An electromagnetic forming device and a method for preparing fiber-reinforced metal matrix composites using the device

A fiber-reinforced and composite material technology is applied in the field of electromagnetic forming devices and the preparation of fiber-reinforced metal matrix composite materials by using the device, which can solve the problems of long-term pressure holding, low process and equipment costs, and low production efficiency by the hot-pressing method. , to achieve the effect of being suitable for mass production, slowing down the formation of interfacial brittle phases, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

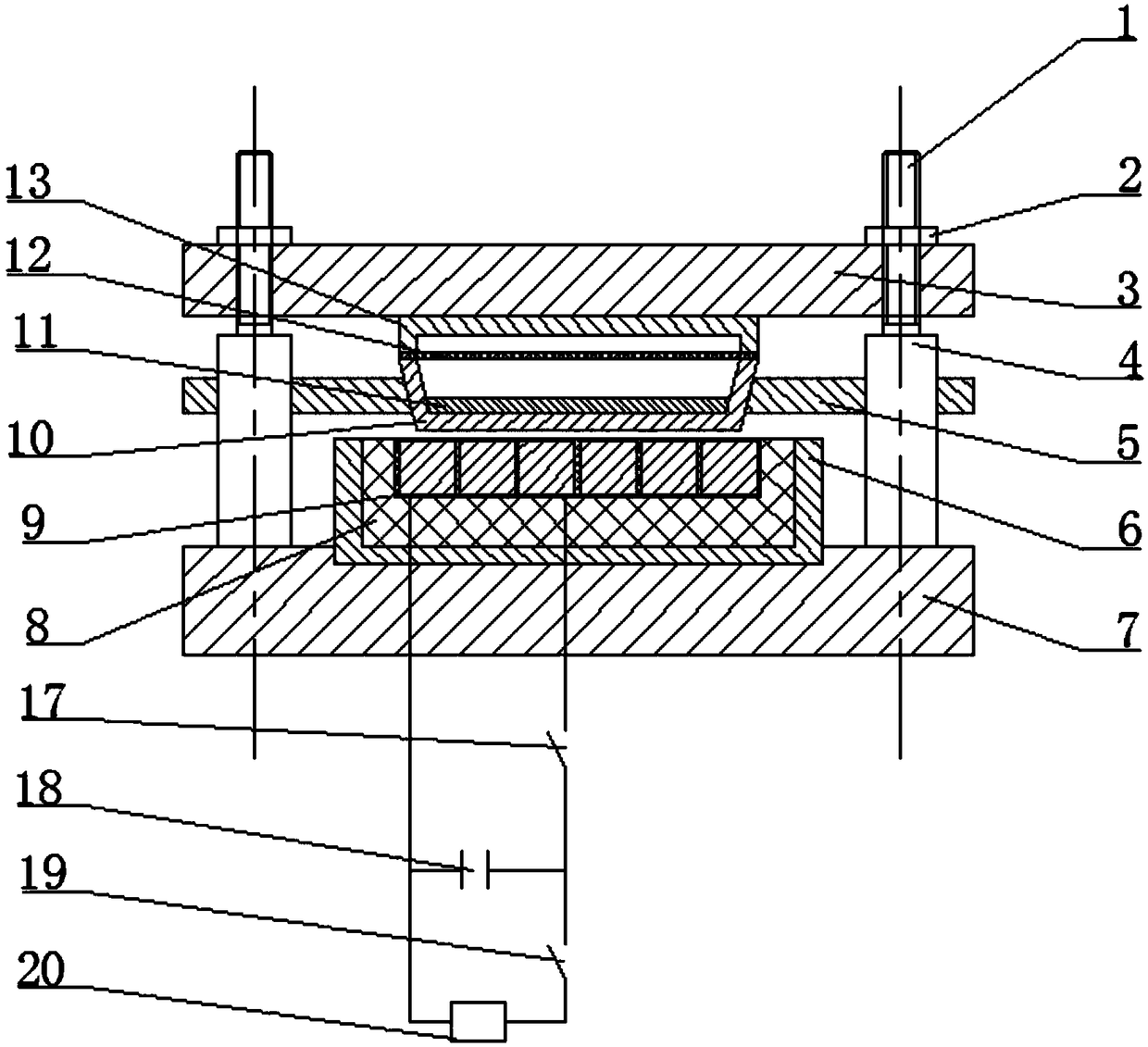

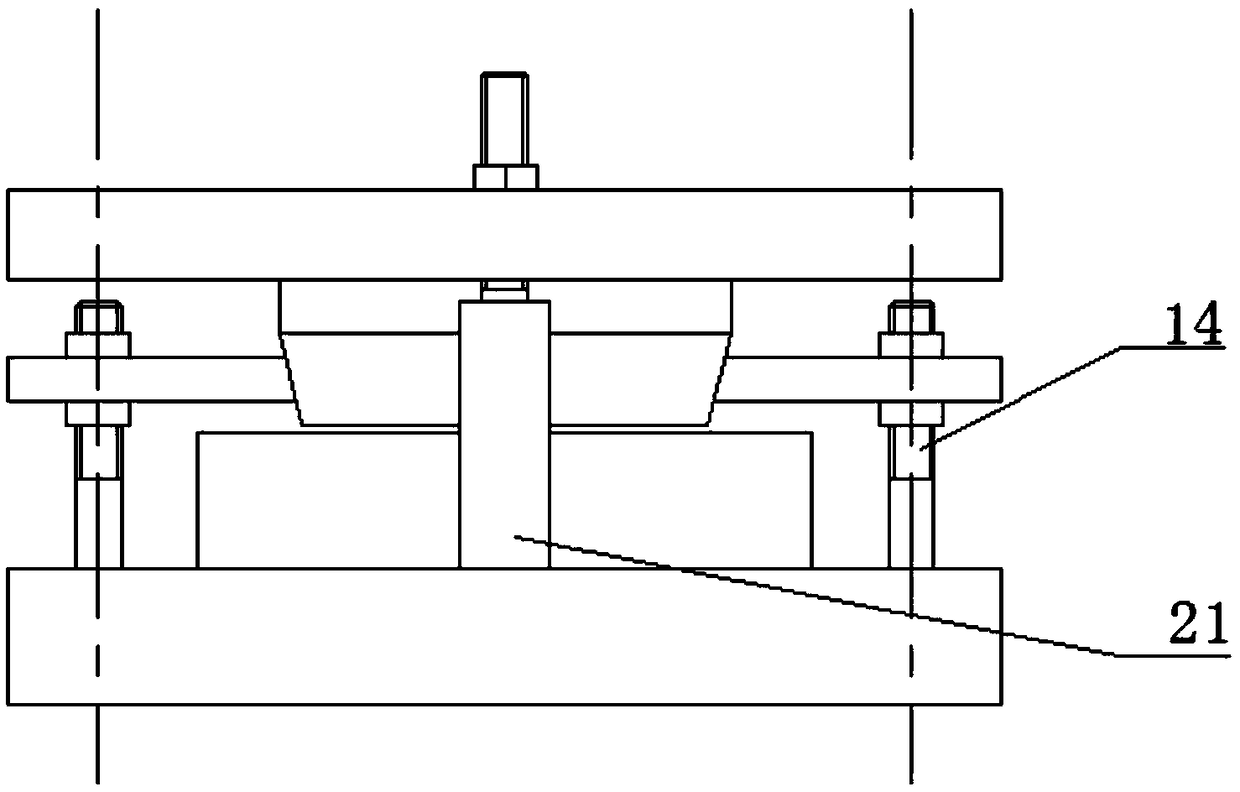

[0043] Such as figure 1 , 2 Shown is an electromagnetic pulse forming device for fiber-reinforced metal matrix composites in this embodiment. The electromagnetic forming device includes a lower platen 7, a coil charging and discharging device, a coil fixing device, a crucible 10, a crucible positioning device, a die 13 and a die fastening device. The lower pressing plate 7 is provided with a cylindrical groove. The coil charging and discharging device includes a discharge coil 9, a capacitor 18 connected in series with the discharge coil 9, and a power supply connected in parallel with the capacitor 18, wherein the power supply is connected in series with the charging control switch 19, and the discharge coil 9 is connected in series with the discharge control switch 17. The coil fixing device includes a concentric coil frame 8 with a cylindrical groove and a coil base 6, the discharge coil 9 is embedded and fixed in the groove of the coil frame 8, and the coil frame 8 is em...

Embodiment 2

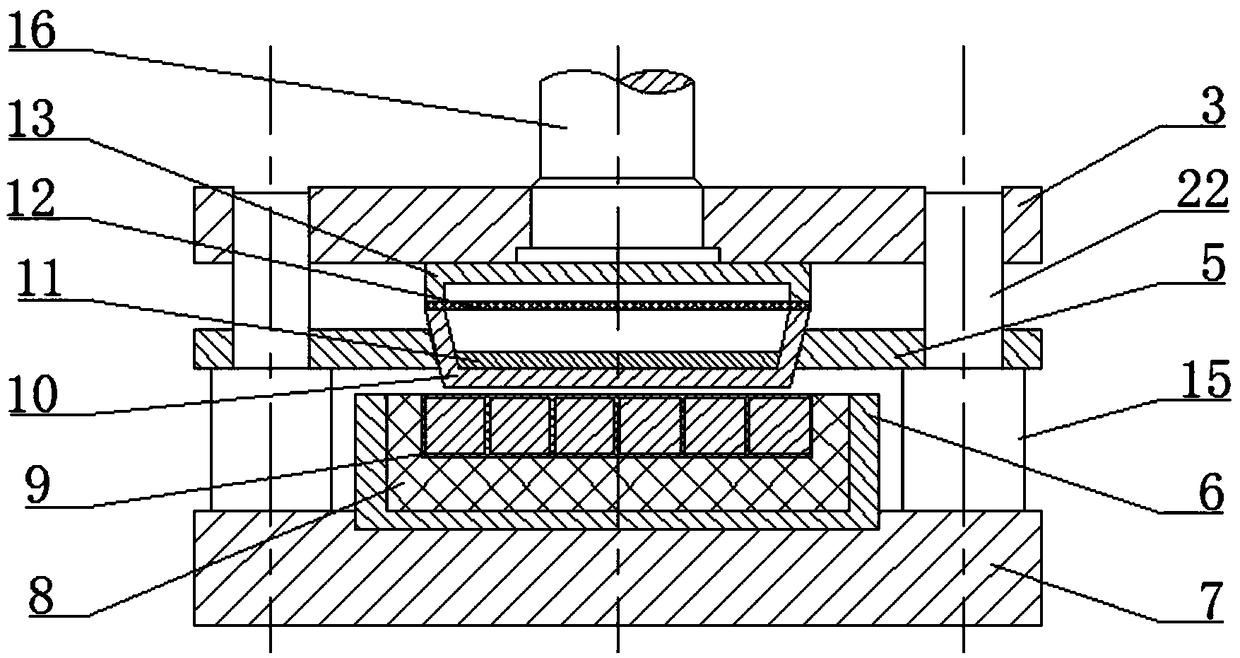

[0049] Such as image 3 Shown is an electromagnetic pulse forming device for fiber-reinforced metal matrix composites in this embodiment. The electromagnetic forming device includes a lower platen 7, a coil charging and discharging device, a coil fixing device, a crucible 10, a crucible positioning device, a die 13 and a die fastening device. The lower pressing plate 7 is provided with a cylindrical groove. The coil charging and discharging device includes a discharge coil 9, a capacitor 18 connected in series with the discharge coil 9, and a power supply connected in parallel with the capacitor 18, wherein the power supply is connected in series with the charging control switch 19, and the discharge coil 9 is connected in series with the discharge control switch 17. The coil fixing device includes a concentric coil frame 8 with a cylindrical groove and a coil base 6, the discharge coil 9 is embedded and fixed in the groove of the coil frame 8, and the coil frame 8 is embedde...

Embodiment 3

[0056] This example uses the same device as Example 1 to prepare fiber-reinforced metal matrix composites. The undisclosed technical features are the same as Example 1, except that the discharge capacitance in step 2) is 12300 μF, the discharge voltage is 640V, and the discharge energy It is 2.52kJ. The distance between the bottom of the crucible 10 and the discharge coil 9 is 3 mm. The photo of the composite material formed part obtained in this embodiment is as follows Figure 6 As shown, its thickness is 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com