Vibration-press-free water stabilizing additive, and preparation and application thereof

An additive and water stabilization technology, applied in instruments, analytical materials, measuring devices, etc., can solve the problems of reducing the relative mass of cement and aggregate, reducing the strength of cement stabilized crushed stone, slow testing process, etc., to reduce construction disturbance, The effect of improving workability and reducing water usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

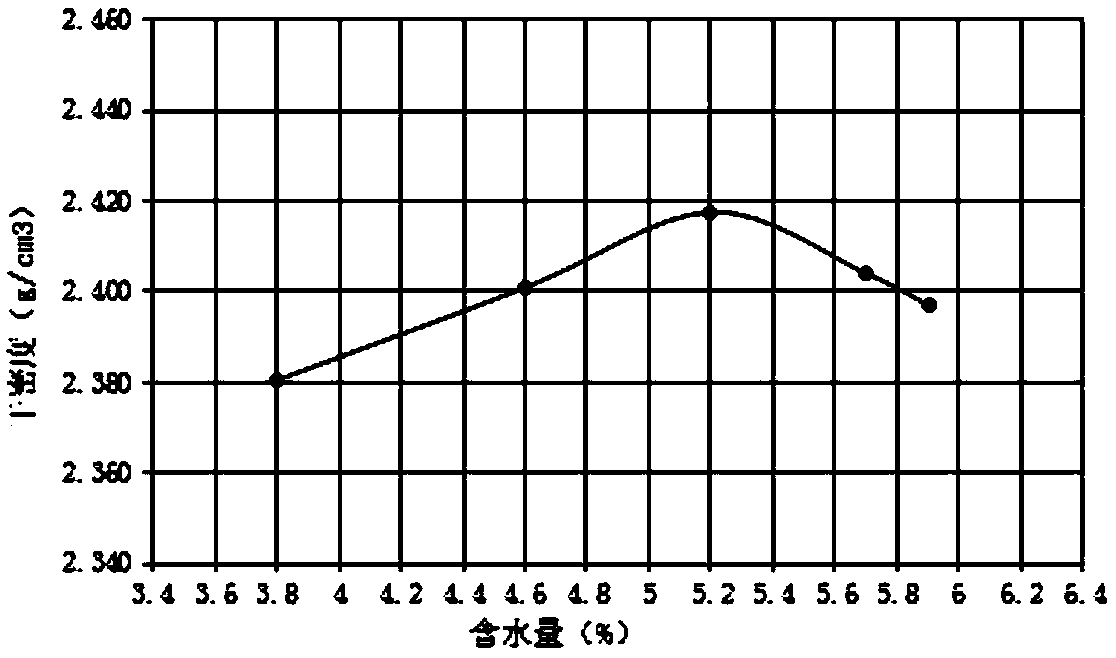

Embodiment 1

[0051] A method for measuring the maximum dry density using a pressure-free water stabilization additive:

[0052] S1: Drying: Place aggregates mixed with Zhejiang Huzhou limestone and Zhejiang Maodi basalt in an oven at a temperature of 105°C, and dry for 5 hours until the weight of the aggregate remains constant;

[0053] S2: Preparation of sample: Mix the dried aggregate, cement, water and anti-vibration pressure water stabilization additive (water reducer: expansion agent = 1.5:7.5) in the ratio of 246.9:11.1:12.3:1 in S1 , prepare the vibration-free cement stabilized crushed stone sample, and dry it;

[0054] S3: Preparation of dry mixture: take the dried sample m 1 grams, m 1 = ρ dmax ×2680×(1-0.01×P), mixed with m 2 gram of cement is fully mixed to obtain a uniform dry mixture, the m 2 = m 1 *0.01*p, where:

[0055] ρ dmax The maximum dry density (g / cm3) of the mixture determined for static pressure compaction,

[0056] P is the preset cement dosage (%);

[00...

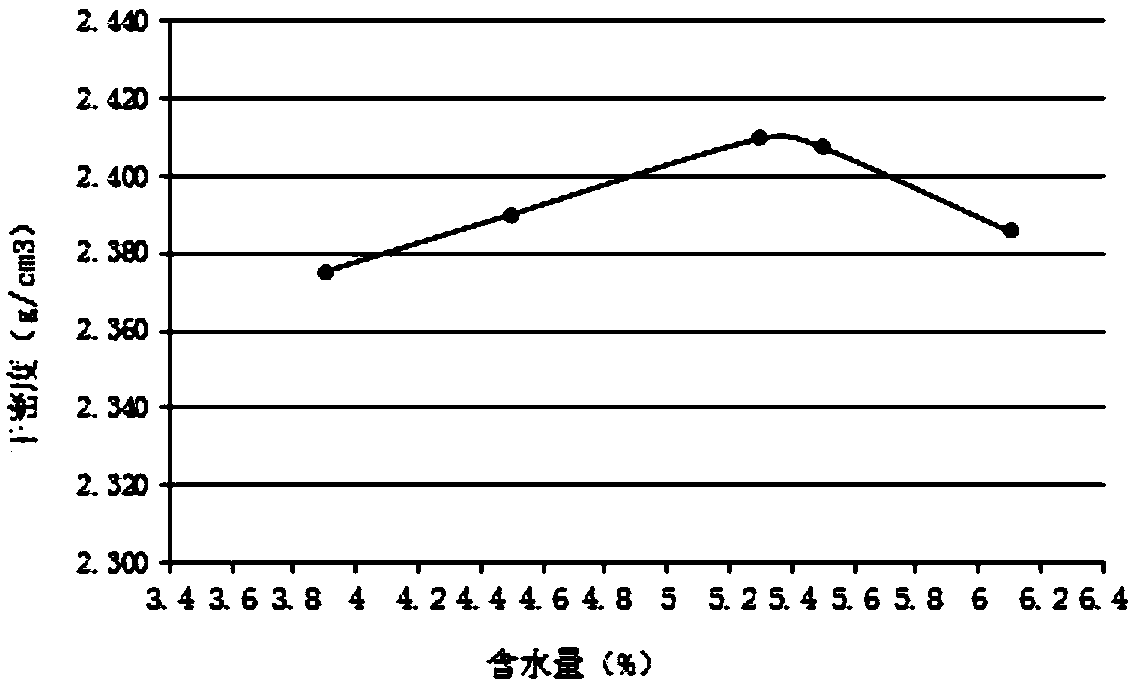

Embodiment 2

[0071] A method for measuring the maximum dry density using a pressure-free water stabilization additive:

[0072] S1: Drying: Place limestone aggregates of three sizes: 31.5-16mm, 16-5mm, and 5-0mm in an oven at a temperature of 108°C, and dry for 6 hours until the weight of the aggregate remains constant;

[0073] S2: Preparation of sample: Mix the dried aggregate, cement, water and anti-vibration pressure water stabilization additive (water reducer: expansion agent = 2.5:8.5) in the ratio of 202:9.1:10.1:1 in S1 , prepare the vibration-free cement stabilized crushed stone sample, and dry it;

[0074] S3: Preparation of dry mixture: take the dried sample m 1 grams, m 1 = ρ dmax ×2650.72×(1-0.01×P), mixed with m 2 gram of cement is fully mixed to obtain a uniform dry mixture, the m 2 = m 1 *0.01*p, where:

[0075] ρ dmax The maximum dry density (g / cm3) of the mixture determined for static pressure compaction,

[0076] P is the preset cement dosage (%);

[0077] S4: ...

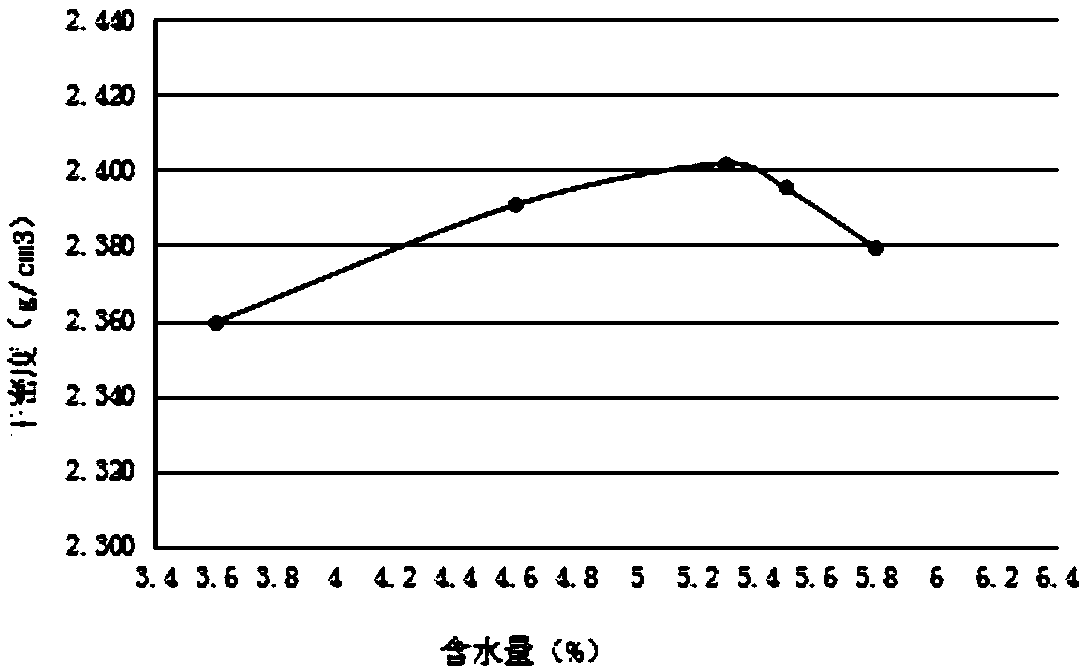

Embodiment 3

[0091] A method for measuring the maximum dry density using a pressure-free water stabilization additive:

[0092] S1: Drying: Place limestone aggregates of three sizes: 31.5-16mm, 16-5mm, and 5-0mm in an oven at a temperature of 108°C, and dry for 6 hours until the weight of the aggregate remains constant;

[0093] S2: Prepare the sample: mix the dried aggregate, cement, water and vibration-free water stabilization additive in S1 according to the proportion, prepare the vibration-free cement stabilized gravel sample, and dry it;

[0094] S3: Preparation of dry mixture: take the dried sample m 1 grams, m 1 = ρ dmax ×2667.5×(1-0.01×P), mixed with m 2 gram of cement is fully mixed to obtain a uniform dry mixture, the m 2 = m 1 *0.01*p, where:

[0095] ρ dmax The maximum dry density (g / cm3) of the mixture determined for static pressure compaction,

[0096] P is the preset cement dosage (%);

[0097] S4: Prepare the wet mixture: fully mix the dry mixture with water, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com