Efficient liquid antifreezing agent for concrete, and preparation method thereof

A concrete and antifreeze technology, which is applied in the field of building materials, can solve the problems of alkali-aggregate reaction, steel bar corrosion, high dosage, etc., achieve high water reduction rate and work performance, reduce water-cement ratio, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

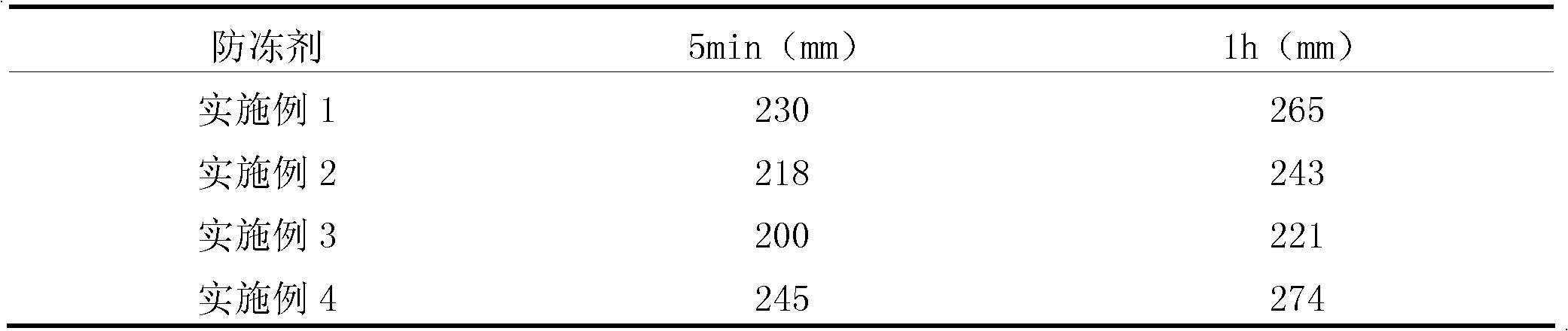

Embodiment 1

[0027] A preparation method for a liquid antifreeze agent for concrete, comprising the steps of:,

[0028] 1) Refer to the following mass ratio ingredients:

[0029] serial number

name

mass (kg)

1

55

2

5.0

3

Organic alcohol amine

2.2

4

45

5

ethylene glycol

55

6

air entraining agent

1.2

7

water

200

[0030] Wherein, the high-efficiency water reducer is Nai series high-efficiency water reducer FDN-5, the formate is calcium formate, the organic alcohol amine is triethanolamine, the carbonate is sodium carbonate, and the air-entraining agent is dodecylbenzene sodium sulfonate.

[0031] 2) Put the high-efficiency water reducer into a container (such as a beaker), add water with a total water content of 30% (60kg), heat to 25°C to 40°C and stir until the high-efficiency water reducer dissolve...

Embodiment 2

[0034] A preparation method for a liquid antifreeze agent for concrete, comprising the steps of:,

[0035] 1) Refer to the following mass ratio ingredients:

[0036] serial number

name

mass (kg)

1

60

2

5.4

3

Organic alcohol amine

2.4

4

carbonate

45

5

65

6

air entraining agent

1.2

7

water

180

[0037] Wherein, the high-efficiency water-reducing agent is Nai series high-efficiency water-reducing agent (HSN), the formate is calcium formate, the organic alcohol amine is triethanolamine, the carbonate is sodium carbonate, and the air-entraining agent is dodecylbenzene sodium sulfonate.

[0038]2) Put the high-efficiency water-reducing agent into the container, add water with 35% of the total amount of water, heat to 25°C-40°C and stir until the high-efficiency water-reducing agent is d...

Embodiment 3

[0041] A preparation method for a liquid antifreeze agent for concrete, comprising the steps of:,

[0042] 1) Refer to the following mass ratio ingredients:

[0043] serial number

name

mass (kg)

1

65

2

5.4

3

Organic alcohol amine

2.6

4

carbonate

45

5

65

6

air entraining agent

1.2

7

water

165

[0044] Wherein, the high-efficiency water reducer is polycondensed acid high-efficiency water reducer (HXJ-1), the formate is calcium formate, the organic alcohol amine is triethanolamine, the carbonate is sodium carbonate, and the air-entraining agent is twelve Sodium Alkylbenzene Sulfonate.

[0045] 2) Put the high-efficiency water reducer into the container, add water with a total water content of 20% (33kg), heat to 25°C-40°C and stir until the high-efficiency water reducer dissolves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com