cooking components

A component and component technology, applied in the field of cooking components, can solve the problems of dirt, wear and tear of coffee machines, damage to the driving mechanism of the cooking components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

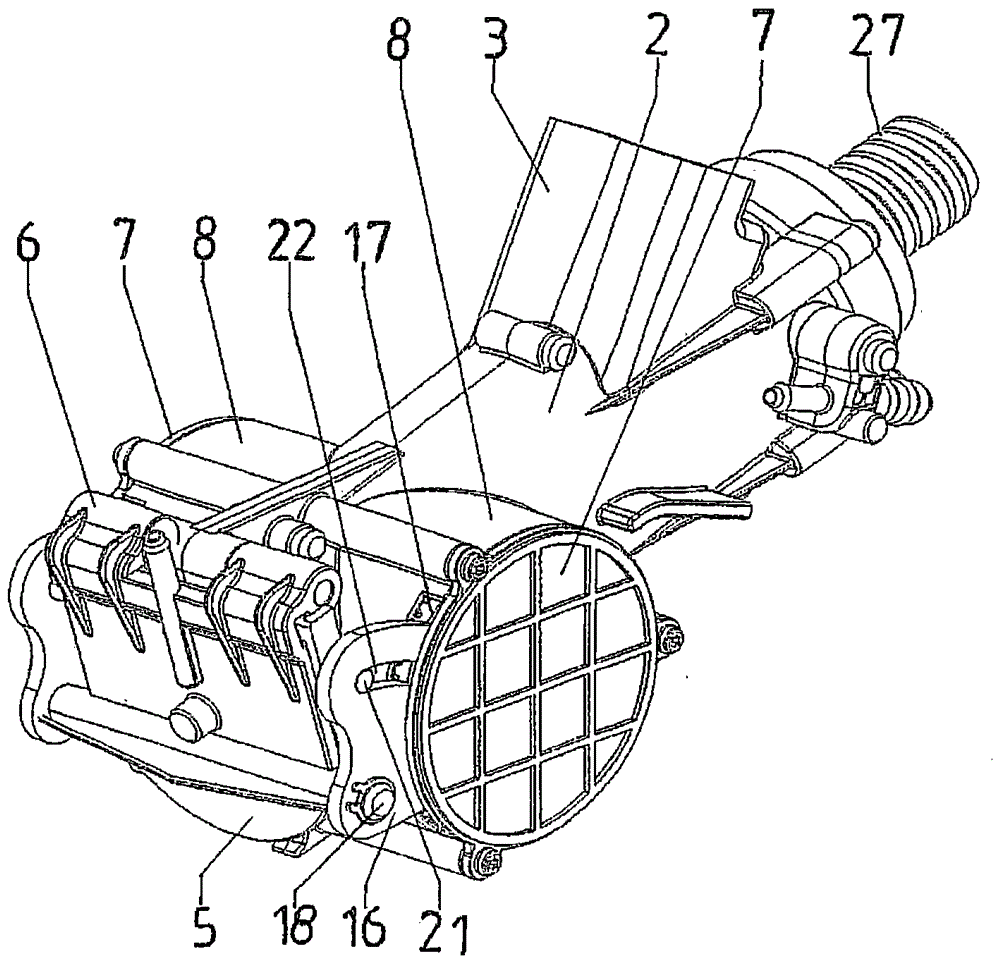

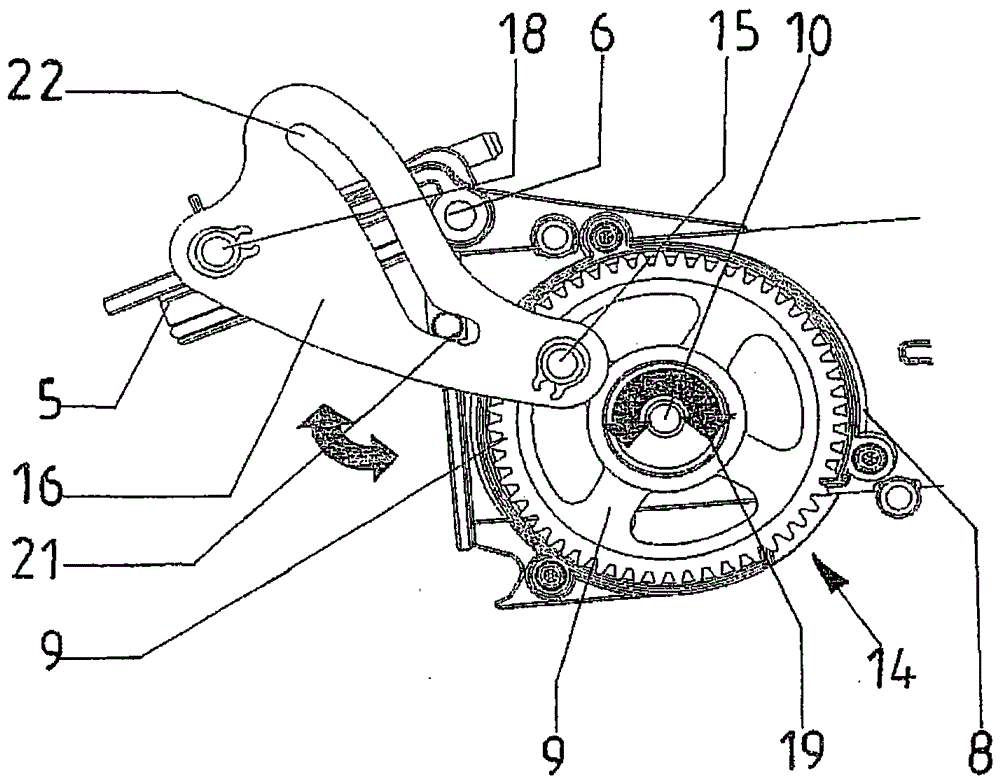

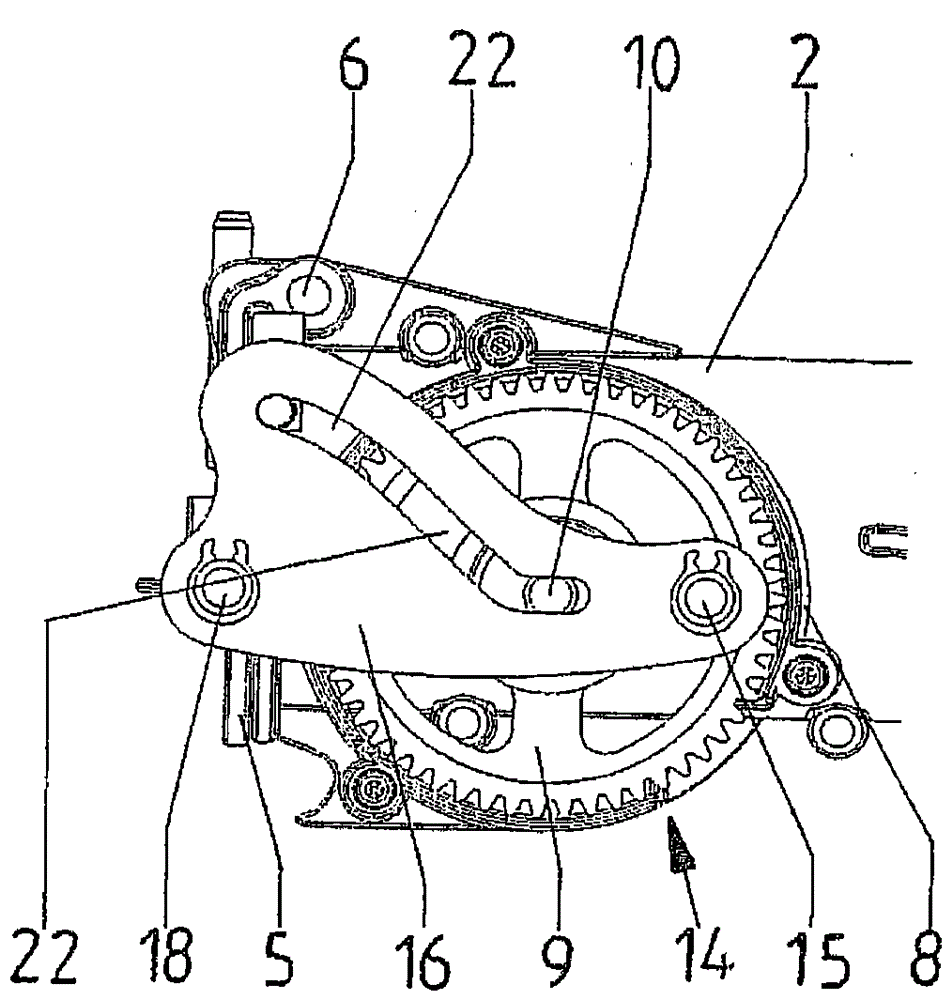

[0041] A cooking assembly and its main components are shown in the accompanying drawings. Such a brewing group is an integral part of a coffee machine and is used in particular for preparing coffee-like beverages or espresso.

[0042] The brewing group has a brewing chamber 1 for receiving ground coffee grounds. In addition, the brewing group has components for compacting the ground coffee located in the brewing chamber 1 and for draining wet ground coffee residues from the brewing chamber 1 . Connections are also provided for supplying hot water and for discharging the corresponding coffee filtrate.

[0043] The brewing chamber 1 is formed by a stationary cylinder 2 arranged immovably, which has a filling opening 3 for ground coffee on the top side near its first end. As a component for compacting the coffee grounds loaded into the brewing chamber 1, on the first end of the cylinder 2 there is provided a piston 4 which is axially displaceable by means of a first adjusting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com