Phosphorus gypsum foam product and method for preparing same

A technology of foamed products and phosphogypsum, which is applied in the field of building materials, can solve the problems of high equipment requirements, poor economic benefits, and high production costs, and achieve the effects of good economic benefits, low cost, and satisfactory performance of molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, steel slag is taken from Wuhan Iron and Steel Co., Ltd., and after drying, it is ground into steel slag powder. According to GB / T8074-2008 "Method for Determination of Cement Specific Surface Area", the Blaine specific surface area is 394m 2 / Kg; The slag is taken from Wuhan Iron and Steel Co., Ltd., and it is ground into slag powder after drying. The measured Blaine specific surface area is: 411m 2 / Kg; Phosphogypsum is obtained from Hubei Huangmailing Phosphorus Chemical Co., Ltd., and dried in an oven at 170°C for 1 hour; the foaming agent is a hydrogen peroxide solution with a mass fraction of 30%; the water reducing agent is a standard polycarboxylic acid reducing agent. Aqua.

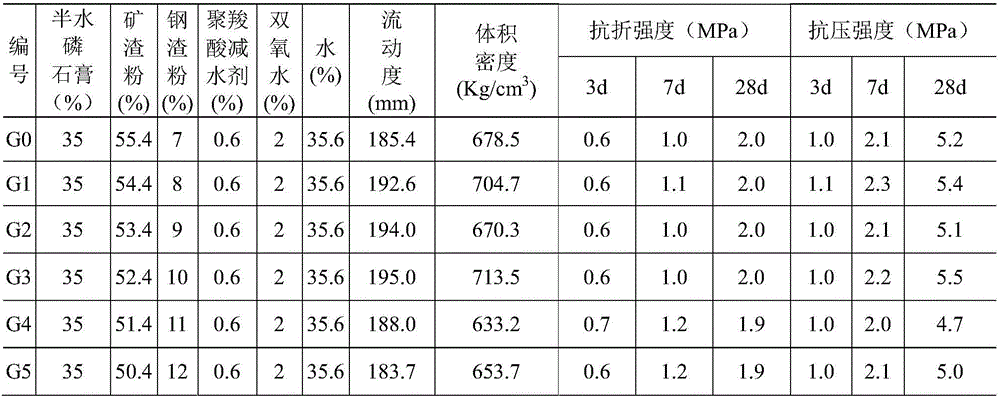

[0028] Phosphogypsum foamed products (numbered G0-G5, with different amounts of steel slag), the raw materials of which include solid waste, admixture and water; wherein, the components in the solid waste and admixture are: steel slag 7%-12% powder, 50.4%-55.4% slag powder...

Embodiment 2

[0037] In this example, steel slag is taken from Wuhan Iron and Steel Co., Ltd., and after drying, it is ground into steel slag powder. According to GB / T8074-2008 "Method for Determination of Cement Specific Surface Area", the Blaine specific surface area is 394m 2 / Kg; The slag is taken from Wuhan Iron and Steel Co., Ltd., and it is ground into slag powder after drying. The measured Blaine specific surface area is: 411m 2 / Kg; Phosphogypsum is taken from Hubei Huangmailing Phosphorus Chemical Co., Ltd., and dried in an oven at 250°C for 0.5 hours; the foaming agent is a hydrogen peroxide solution with a mass fraction of 30%; the water reducing agent is a standard polycarboxylate water reducer .

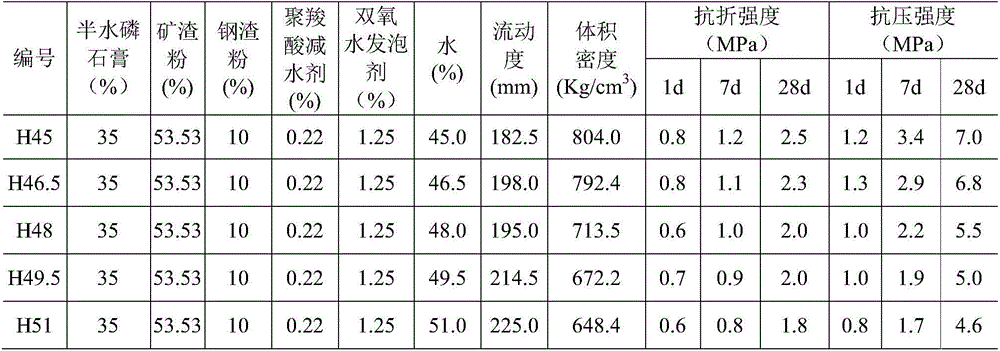

[0038] Phosphogypsum foamed products (numbered H45-H51, with different water additions), the raw materials of which include solid waste, admixture and water; wherein, the components in the solid waste and admixture are: steel slag 10% powder, 53.53% slag powder, 35% phosphogypsum he...

Embodiment 3

[0043] In this example, steel slag is taken from Wuhan Iron and Steel Co., Ltd., and after drying, it is ground into steel slag powder. According to GB / T8074-2008 "Method for Determination of Cement Specific Surface Area", the Blaine specific surface area is 394m 2 / Kg; The slag is taken from Wuhan Iron and Steel Co., Ltd., and it is ground into slag powder after drying. The measured Blaine specific surface area is: 411m 2 / Kg; Phosphogypsum was obtained from Hubei Huangmailing Phosphorus Chemical Co., Ltd., and dried in an oven at 200°C for 0.8 hours; the foaming agent was 30% hydrogen peroxide solution; the water reducer was standard polycarboxylate water reducer.

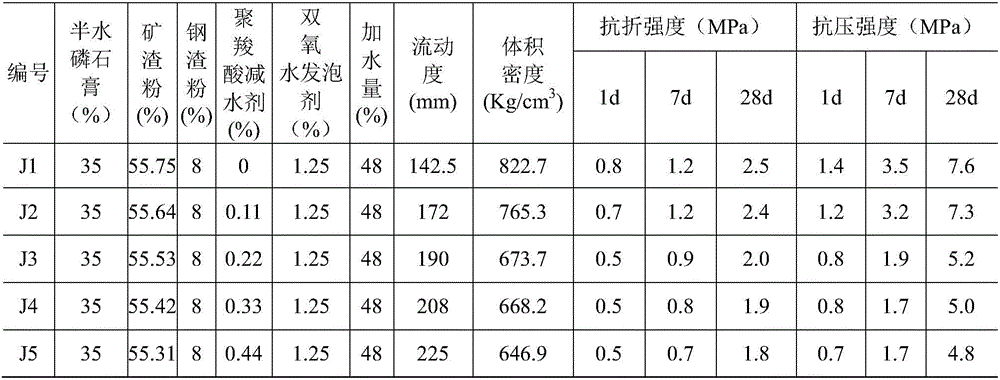

[0044] Phosphogypsum foamed products (numbered J1-J5, the amount of water reducer is different), its raw materials include solid waste, admixture and water; wherein, the components in the solid waste and admixture are : Steel slag powder 8%, slag powder 55.31% ~ 55.75%, phosphogypsum hemihydrate 35%, hydrogen per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blaine specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com