Waterborne epoxy composite cement mortar material as well as preparation and construction methods thereof

A technology for compounding cement and mortar materials is applied in the field of building construction to achieve the effects of easy leveling of the base surface, easy construction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

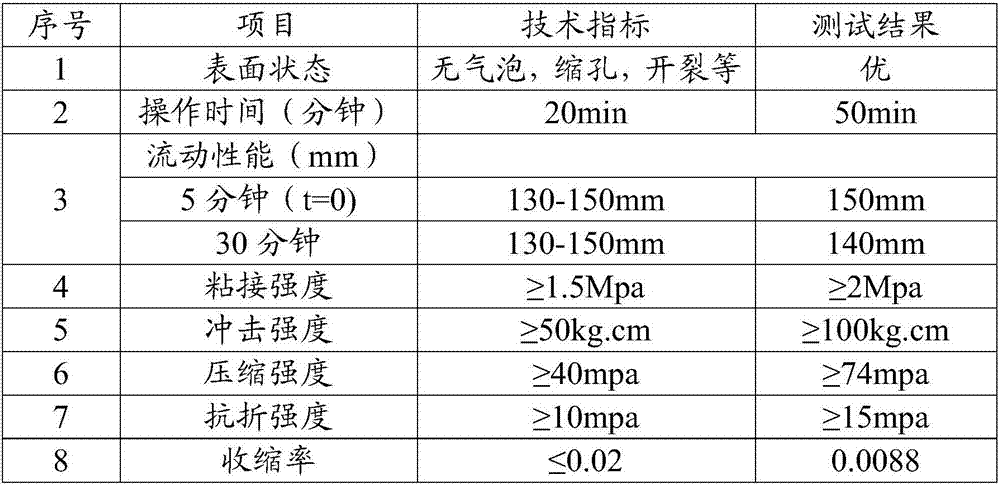

Embodiment 1

[0030] The present embodiment provides a kind of water-based epoxy composite cement mortar material, and described material is made up of component A, component B and component C, and the mass ratio of described component A, component B, component C is 0.5: 1:12, wherein, the component A is the water-based epoxy emulsion H100 produced by Air Products (China) Investment Co., Ltd.; in parts by weight, the component B consists of 3 parts of water, 3 parts of curing agent and 0.01 part defoaming agent, the curing agent is a water-based epoxy curing agent, the water-based epoxy curing agent can be the 5B type curing agent produced by Shanghai Hanzhong Chemical Co., Ltd., and the defoaming agent is a powder defoaming agent. In the embodiment, a special defoamer Q809 (produced by Air Chemical Products (China) Investment Co., Ltd.) is adopted for a water-based epoxy system, which has a good defoaming effect and has good compatibility with the system; the component C It consists of 30 ...

Embodiment 2

[0041] The present embodiment provides a kind of water-based epoxy composite cement mortar material, and described material is made up of component A, component B and component C, and the mass ratio of described component A, component B, component C is 1.5: 3:18, wherein, the component A is the water-based epoxy emulsion H100 produced by Air Products (China) Investment Co., Ltd.; in parts by weight, the component B consists of 10 parts of water, 10 parts of curing agent and 0.1 Part defoamer composition, described curing agent is water-based epoxy curing agent, and described water-based epoxy curing agent can be the LJ830 curing agent produced by Shanghai Lvjia Water-based Coatings Co., Ltd., and described defoaming agent is powder defoamer, In this embodiment, a special defoamer Q809 (produced by Air Products (China) Investment Co., Ltd.) for waterborne epoxy system is adopted, which has good defoaming effect and has good compatibility with the system; the components C is com...

Embodiment 3

[0052] The present embodiment provides a kind of water-based epoxy composite cement mortar material, and described material is made up of component A, component B and component C, and the mass ratio of described component A, component B, component C is 1: 2:15, wherein, the component A is the water-based epoxy emulsion H100 produced by Air Products (China) Investment Co., Ltd.; in parts by weight, the component B consists of 6 parts of water, 6 parts of curing agent and 0.05 1 part defoamer composition, described curing agent is water-based epoxy curing agent, and described water-based epoxy curing agent can be the 721 model curing agent that U.S. Air Chemicals produces, and described defoaming agent is powder defoamer, present embodiment A special defoamer Q809 (produced by Air Chemical Products (China) Investment Co., Ltd.) is adopted in the water-based epoxy system, which has a good defoaming effect and has good compatibility with the system; the component C consists of 45 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com