Inorganic environment-friendly manmade art stone and preparation method thereof

An artificial and artistic technology, applied in the field of inorganic and environmentally friendly artificial art stone and its preparation, can solve the problems of insufficient strength and durability, large difference in texture, etc., and achieve the effects of stable product quality, reduced water-cement ratio, and reduced cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

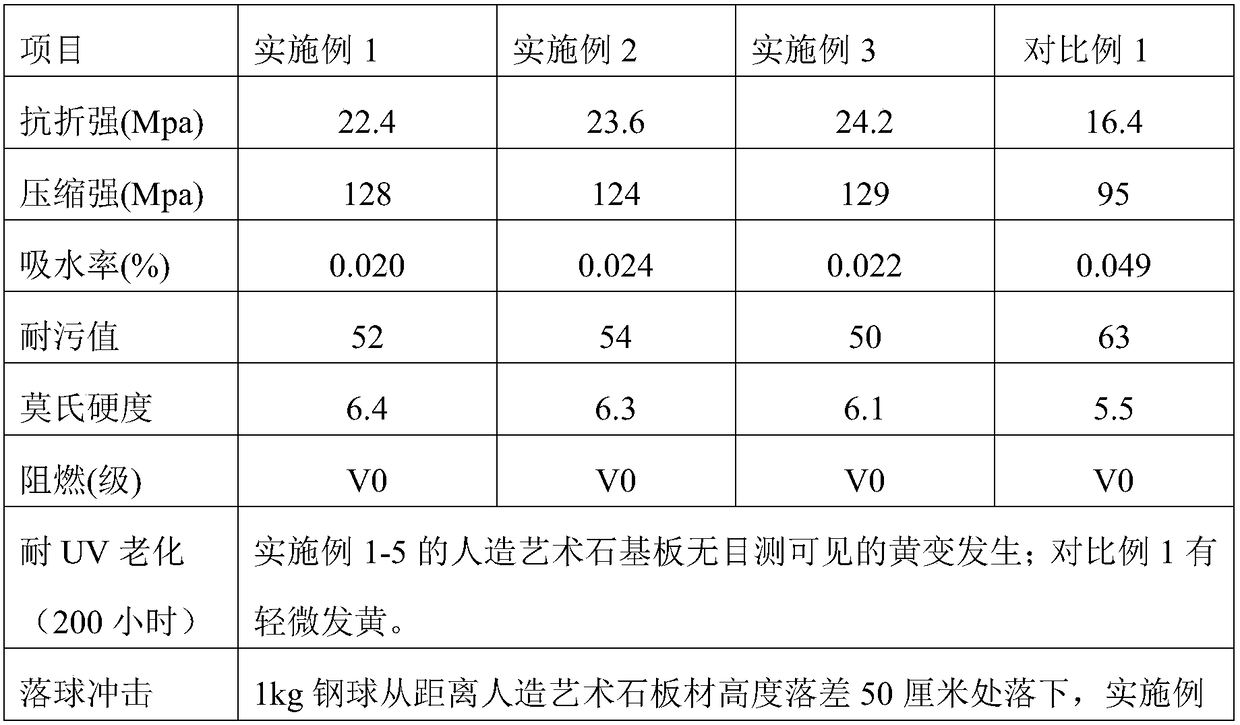

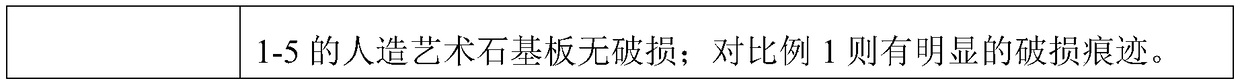

Examples

preparation example Construction

[0026] The present invention also provides the preparation method of above-mentioned artificial art stone, comprises the following steps:

[0027] S1. Mix quartz sand particles, quartz sand powder, cement, active additives, expansion agents, water reducers, emulsions and water retaining agents, add water or ice-water mixture at 0°C, and continue mixing to obtain a mixture for later use;

[0028] S2. Lay a release film on the bottom of the forming mold, spread the mixture evenly on the release film, and cover the surface of the laid mixture with a release film; wherein the release film is a polymer film, glue-coated Kraft paper or metal foil; the polymer film can be polypropylene film, polyethylene film, etc.; the thickness of the release film is 0.05mm-0.2mm;

[0029] S3. Vibrate the mixture under vacuum conditions, 35-45kgf / cm 2 Press under pressure to obtain the blank; the pressure is preferably 40kgf / cm 2 ;The pressing time is 40s~60s;

[0030] S4, put the blank into the...

Embodiment 1

[0035] Prepare the raw materials (×5kg) of artificial art stone according to the following proportions by mass: 55 parts of quartz sand particles, 4 parts of quartz sand powder, 17 parts of cement, 1 part of active additive, 1 part of expansion agent, 3 parts of emulsion, water reducing 0.3 parts of agent, 0.05 parts of water retaining agent, 3 parts of water at 0°C. Among them, the quartz sand particles are a mixture of 16-120 mesh continuous gradation, the quartz sand powder is 325 mesh, the cement is 52.5 ordinary Portland cement (produced by Conch Cement Group), and the active additive is metakaolin (China Zexi Mineral Processing Company SNOWKANO+), the expansion agent is TD-AEA (Shanghai Tongtai Concrete Admixture Company), the emulsion is styrene-butadiene polymer emulsion (BASF 686), and the water reducing agent is polycarboxylate superplasticizer (Shenzhen Wushan New Building Materials Co., Ltd. WS -PC type), the water retaining agent is carboxymethyl cellulose (Hebei ...

Embodiment 3

[0041] Prepare the raw materials (×5kg) of artificial art stone according to the following proportions by mass: 70 parts of quartz sand particles, 9 parts of quartz sand powder, 24 parts of cement, 4 parts of active additives, 2 parts of expansion agent, 5 parts of emulsion, water reducing 0.4 parts of agent, 0.1 part of water retaining agent, 5 parts of water at 0°C. Among them, the quartz sand particles are a mixture of 4-120 mesh continuous gradation, the quartz sand powder is 325 mesh quartz sand powder, the cement is 52.5 ordinary Portland white cement (produced by Anqing Albo), and the active additive is secondary fly ash (produced by Shenzhen Shekou Mawan Power Plant), the expansion agent is low-alkali UEA (Henan Guwen Engineering Technology Co., Ltd.), the emulsion is acrylic polymer emulsion (Sintema Company 509), and the water reducing agent is polycarboxylate high-efficiency water reducing agent (Guangzhou Sihang Building Materials Company WS-PC type), the water ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com