Composite early-strength type polycarboxylate superplasticizer as well as preparation method and application thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of building materials, can solve the problems of waste of natural resources and social resources, increase in the amount of cementitious materials, and increase in comprehensive costs, so as to improve durability, reduce water-cement ratio, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

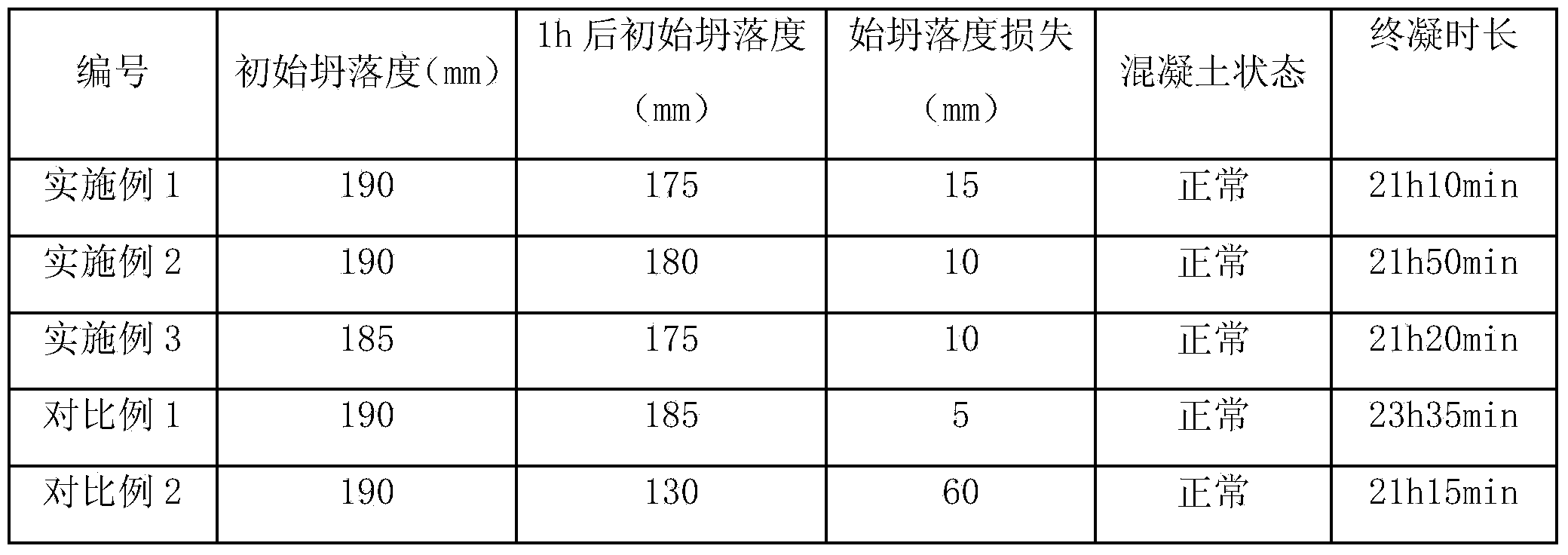

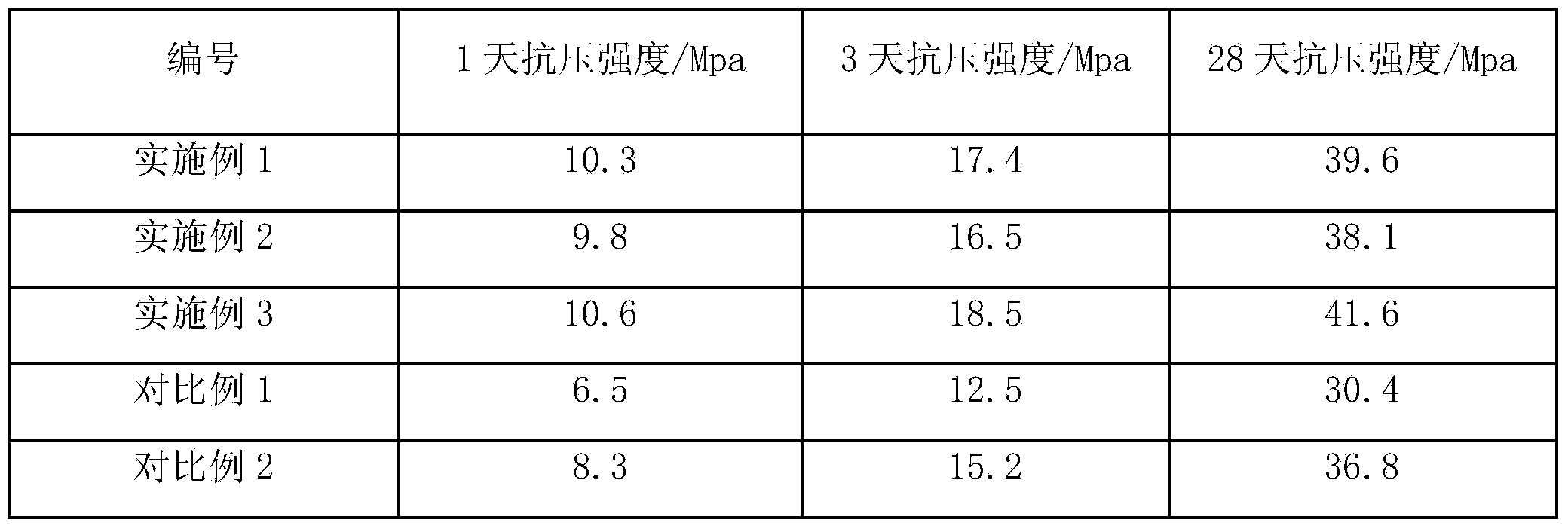

Examples

preparation example Construction

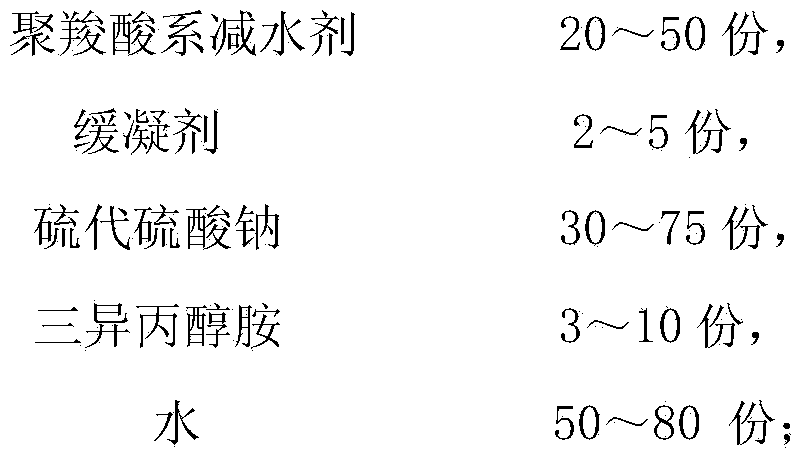

[0034] Further, the present invention also discloses a preparation method of the composite early-strength polycarboxylate superplasticizer, including the following steps:

[0035] a. Mix polycarboxylate water reducer with water;

[0036] b. Then add retarder, sodium thiosulfate and triisopropanolamine, and stir to obtain.

[0037] Wherein, in order to shorten the preparation time and ensure full fusion of the various components, the stirring time in the b step is preferably 10-20 min.

[0038] Furthermore, the present invention also discloses the use of the composite early-strength polycarboxylate water reducer of the present invention in C15-C60 concrete.

[0039] According to GB50010-2010 "Specifications for Concrete Structures", ordinary concrete is divided into fourteen grades, namely: C15, C20, C25, C30, C35, C40, C45, C50, C55, C60, C65, C70, C75, C80 . For example, C30 concrete means 30MPa≤fcu, k<35MPa. C15-C60 here includes concrete with ten strength grades of C15,...

Embodiment 1

[0042] Example 1 Preparation of composite water reducer of the present invention

[0043] Get LonS-Mw water-reducing polycarboxylate mother liquor (ether, 40% solid content, manufacturer Sichuan Jilong Chemical Building Materials Co., Ltd., production batch number 20131207-0) 21kg, after water 79kg mixes evenly, add sodium gluconate 3kg successively , 30kg of sodium thiosulfate and 4kg of triisopropanolamine were stirred for 10 minutes and fully dissolved to obtain a composite early-strength polycarboxylate superplasticizer.

Embodiment 2

[0044] Example 2 Preparation of composite water reducer of the present invention

[0045] Get LonS-Mw water-reducing polycarboxylate mother liquor (ethers, 40% solid content, manufacturer Sichuan Jilong Chemical Building Materials Co., Ltd., production batch number 20131207-0) 30kg, after water 70kg mixes evenly, add sodium gluconate 4kg successively , 45kg of sodium thiosulfate, and 6kg of triisopropanolamine were stirred for 20 minutes and fully dissolved to obtain a composite early-strength polycarboxylate superplasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com