Pressure bearing and leakage blocking agent

A technology of plugging agent and activator, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of easy channeling, contamination of drilling fluid, poor adhesion, etc. , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

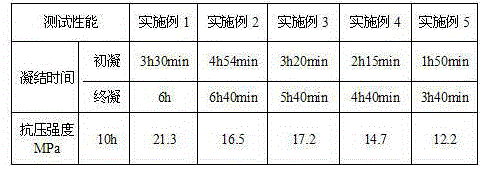

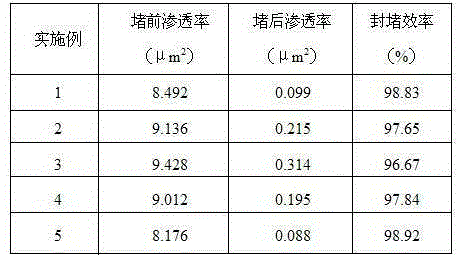

Examples

Embodiment 1

[0023] Pressure-bearing plugging agent formula: 22mL of sodium silicate solution with a concentration of 36% and a modulus of 3.3, 5.73g of sodium hydroxide dry powder, 18mL of clear water, 50g of metakaolin, 0.01g of modified polypropylene fiber, and 1g of 80-100 mesh mica flakes , 100~200 mesh walnut shell 2g, 800 mesh calcium carbonate 5g, curing temperature 60°C.

[0024] Specific preparation process:

[0025] (1) Mix sodium silicate solution, sodium hydroxide and water, stir for 30 minutes, and prepare a sodium silicate solution with a concentration of 20% and a modulus of 1.0;

[0026] (2) Weigh metakaolin, mix it into the above solution, and stir for 20 minutes;

[0027] (3) Add the filling material while stirring. There is no special regulation for the order of addition. After all the addition is completed, stir for 10 minutes;

[0028] (4) Put it in a constant temperature and humidity box for curing, monitor the initial and final setting time of the slurry, and meas...

Embodiment 2

[0030] Concentration 36%, modulus 3.3 sodium silicate solution 21mL, sodium hydroxide dry powder 5.37g, clear water 29mL, metakaolin 50g, modified polypropylene fiber 0.01g, 80~100 mesh mica flakes 2g, 100~200 mesh sawdust 5g, 1250 mesh calcium carbonate 2g, curing temperature 60°C.

Embodiment 3

[0032] Concentration 36%, modulus 3.3 sodium silicate solution 21mL, sodium hydroxide dry powder 4.09g, water 29mL, metakaolin 50g, boric acid 0.02g, sodium hexametaphosphate 0.01g, modified polypropylene fiber 0.02g, 80~100 Mesh mica sheet 1g, 100~200 mesh vermiculite 4g, 1250 mesh calcium carbonate 5g, curing temperature 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com