Cement concrete pavement rapid repair material and mortar and preparation method of mortar

A technology for cement concrete and repair materials, which is applied in the field of mortar and preparation, and rapid repair materials for cement concrete pavement. It can solve the problems of brittle cement-based materials and poor repair effects, so as to solve the problems of brittle quality, quickly repair concrete, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

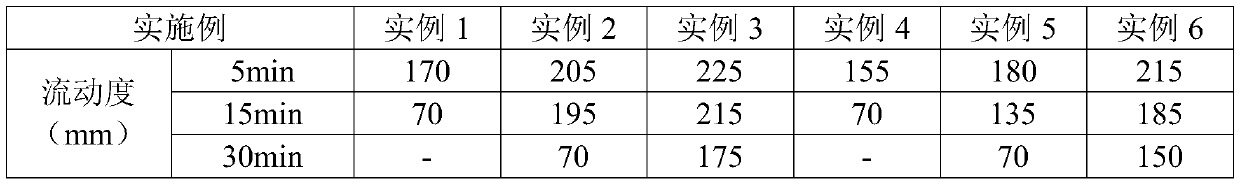

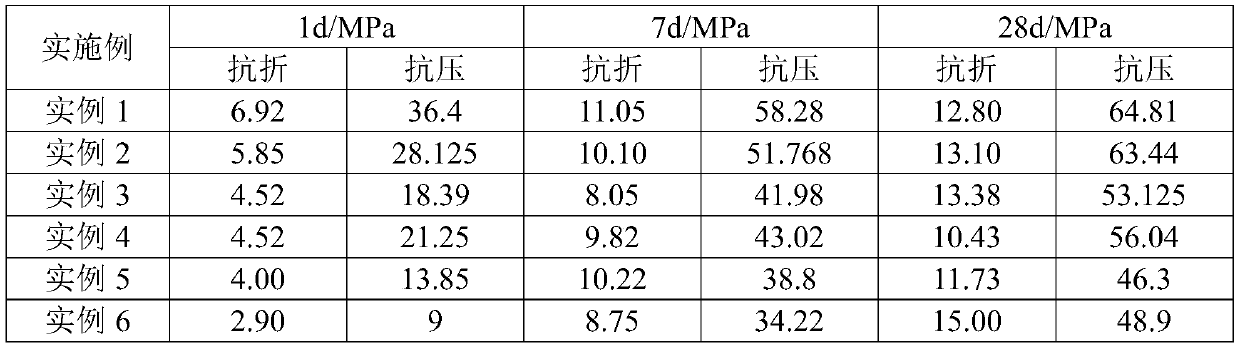

Embodiment 1

[0047] In this example, the components and proportions of the rapid repair mortar for cement concrete pavement are: Portland cement 518g, aluminate cement 112g, hemihydrate gypsum 70g, intermediate sand 1050g, SBR emulsion 62.22g, tap water 210.78g, Aqua 1.5g and defoamer 1.4g.

[0048] The above components were prepared into quick repair mortar, and then the mixture was poured into the mold for curing, and its various properties were tested.

[0049] The preparation process includes the following steps:

[0050] Step 1, add Portland cement, aluminate cement, hemihydrate gypsum and water reducer to the mixing tank to mix and stir evenly;

[0051] Step 2, then add water and polymer emulsion and stir evenly, and stir at 1000rpm for 30s;

[0052] Step 3, then add intermediate sand and stir for 2 minutes at 1000rpm;

[0053] Step 4, reduce the rotation speed to 600rpm, stir for 1 minute, add defoamer 20 seconds before the end of stirring, and stir evenly;

[0054] Step five, p...

Embodiment 2

[0056] In this example, the components and proportions of the rapid repair mortar for cement concrete pavement are: Portland cement 518g, aluminate cement 112g, hemihydrate gypsum 70g, intermediate sand 1050g, SBR emulsion 124.44g, tap water 176.56g, Aqua 1.5g and defoamer 1.4g. The medium-grade sand is the medium-grade sand that meets the requirements of the ISO standard.

[0057] The above components were prepared into quick repair mortar, and then the mixture was poured into the mold for curing, and its various properties were tested.

[0058] The preparation process includes the following steps:

[0059] Step 1, add Portland cement, aluminate cement, hemihydrate gypsum and water reducer to the mixing tank to mix and stir evenly;

[0060] Step 2, then add water and polymer emulsion and stir evenly, and stir at 1000rpm for 30s;

[0061] Step 3, then add intermediate sand and stir for 2 minutes at 1000rpm;

[0062] Step 4, reduce the rotation speed to 600rpm, stir for 1 m...

Embodiment 3

[0065] In this example, the components and proportions of the rapid repair mortar for cement concrete pavement are: Portland cement 518g, aluminate cement 112g, hemihydrate gypsum 70g, intermediate sand 1050g, SBR emulsion 186.67g, tap water 142.33g, Aqua 1.5g and defoamer 1.4g.

[0066] The above components were prepared into quick repair mortar, and then the mixture was poured into the mold for curing, and its various properties were tested.

[0067] The preparation process includes the following steps:

[0068] Step 1, add Portland cement, aluminate cement, hemihydrate gypsum and water reducer to the mixing tank to mix and stir evenly;

[0069] Step 2, then add water and polymer emulsion and stir evenly, and stir at 1000rpm for 30s;

[0070] Step 3, then add intermediate sand and stir for 2 minutes at 1000rpm;

[0071] Step 4, reduce the rotation speed to 600rpm, stir for 1 minute, add defoamer 20 seconds before the end of stirring, and stir evenly;

[0072] Step five, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com