Recoverable ground source heat pump

a ground source heat pump and heat sink technology, applied in heat pumps, domestic cooling devices, lighting and heating devices, etc., can solve the problems of limiting the overall cost effectiveness limiting the application of ground source heat pumps for buildings without a large open space, and high initial cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment

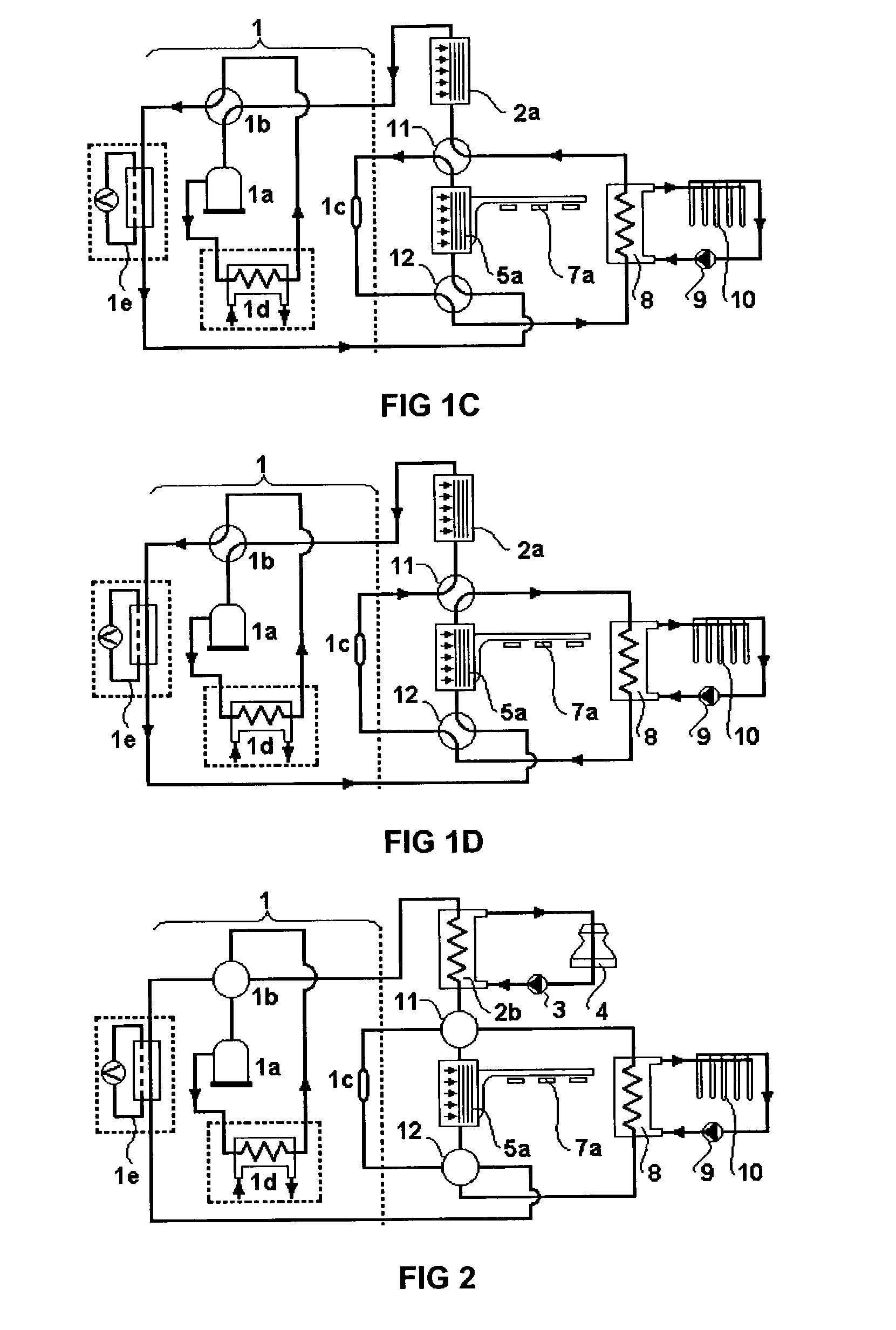

DESCRIPTION--FIG. 6--ALTERNATIVE EMBODIMENT

[0089] FIG. 6. shows an alternative looping of the heat pump system with two forced air-to-fluid heat exchangers used as in-door and out-door heat transfer equipment.

[0090] In this application, the system is simplified to use only two heat exchangers, out-door heat exchanger 2b and in-door heat exchanger 5a. Heat exchanger 2b has to be fluid-to-fluid type and connected to ground loops 10. The in-door heat transfer equipment 7a must be an air-to-fluid heat exchanger. The duct work attached to the heat exchanger 7a is divided into to directions. A reversing valve 13 is installed to change the direction of the forced air to in-door or out door space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com