Method for manufacturing spectacle frame made of two materials and spectacle frame made by same

A spectacle frame and material technology, applied in glasses/goggles, technology for producing decorative surface effects, decorative art, etc., can solve problems such as difficult realization and difficult source of raw materials, and achieve simple processing, high heat resistance, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

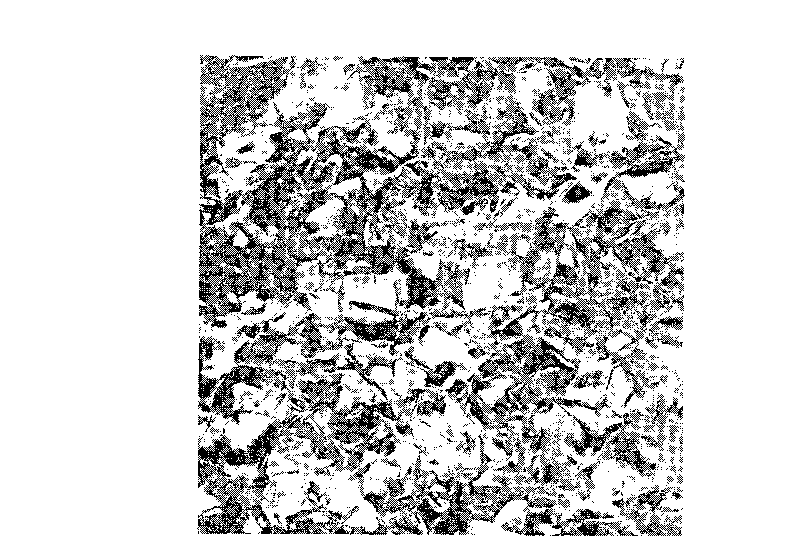

[0030] The present invention produces gorgeous and high-quality spectacle frames without peeling off by adhering polyamide injection-molded spectacle frames of thermoplastic engineering plastics with strong prototyping and acetate three-dimensional pattern paper. The specific manufacturing method is as follows: image 3 as shown,

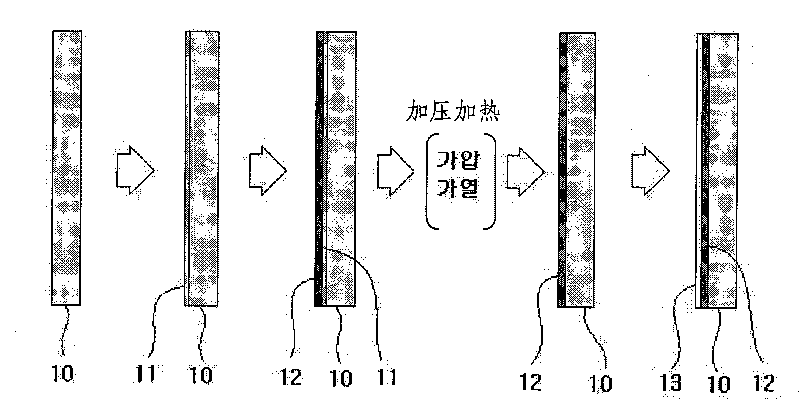

[0031] Step 1, the production of acetate three-dimensional pattern paper, such as figure 1 as shown,

[0032] 11) Make many transparent colored blank resin papers by mixing acetate resin with pigments, pearls, and abrasive paste;

[0033] 12) Then add a lot of pigments on the transparent color blank resin paper to make a monochrome (black, red, blue, etc.) film or multicolor film with a thickness of several millimeters or tens of millimeters. This color adding step can be colored on one side , if col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com