Depth Gauge Calibration Detection Device

A technology for detection devices and depth gauges, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of long detection period, many detection cables, easy oil pressure pollution, etc., achieve wide detection range, reduce maintenance work, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

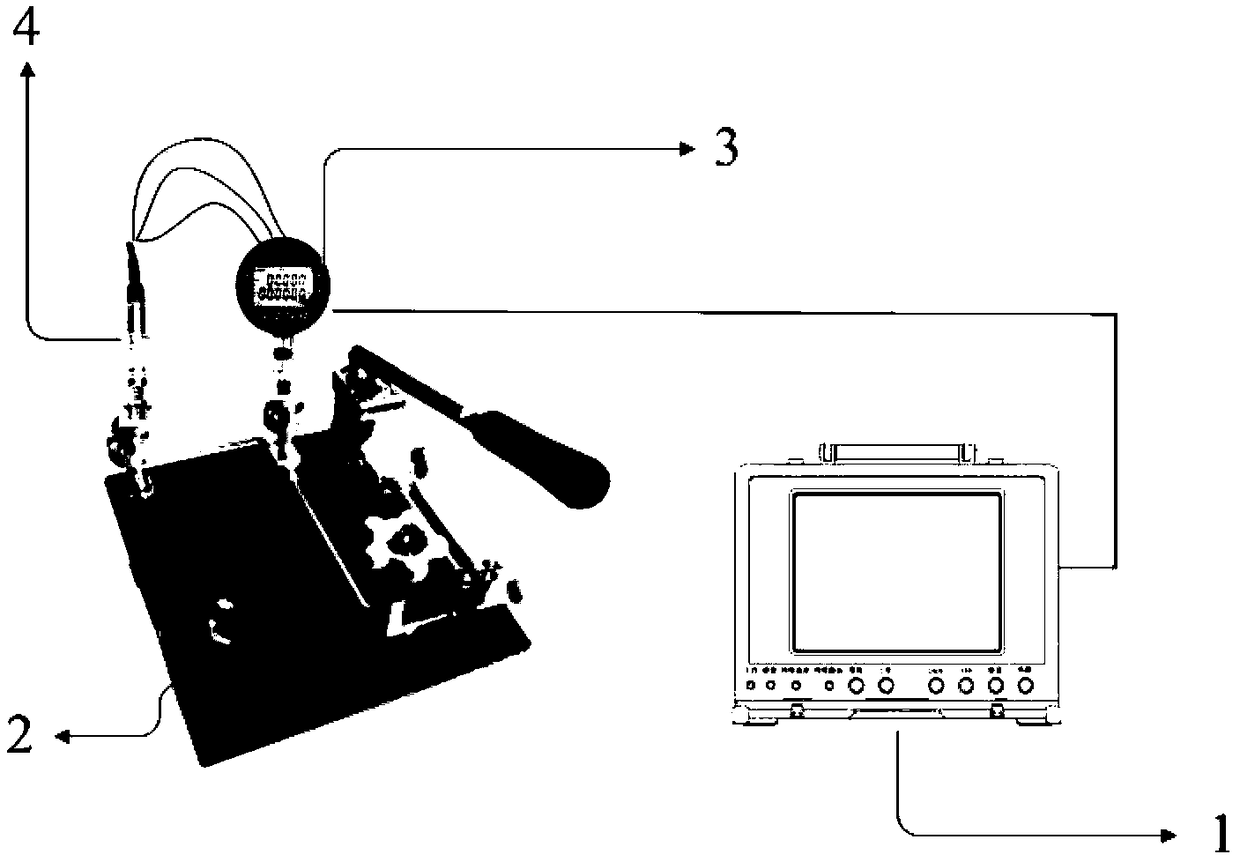

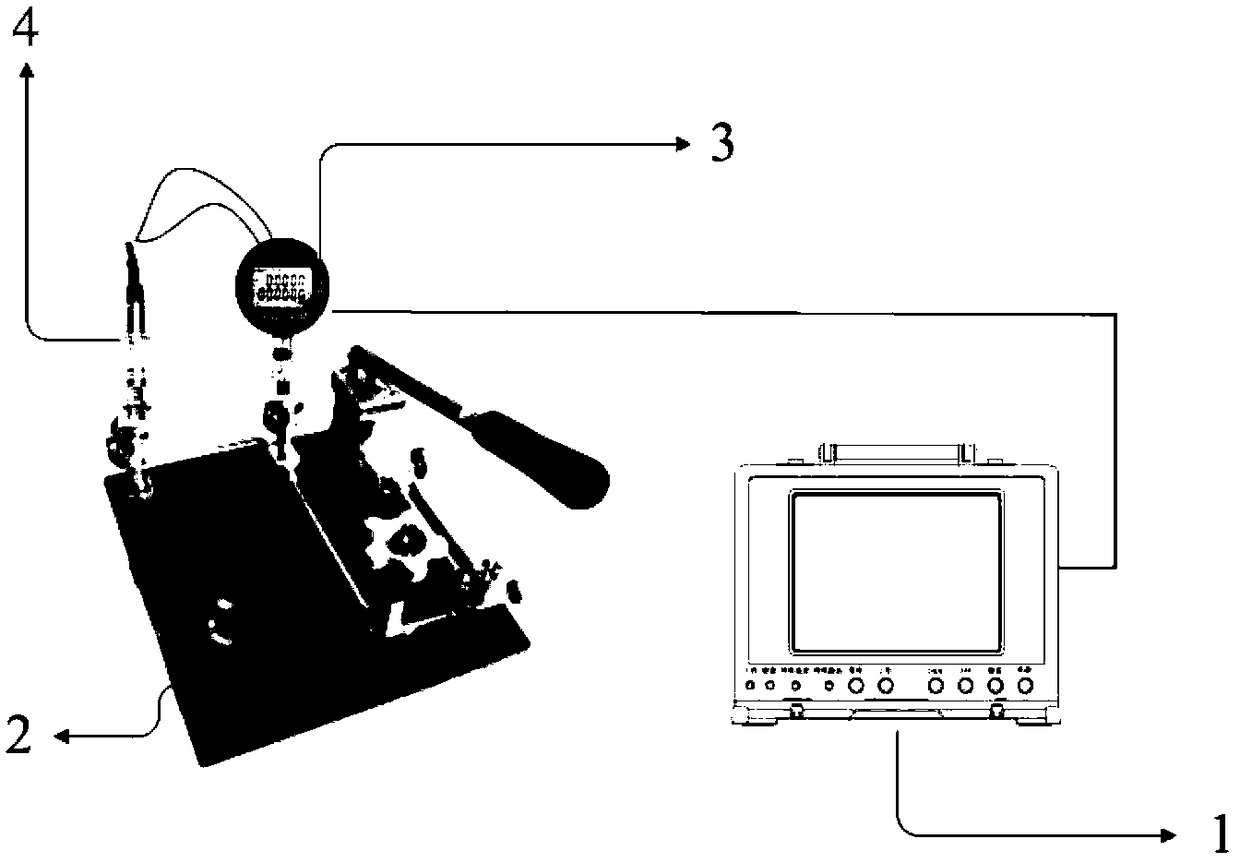

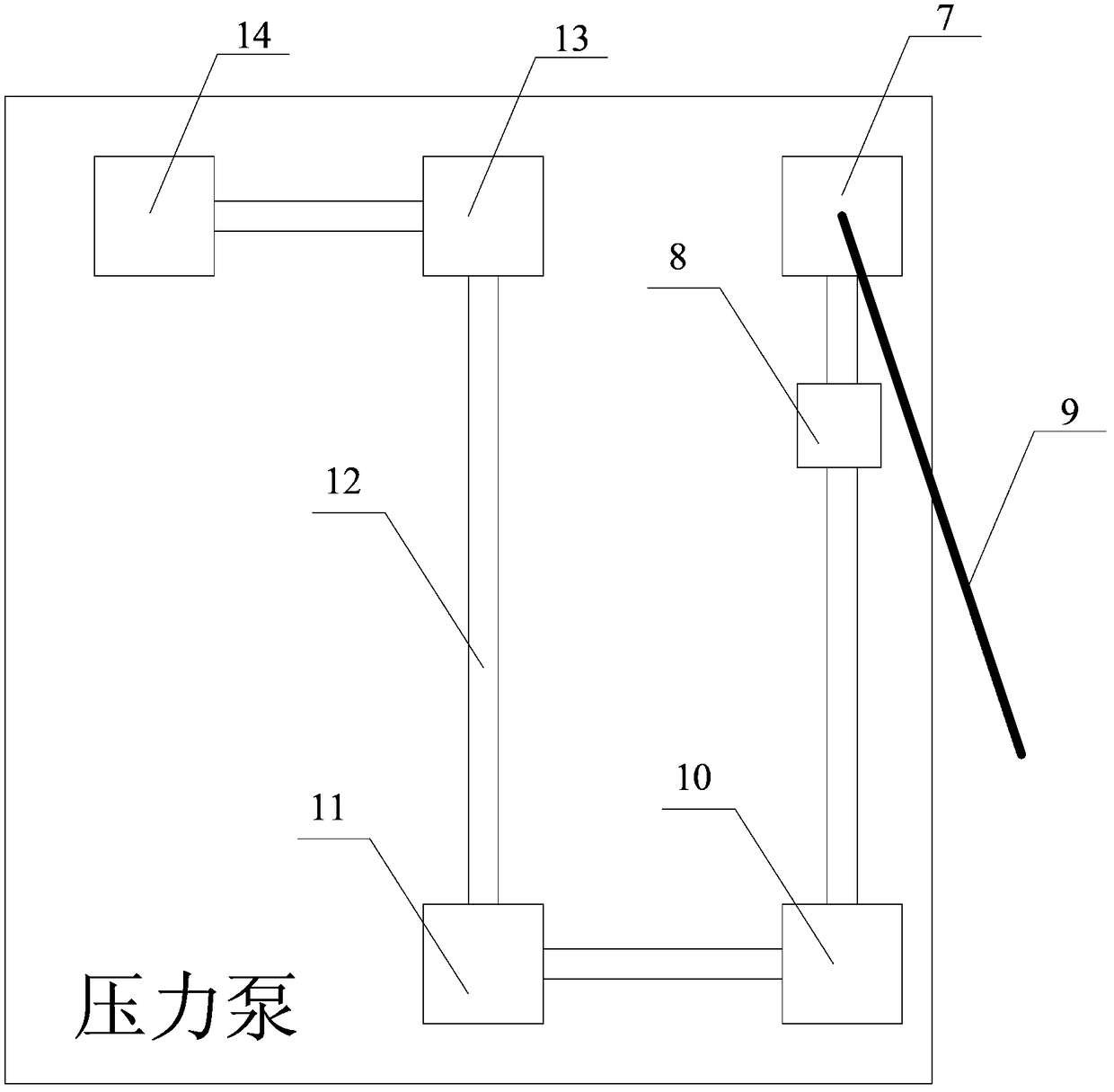

[0021] as attached figure 1 , shown in 2, is a depth gauge calibration detection device, including a computer 1, a pressure pump and a pressure calibrator 3; the pressure pump is a desktop air pressure pump, the pressure calibrator 3 is a digital pressure calibrator, and the computer 1. Put it into the chassis with a side protective cover. 5. Connect to the output end of the pressure calibrator 3 through the RS232 retrieval serial port 6. The input end of the digital pressure calibrator 3 is installed on the pressure port 13 of the pressure pump on the base plate 2. The output end of the depth gauge 4 of the test piece is connected to the detection end of the pressure calibrator 3 through a connecting line. The detection circuit; the pressure value of the pressure pump is displayed by the pressure calibrator 3 to ensure that the measured dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com