Pd-containing plating solution and uses thereof

A technology of electroplating solution and content, which is applied in the field of palladium or palladium alloy film, can solve the problems of inability to obtain a dense and defect-free palladium or palladium alloy film coating, and inability to purify and purify components by assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

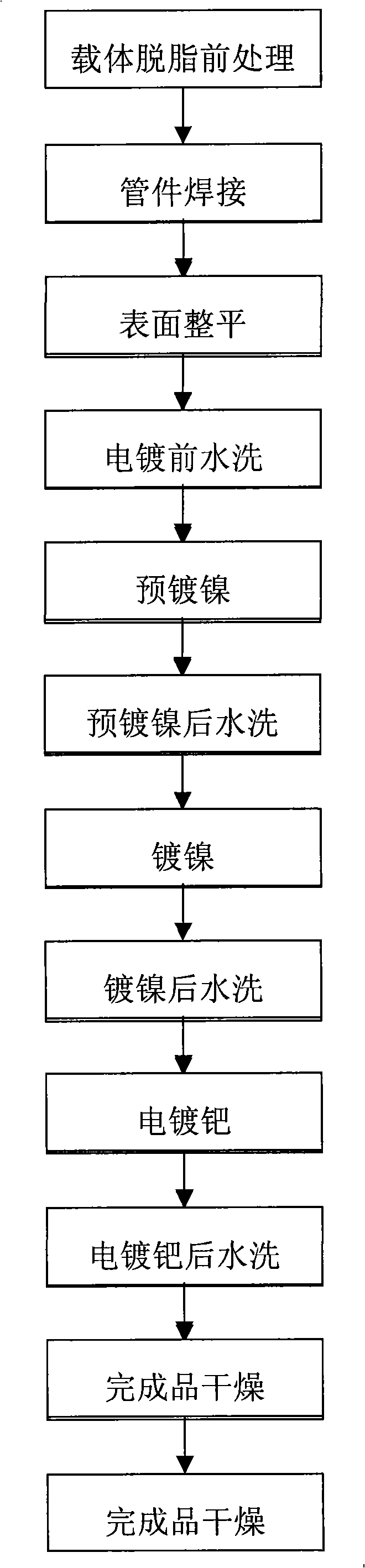

[0042] Example 1 (palladium sulfate electroplating solution system)

[0043] A. Pretreatment of porous stainless steel carrier

[0044] After cleaning the porous stainless steel pipe with toluene and acetone and degreasing it, sawing it to a length of 15 cm and erecting it with an ordinary metal pipe on an automatic rotary welding machine, injecting 8 ml / min of argon gas into the pipe, and using argon welding to form electroplated palladium The carrier required for the membrane. The welded carrier is mechanically polished with No. 600 sandpaper to level the porous stainless steel carrier and its welding points with ordinary pipes. After mechanical polishing, it is washed with ultrasonic water and dried in an oven at 150 degrees Celsius. At this time, the helium gas of 1 absolute atmospheric pressure is used to test the flow rate of the gas passing from the inside to the outside of the carrier, and the value is about 20 liters / minute.

[0045] B. Electroplating of media layer...

example 2

[0055] Example 2 (carrier speed test)

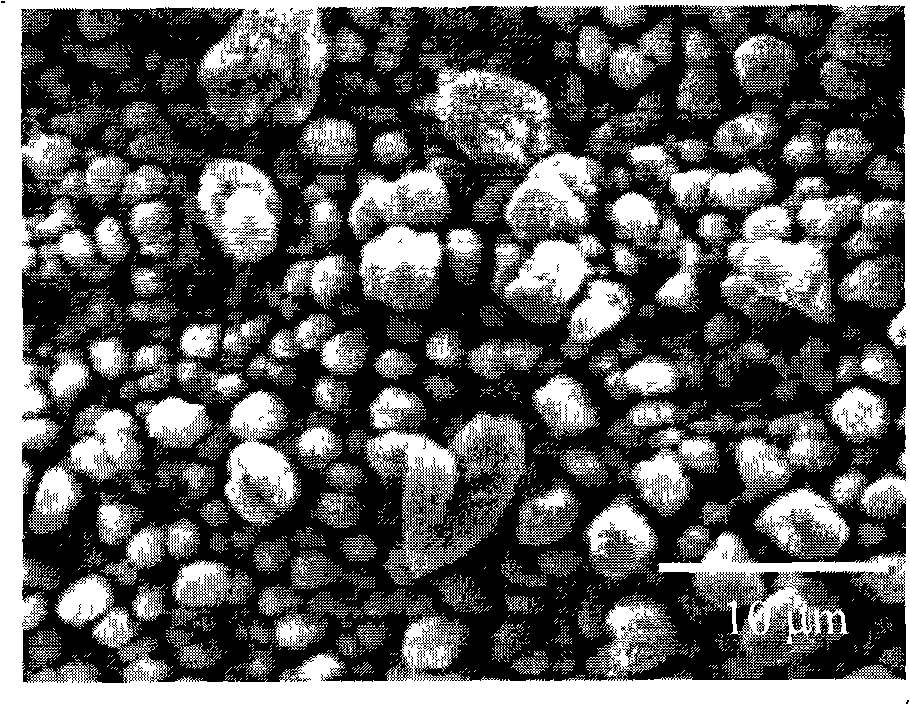

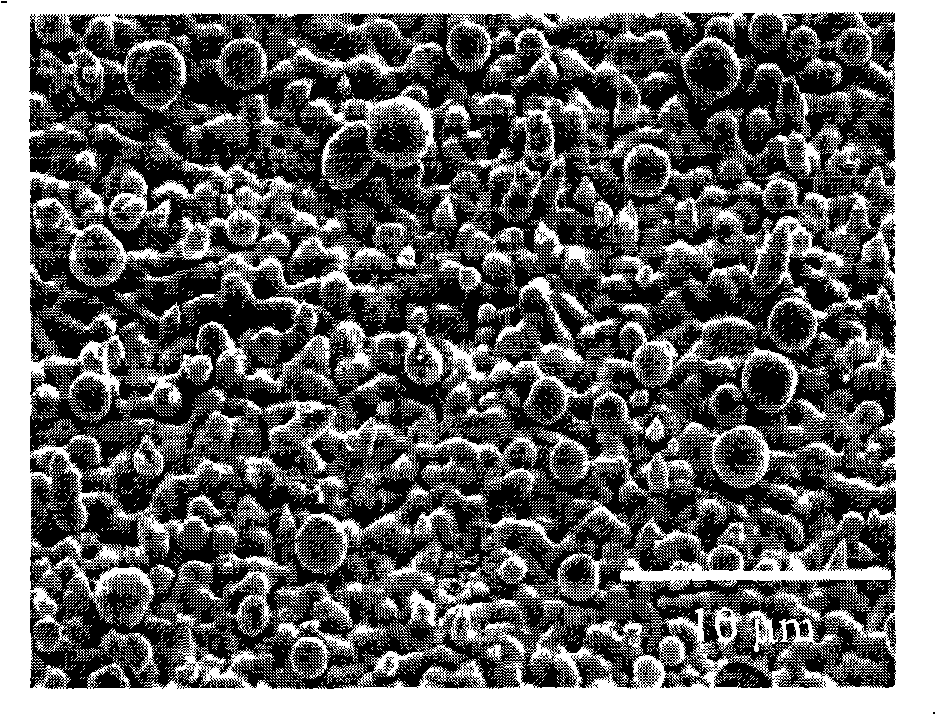

[0056] Repeat the operating conditions and steps from A to C in Example 1, but set the current density of electroplating palladium to be 1A / dm 2 , and palladium electroplating was performed at the carrier rotation speeds of 10rpm, 50rpm, 100rpm, 200rpm and 500rpm. After the palladium film was prepared, the structure of the obtained palladium film was observed with a scanning electron microscope (SEM). Fig. 2 shows the SEM images of palladium membranes obtained under the carrier rotation speeds of 10rpm (A), 50rpm (B), 100rpm (C), 200rpm (D) and 500rpm (E) respectively. It can be found that under the same density conditions, the high A relatively dense palladium film can be produced at the carrier rotation speed.

example 3

[0057] Example 3 (palladium chloride electroplating solution system)

[0058] Carry out the electroplating of palladium film with the same step as A to C in the example 1, but adopt the plating solution composition and electroplating parameter as shown in table 4.

[0059] Table 4

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com