Method for preparing geological polymeric material by using low-grade kaolin

A technology of geopolymerization and kaolin, which is applied in the field of preparation of geopolymer materials to achieve the effects of improving strength performance, expanding the range of raw materials, and improving geopolymer activity

Inactive Publication Date: 2012-06-27

HUNAN UNIV OF SCI & TECH

View PDF2 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a new method for preparing geopolymeric materials using low-grade kaolin for the defects existing in the existing technology for preparing geopolymeric materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

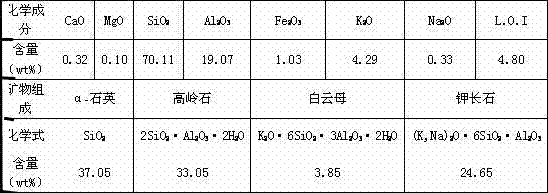

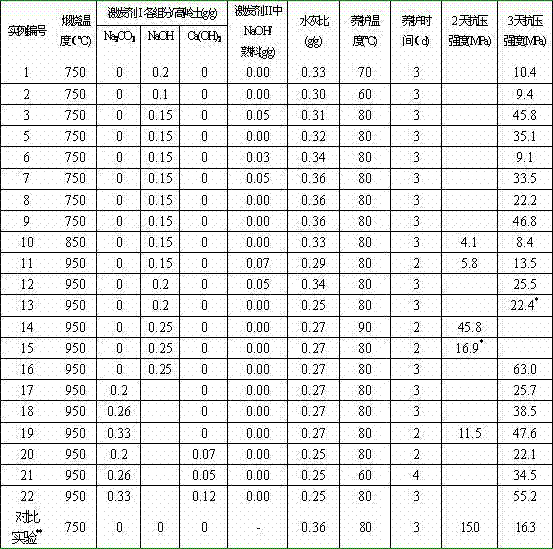

The invention discloses a method for preparing a geological polymeric material by using low-grade kaolin. The method comprises the following steps (1) uniformly mixing low-grade kaolin and an activator I in a certain proportion, wherein the mass ratio of particle size of solid phase in a mixture to material residue on sieve with 200 meshes is less than10%; (2)insulating calcining the mixture in the step (1) at high temperature of 750-950 DEG C for 2-4 hours, grinding the calcined product to obtain the clinker powder, the mass ratio of clinker powder particle size to material residue on sieve with 200 meshes is less than10%; (3) adding an water solution of an activator II in the clinker powder obtained in the step (2), uniformly mixing, vibrating and compacting, keeping the moisture and conserving at 60-90 DEG C for 2-4 days to obtain the geological polymer material; wherein, the water cement ratio of activator II water solution to clinker powder is 0.2 0.4, and the mass ratio of solid phase in activator II to calcined clinker powder is 0 0.07. The present invention has obvious significance for expanding the sources of raw materials, reducing the cost and improving the use convenience.

Description

technical field [0001] The invention belongs to the field of new cement materials, and in particular relates to a method for preparing geopolymeric materials by using low-grade kaolin. Background technique [0002] Geopolymeric materials (referred to as geopolymers), also known as mineral polymeric materials, geopolymeric cements, alkali-activated cements, etc., are an eco-friendly silica-alumina inorganic material that has been developed in recent years and is expected to replace Portland cement. gelling material. It mainly refers to zeolite-like three-dimensional aluminosilicate mineral polymers containing various amorphous to semi-crystalline. Its typical preparation procedure is: silicon-aluminum raw material → calcination activation → soluble alkali metal aluminosilicate dissolution activation → 20-120 ℃ heat preservation and curing. Geopolymer has rich sources of raw materials, low carbon emissions, low expansion and contraction rate, low permeability, rapid early ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B7/02C04B7/42

Inventor 彭美勋王正红

Owner HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com