High early-strength high-performance concrete mixed with nano silicon dioxide powder and preparation method thereof

A technology of nano-silica and high-performance concrete, which is applied in the field of civil engineering concrete, can solve the problem of less nano-SiO2 being added, and achieve the effect of significant technical and economic significance, improvement of compressive strength, and improvement of concrete strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A seaport project uses self-compacting high-strength freeze-thaw-resistant concrete. The raw materials and properties used are as follows:

[0035] Cement: PI42.5 Portland cement, purchased from Nanjing Yuhua Cement Factory.

[0036] Fine aggregate: river sand, fineness modulus 2.3, medium sand; apparent density 2.57g / cm 3 , rinse and dry before use.

[0037] Coarse aggregate: high-density limestone with a nominal particle size of 5-35mm and an apparent density of 2.85g / cm 3 .

[0038] Water: tap water.

[0039] Water reducer: polycarboxylate water reducer, water reducing rate 42%. Purchased from Nanjing Pioneer Technology Industrial Co., Ltd.

[0040] nano-SiO 2 Powder: Nano SiO 2 The content is greater than 99.5%, and the particle size is 30±5nm. Purchased from Hangzhou Wanjing New Material Co., Ltd.

[0041] According to the "Ordinary Concrete Mix Design Regulations (JGJ55-2011)", the concrete mix design is as follows (sand ratio 37%, water-cement ratio 0.4)...

Embodiment 2

[0047] Raw materials:

[0048] Cement: Conch brand PC42.5 composite portland cement

[0049] Fine aggregate: river sand, fineness modulus 2.3, medium sand; apparent density 2.65g / cm 3 , rinse and dry before use.

[0050] Coarse aggregate: basalt crushed stone in Nanjing area, with a nominal particle size of 5-35mm.

[0051] Water: Nanjing tap water.

[0052] Water-reducing agent: Richlam240 naphthalene-based concrete high-efficiency water-reducing agent produced by Nanjing Pioneer Technology Industrial Co., Ltd., with a water-reducing rate of 25%.

[0053] nano-SiO 2 Powder: Nano-SiO produced by Zhejiang Hangzhou Wanjing New Material Co., Ltd. 2 Powder, nano substance content greater than 99.5%, average particle size 30nm, specific surface area 200mm 2 / g, the weight loss on ignition rate is 3.5%.

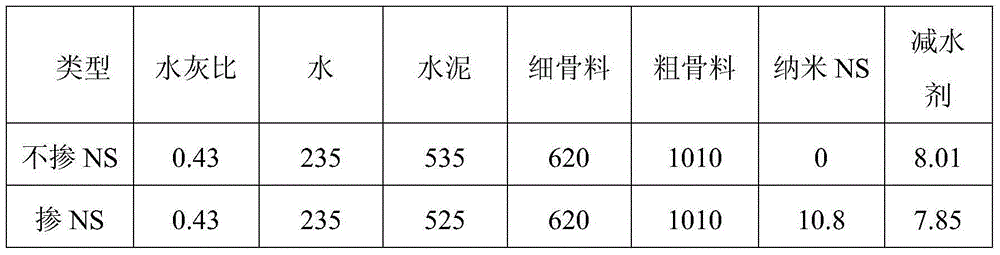

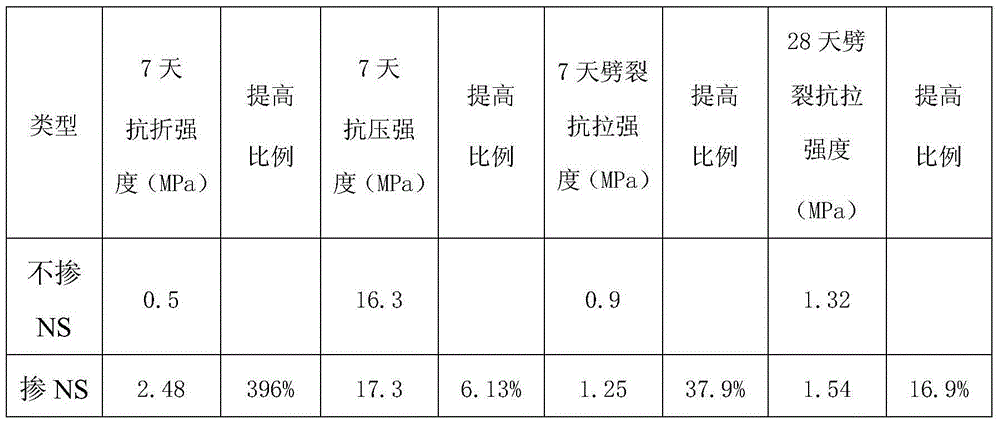

[0054] This example sets to add nano-SiO 2 Early-strength concrete with powder and without adding nano-SiO 2 Ordinary concrete with powder, in accordance with "Common Conc...

Embodiment 3

[0060] Raw materials:

[0061] Cement: Conch brand PC32.5 composite Portland cement

[0062] Fine aggregate: river sand, fineness modulus 2.3, medium sand; apparent density 2.65g / cm 3 , rinse and dry before use.

[0063] Coarse aggregate: basalt crushed stone in Nanjing area, with a nominal particle size of 5-35mm.

[0064] Water: Nanjing tap water.

[0065] Water-reducing agent: Richlam240 naphthalene-based concrete high-efficiency water-reducing agent produced by Nanjing Pioneer Technology Industrial Co., Ltd., with a water-reducing rate of 25%

[0066] nano-SiO 2 Powder: Nano-SiO produced by Zhejiang Hangzhou Wanjing New Material Co., Ltd. 2 Powder, nano substance content greater than 99.5%, average particle size 30nm, specific surface area 200m 2 / g, the weight loss on ignition rate is 3.5%.

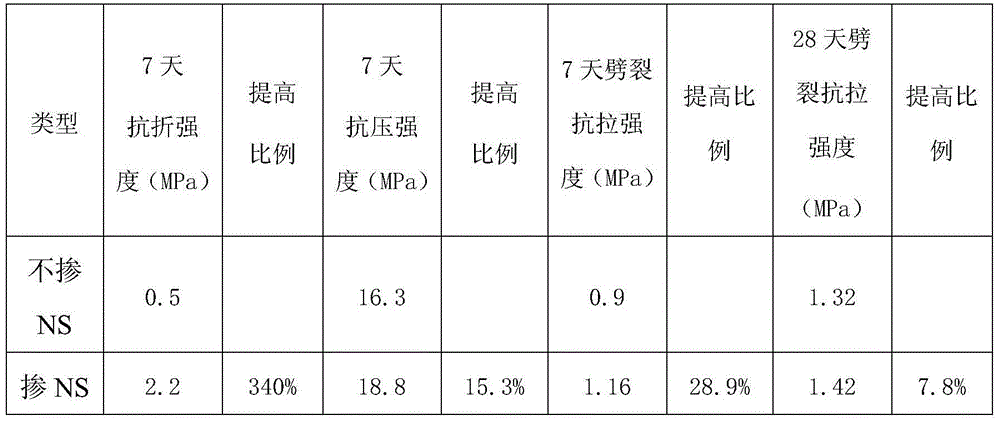

[0067] This example sets to add nano-SiO 2 Early-strength concrete with powder and without adding nano-SiO 2 Ordinary concrete with powder, in accordance with "Common Concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com