Paving brick for purifying air and preparation method thereof

A technology for purifying air and pavement bricks, applied in chemical instruments and methods, manufacturing tools, ceramic molding machines, etc., can solve problems such as inability to purify the environment, inability to absorb harmful gases, etc., to achieve a wide range of uses, good degradability, and broad market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

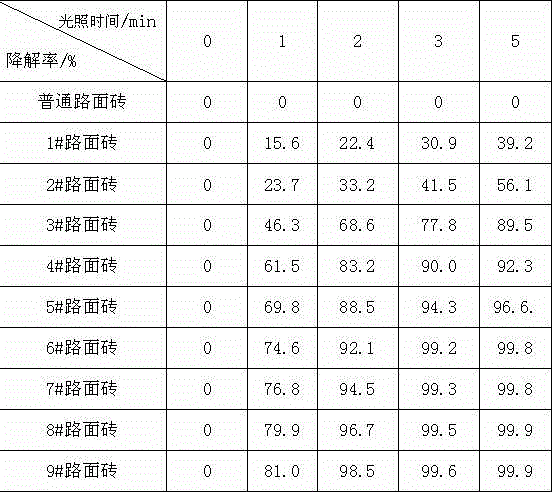

Examples

Embodiment 1

[0022] Example 1: Weigh and measure cement, yellow sand, anatase nano-scale titanium dioxide, pigments, and polycarboxylate-based high-performance water reducers at a ratio of 1:3:0.2:0.03:0.01, and first weigh the Add yellow sand, cement, anatase nano-scale titanium dioxide, and pigments into planetary forced mixer in turn, dry mix for 30s, mix thoroughly, then add 1 / 2 water and stir for 30s according to the water-cement ratio of 0.28, and finally add the rest 1 / 2 of the water and polycarboxylate high-performance water-reducing agent were stirred for 1.5 minutes for later use to prepare pavement brick surface materials for later use; Proportional weighing measurement, first add the weighed yellow sand, gravel, and cement into the planetary forced mixer in turn, dry mix for 30 seconds, mix well, and then add water and polycarboxylate high-performance water reducing The agent was stirred for 2 minutes and set aside; then the prepared pavement brick surface material and bottom l...

Embodiment 2

[0023] Example 2: Weigh and measure cement, yellow sand, titanium dioxide, pigments, and polycarboxylic acid-based high-performance water reducers at a ratio of 1:3:0.3:0.03:0.01, and first weigh the weighed yellow sand, cement, and titanium dioxide Add the pigments to the planetary forced mixer in turn, dry mix for 45s, mix well, then add 1 / 2 water and stir for 30s according to the water-cement ratio of 0.28, and finally add all the water and polycarboxylate high-performance water reducer and stir 2 minutes for later use, prepare pavement brick surface layer materials for later use; weigh and measure cement, yellow sand, gravel, and water reducing agent according to the ratio of 1:3:2:0.01, and first weigh the yellow sand, gravel, The cement is added to the planetary forced mixer in turn, dry mixed for 45 seconds, fully mixed evenly, and then water and polycarboxylate high-performance water reducer are added according to the water-cement ratio of 0.27 and stirred for 2 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com