Water-based cutting fluid and preparation method thereof

A cutting fluid, water-based technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of poor extreme pressure wear resistance, poor rust resistance, ineffective cooling, etc., to inhibit the oxidation process, reduce wear, Prolong the effect of oil use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

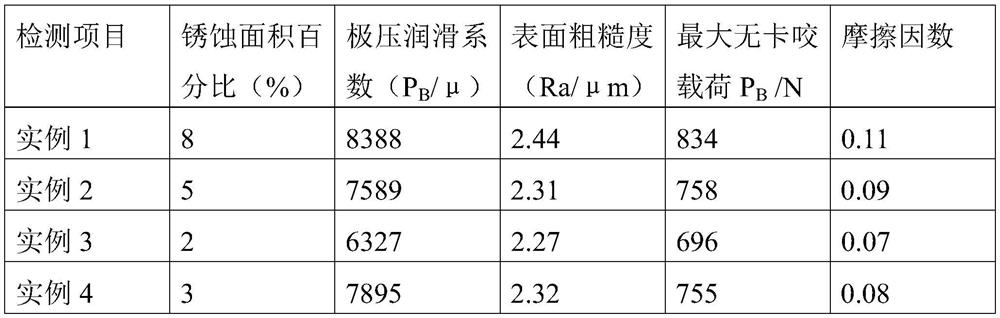

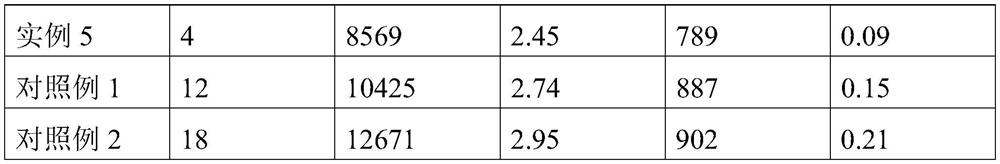

Examples

example 1

[0037] (1) In parts by weight, weigh 45 parts of 2,6-di-tert-butyl-p-cresol, 10 parts of molybdenum disulfide and 35 parts of oxymolybdenum dialkyldithiocarbamate and mix to obtain a molybdenum lubricant ;

[0038] (2) Mix the above-mentioned molybdenum-based lubricant with O, O-dialkyl dithiophosphate, stir and react at 45°C for 25 minutes, and discharge to obtain a modified molybdenum-based lubricant;

[0039] (3) In parts by weight, weigh 1 part of triethanolamine borate, 1 part of defoamer DT-135, 1 part of bactericide, 30 parts of modified molybdenum lubricants and 40 parts of pure water, and put the antirust Put agent, defoamer, borax, and modified molybdenum lubricant into pure water, stir at 40°C for 30 minutes, and then add an appropriate amount of triethanolamine to adjust the pH to 8 to obtain a water-based cutting fluid.

example 2

[0041] (1) In parts by weight, weigh 45 parts of 2,6-di-tert-butyl-p-cresol, 10 parts of molybdenum disulfide and 35 parts of oxymolybdenum dialkyldithiocarbamate and mix to obtain a molybdenum lubricant ;

[0042] (2) Mix the above-mentioned molybdenum-based lubricant with O, O-dialkyl dithiophosphate, stir and react at 45°C for 25 minutes, and discharge to obtain a modified molybdenum-based lubricant;

[0043] (3) In parts by weight, take 2 parts of triethanolamine borate, 2 parts of defoamer DT-135, 1 part of bactericide, 32 parts of modified molybdenum lubricants and 42 parts of pure water, and rust-proof Put agent, defoamer, borax, and modified molybdenum lubricant into pure water, stir at 42°C for 32 minutes, and then add an appropriate amount of triethanolamine to adjust the pH to 8 to obtain a water-based cutting fluid.

example 3

[0045] (1) In parts by weight, weigh 45 parts of 2,6-di-tert-butyl-p-cresol, 10 parts of molybdenum disulfide and 35 parts of oxymolybdenum dialkyldithiocarbamate and mix to obtain a molybdenum lubricant ;

[0046] (2) Mix the above-mentioned molybdenum-based lubricant with O, O-dialkyl dithiophosphate, stir and react at 45°C for 25 minutes, and discharge to obtain a modified molybdenum-based lubricant;

[0047] (3) In parts by weight, take 5 parts of triethanolamine borate, 3 parts of defoamer DT-135, 2 parts of fungicides, 35 parts of modified molybdenum lubricants and 50 parts of pure water, and rust-proof Put agent, defoamer, borax, and modified molybdenum lubricant into pure water, stir at 43°C for 35 minutes, and then add an appropriate amount of triethanolamine to adjust the pH to 8 to obtain a water-based cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com