Mineral-element detergent and preparation method thereof

A mineral element, detergent technology, applied in inorganic/elemental cleaning compositions, chemical instruments and methods, detergent compounding agents, etc., can solve the problem of no detergent found, achieve low cost, good bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

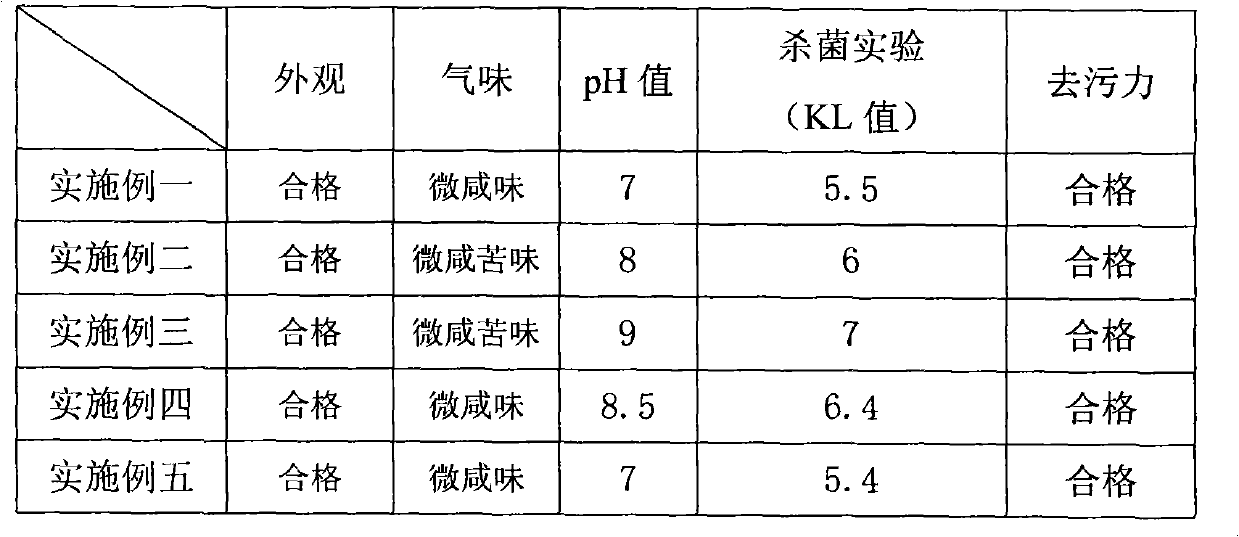

Examples

Embodiment 1

[0030] Raw material proportions are as follows:

[0031] Salt Lake Water Concentrate 20g

[0032] Ionic surfactant 5g

[0033] Non-ionic surfactant 5 grams

[0034] Chinese herbal extract 10g

[0035] Emollient 0.5 g

[0036] Co-solvent 0.5g

[0037] Antifreeze 0.5g

[0038] The rest is deionized water;

[0039] The preparation process of salt lake water concentrate: take 100 kg of salt lake water from Yuncheng, Shanxi, filter it through a sand filter to remove particulate matter, then pass through an activated carbon filter bed, and finally treat it with an ozone treatment device, where the concentration of ozone is 13.6mg / m 3 ≤O 3 Concentration≤40mg / m 3 , and adjust the pH value of the salt lake water to 8; inject the treated lake water into the finished product pool, evaporate and dehydrate, spray dry after reaching a certain concentration, and finally make the dry matter through ultrafine grinding to obtain 20 kg of salt lake water concentrate powder;

[0040] The...

Embodiment 2

[0043] Raw material proportions are as follows:

[0044] Salt Lake Water Concentrate 35g

[0045] ionic surfactant 10g

[0046] 10g non-ionic surfactant

[0047] Chinese herbal extract 15g

[0048] Emollient 5g

[0049] Co-solvent 5 g

[0050] Antifreeze 5 grams

[0051] The rest is deionized water;

[0052] The preparation process of salt lake water concentrate: take 100 kg of Qaidam salt lake water, filter it through a sand filter to remove particulate matter, then pass through an activated carbon filter bed, and finally treat it with an ozone treatment device, where the concentration of ozone is 13.6mg / m 3 ≤O 3 Concentration≤40mg / m 3 , and adjust the pH value of the salt lake water to reach 9; inject the treated lake water into the finished product pool, evaporate and dehydrate, spray dry after reaching a certain concentration, and finally make 25 kg of salt lake water concentrate powder through ultrafine pulverization of the dry matter;

[0053] The preparation proc...

Embodiment 3

[0056] Raw material proportions are as follows:

[0057] Salt Lake Water Concentrate 25g

[0058] Ionic surfactant 7g

[0059] Non-ionic surfactant 8 grams

[0060] Chinese herbal extract 12g

[0061] Emollient 4 g

[0062] Co-solvent 3 g

[0063] Antifreeze 4 grams

[0064] The rest is deionized water;

[0065] The preparation process of salt lake water concentrate: take 100 kg of Qaidam salt lake water, filter it through a sand filter to remove particulate matter, then pass through an activated carbon filter bed, and finally treat it with an ozone treatment device, where the concentration of ozone is 13.6mg / m 3 ≤O 3 Concentration≤40mg / m 3 , and adjust the pH value of the salt lake water to reach 9; inject the treated lake water into the finished product pool, evaporate and dehydrate, spray dry after reaching a certain concentration, and finally make 25 kg of salt lake water concentrate powder through ultrafine pulverization of the dry matter;

[0066] The preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com