Two-stage backflow drying type high-speed printing device

A printing device, drying technology, applied in printing, printing presses, general parts of printing machinery, etc., can solve problems such as affecting the quality and efficiency of printing operations, inability to dry ink quickly, adverse effects of printing operations, etc., and achieve energy saving rate. , The effect of avoiding ink contamination and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

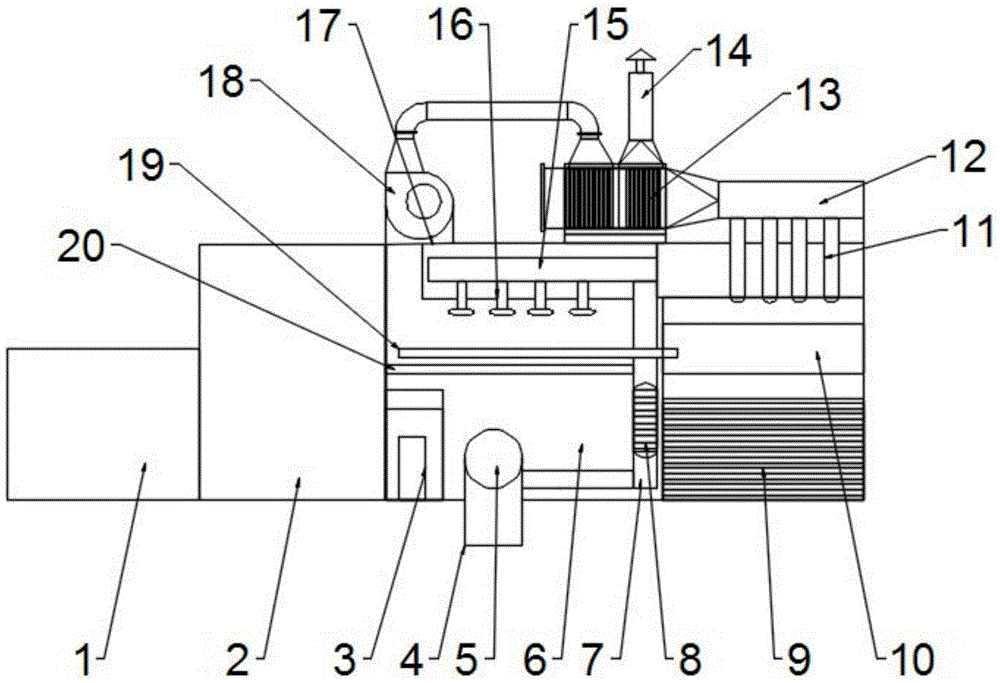

[0015] see figure 1 , a two-stage reflux drying type fast printing device, including a body 2 arranged on a mounting frame, a paper feeding mechanism 1 is provided on the left side of the body 2, a paper delivery mechanism 10 is provided on the right side of the body 2, and a There are a paper positioning mechanism, a paper delivery mechanism, a printing mechanism, an ink feeding mechanism and a control mechanism, and each mechanism in the machine body 2 performs normal printing operations;

[0016] A drying chamber 6 is provided between the machine body 2 and the delivery mechanism 8 , and a horizontal partition 20 is provided in the middle of the drying chamber 6 . The upper surface of the partition 20 is provided with a conveyor belt for conveying the paper 19 ; And the driving power supply 13 for the blower fan 5, the lower end of the drying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com