated as cement slurry, including water, cement and admixtures, with a water-cement ratio of 0.8 to 0.9, stirred evenly and then flowed into the cement slurry storage tank 2, component B uses water glass solution, A, Component B is connected to the grouting pump through the pipeline and then enters the mixer 8 to mix to form cement and water glass double liquid slurry;

[0018] 2) Grouting, close the water glass solution valve 9, open the cement slurry valve 4, inject the pure single-liquid cement slurry first, and then open the water glass solution valve 9 for mixed injection. The injection interval between single and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com