Method for preparing colourful complex leather material

A manufacturing method and leather technology, which are applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of inability to increase the number of images and monotonous appearance of leather, achieve firm ink, avoid contamination, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

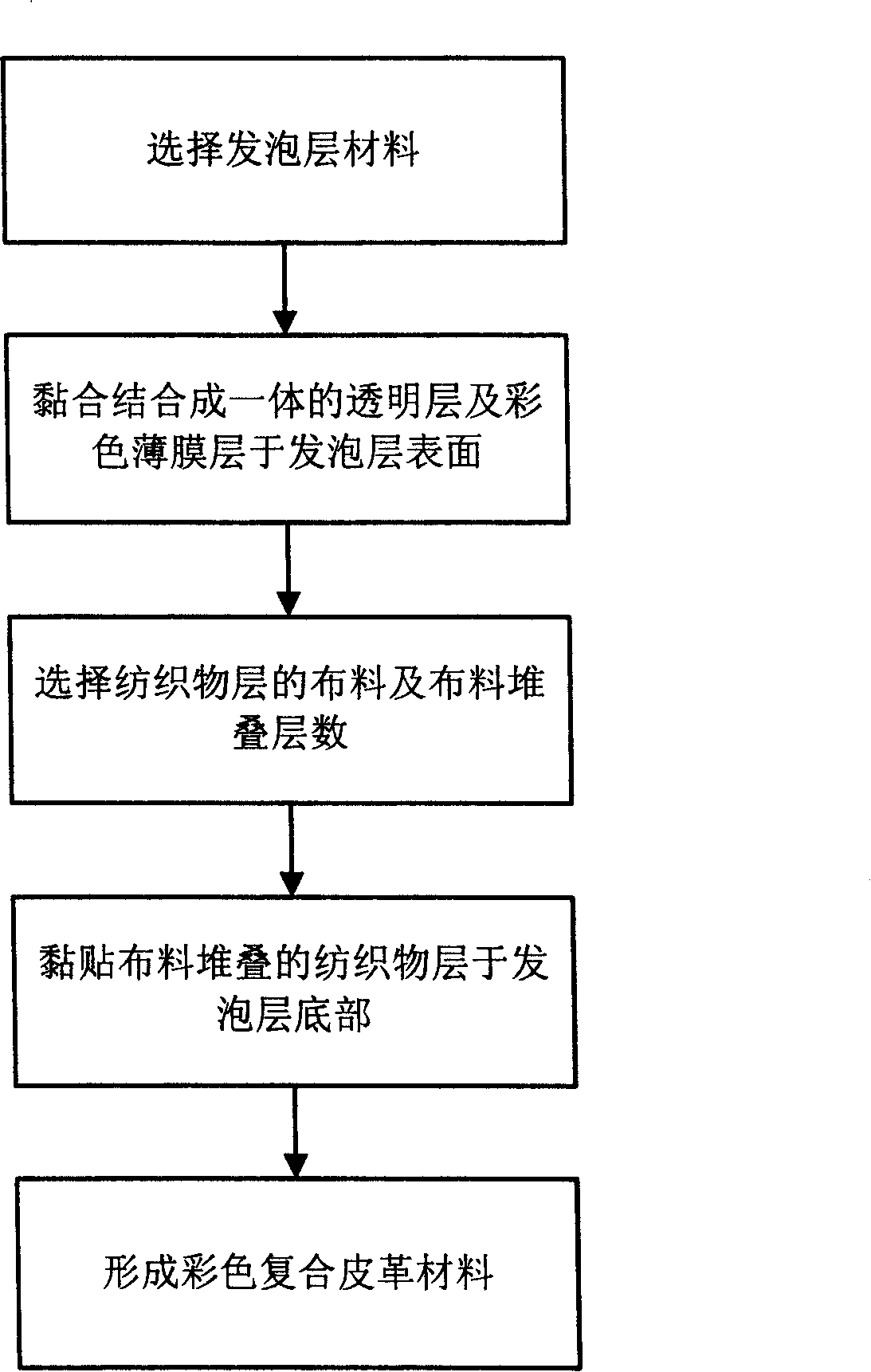

[0036] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

[0037] The manufacturing method of the colored composite leather material of the present invention adopts a preferred and feasible embodiment, which is described in detail in conjunction with the drawings, so as to increase the understanding of the present invention;

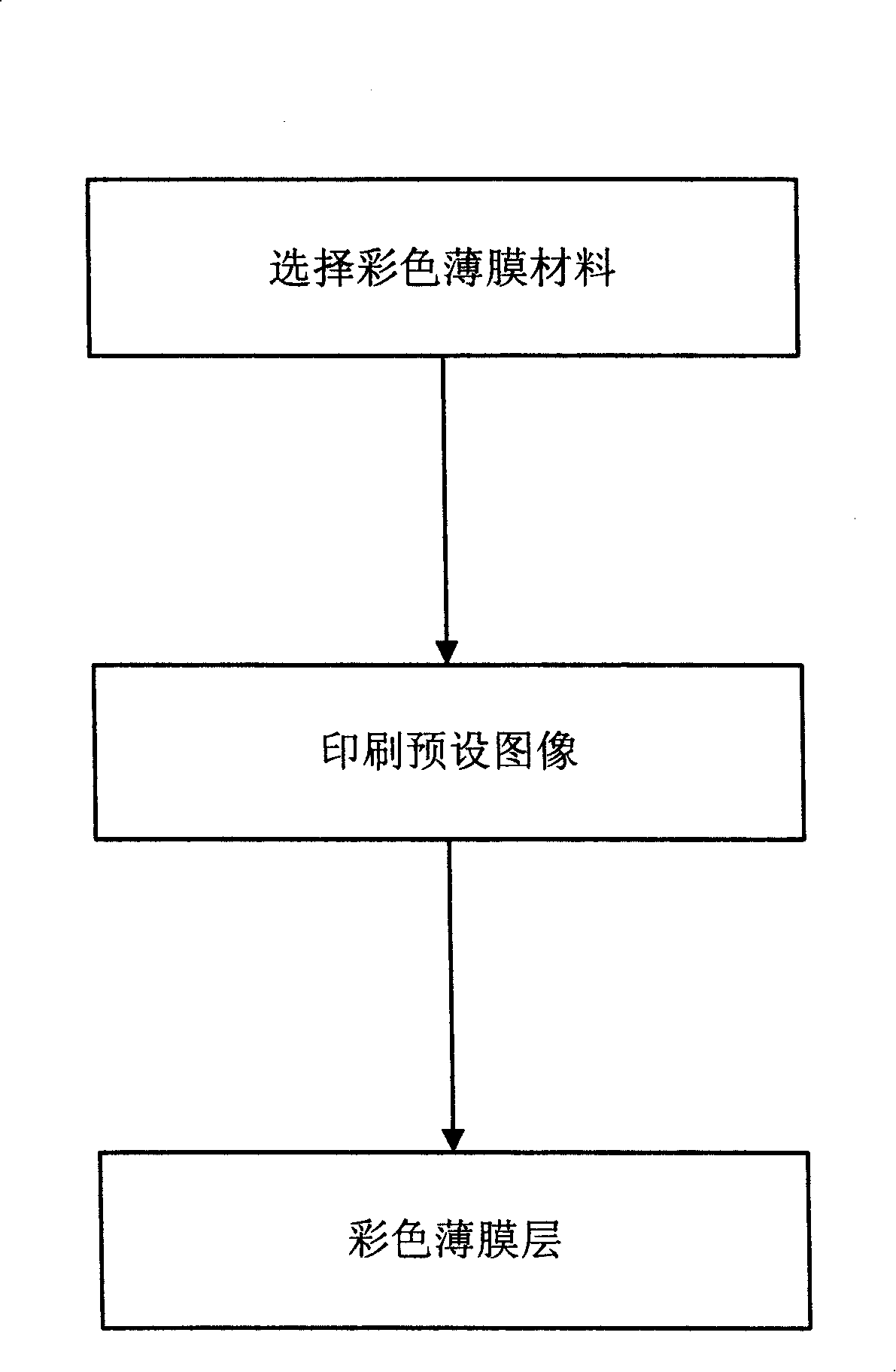

[0038] see figure 1 The flow chart for making the color film of the present invention, which first selects the porous film material, and forms the color film through printing. The color film printing referred to here especially refers to mass printing that can use automated printing equipment.

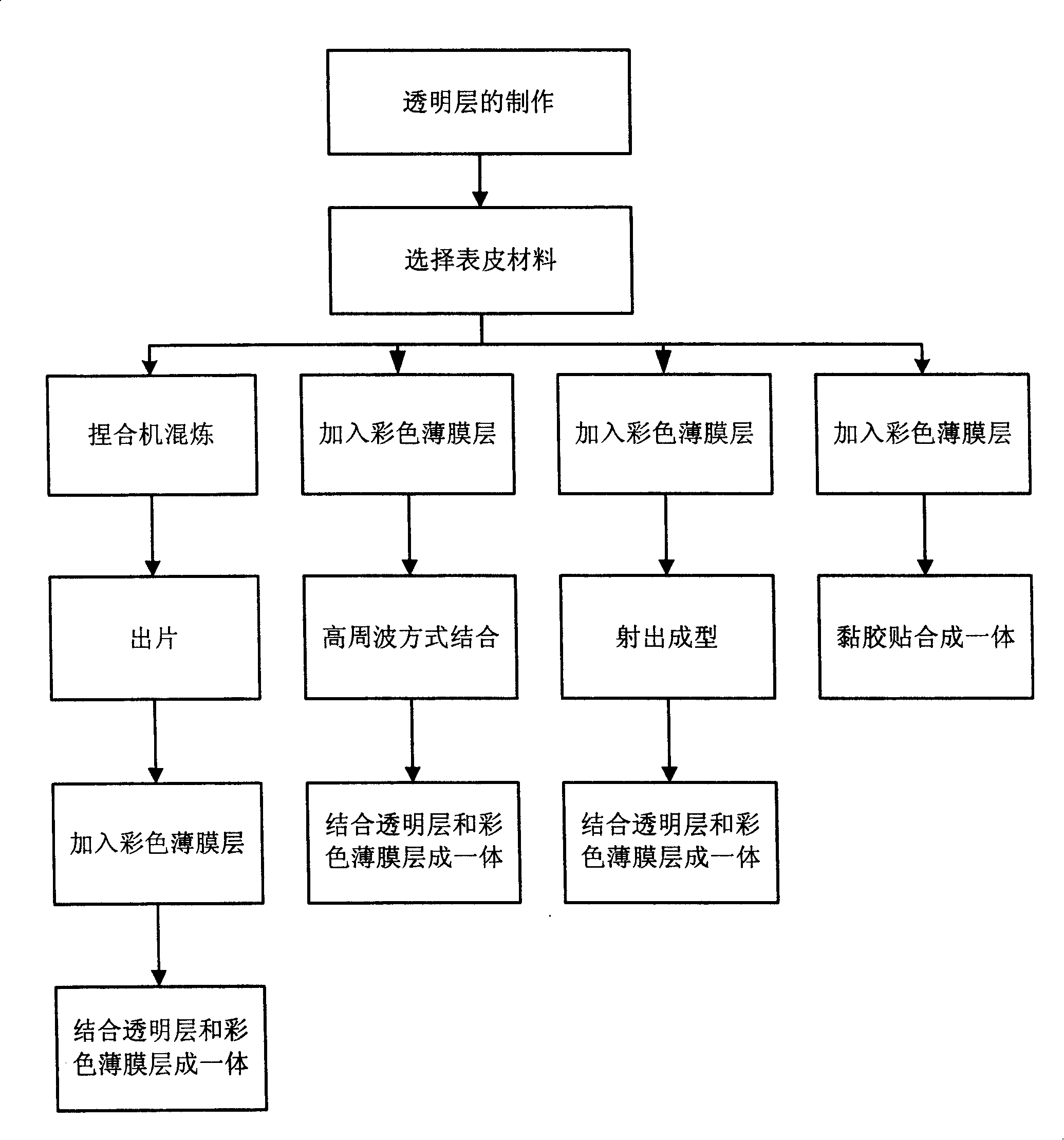

[0039] see again figure 2, is a flow chart of the compounding of the color film and the transparent layer 10 of the present invention. The compounding method has different methods due to different materials. For example, the first compounding method is injection molding, and the printed color film layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com