Disk loader

A loading device and disk technology, which is applied in the recording of information on the disk, magnetic recording, instruments, etc., can solve the problems of excessive protrusion and unstable maintenance, and achieve the effect of avoiding disk contamination and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The best way to practice the invention

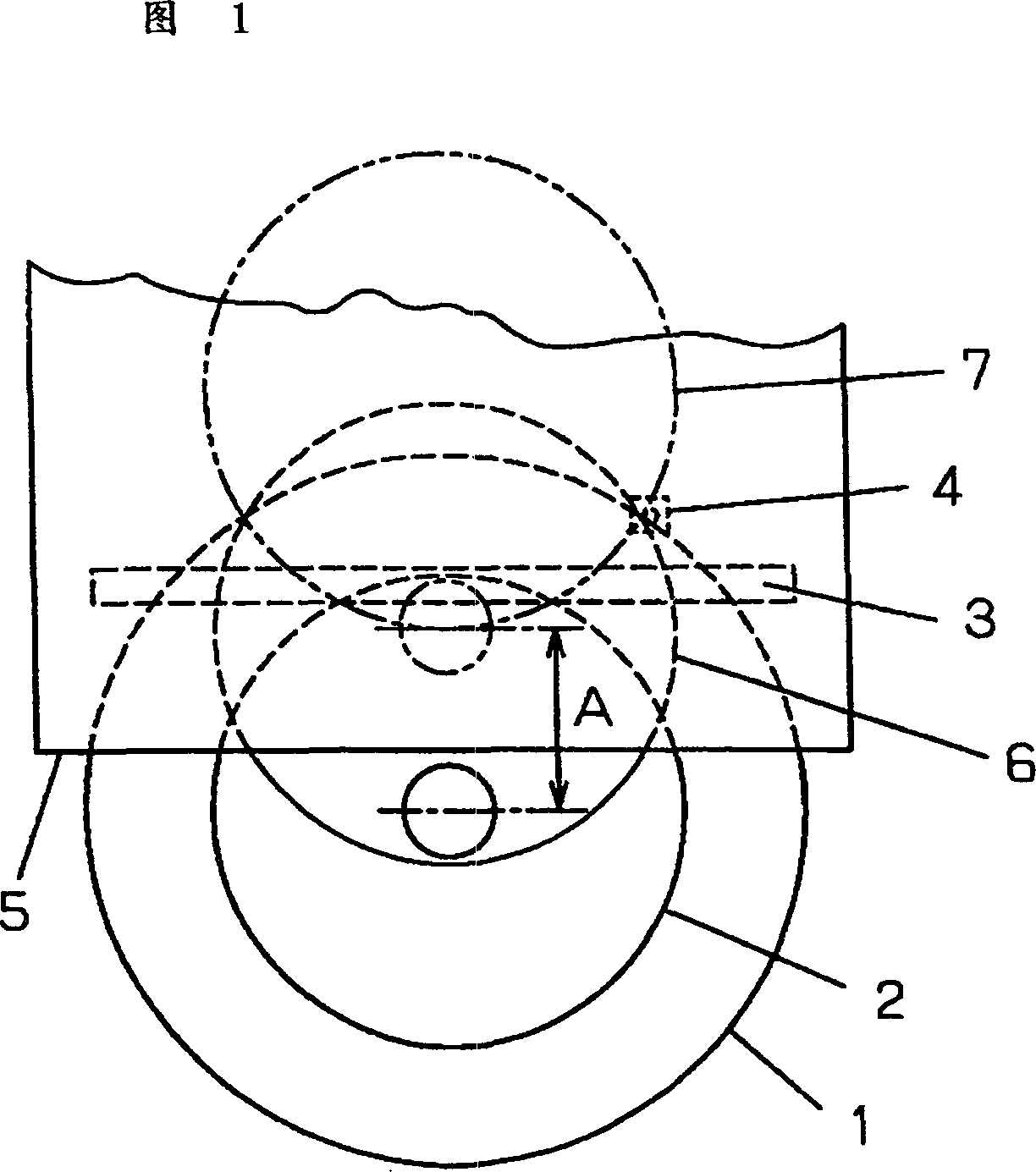

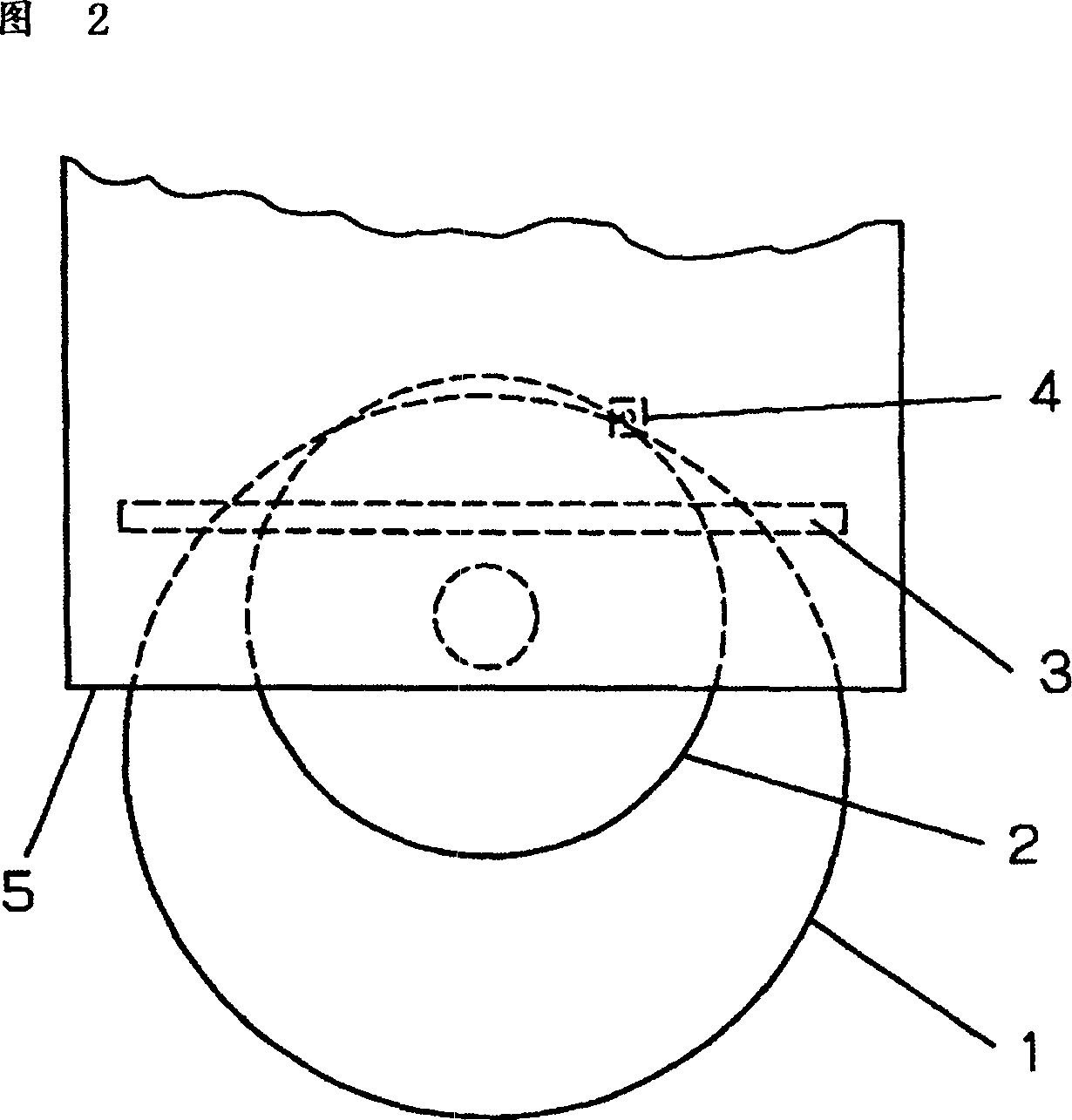

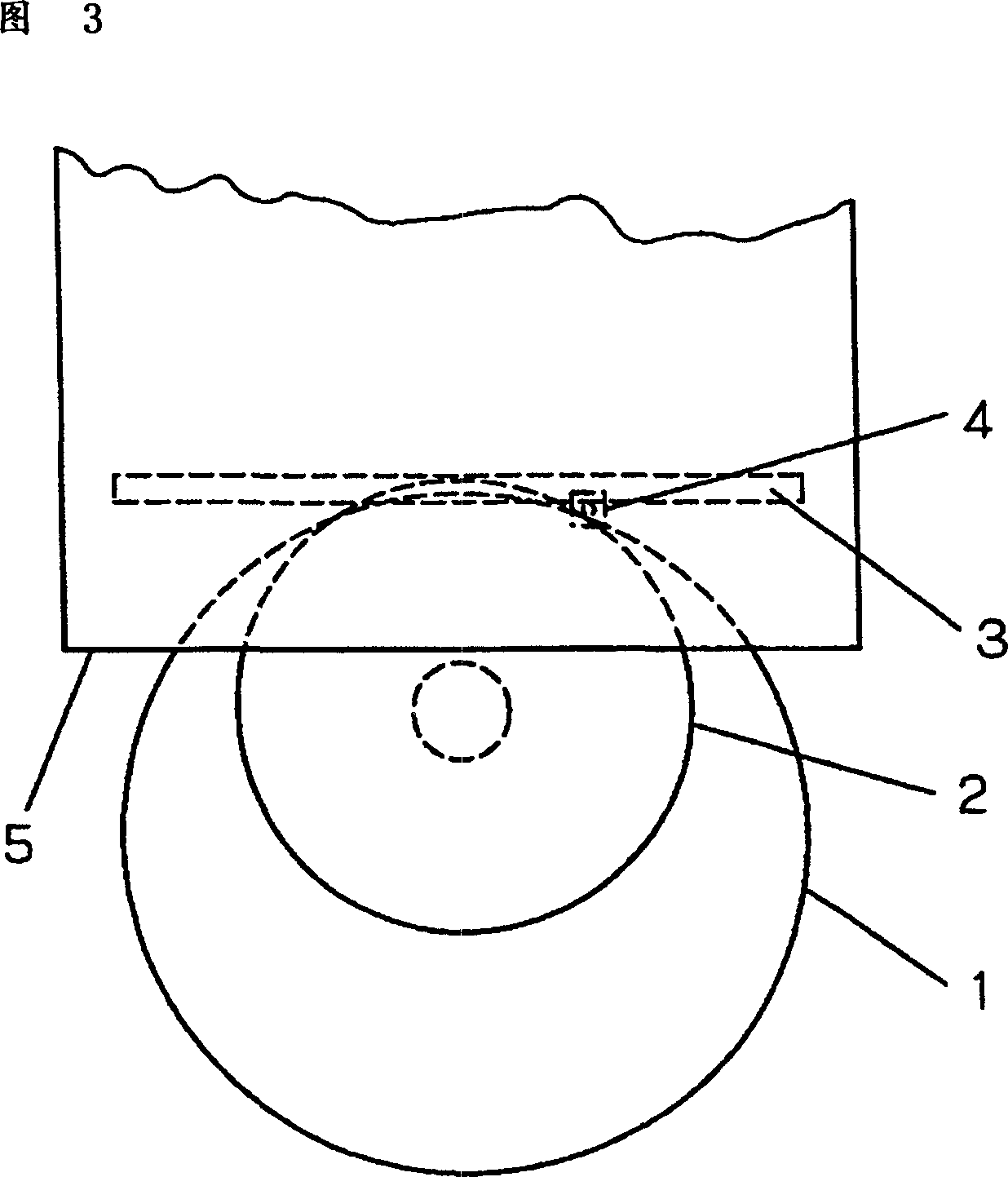

[0011] Fig. 1 shows a disk loading device of an embodiment of the present invention. The same parts as in Fig. 2 are given the same symbols. FIG. 1 shows a position 6 where the small-diameter magnetic disk 2 is ejected and a pass detection, and a position 7 where the small-diameter magnetic disk 2 is set on a turntable (not shown). In this device, when withdrawing from the large-diameter magnetic disk 1, when the passage of the large-diameter magnetic disk 1 is detected by the magnetic disk passing detection switch 4, the driving of the roller 3 will be stopped immediately, and the center hole will be used in the state where the central hole protrudes from the device main body 5. The disk stops and keeps it. And when withdrawing from the small-diameter disk 2, when the passing of the disk 2 is detected, the roller 3 is driven for a certain period of time instead of stopping immediately, and the driving of the roller 3 is stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com