Shoes

a technology for forming shoes and shoes, applied in the field of shoes, can solve the problems of improper support, inability to change, and excessive pressure on the ball of the foot, and achieve the effect of a wide range of the appearance of the heel member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

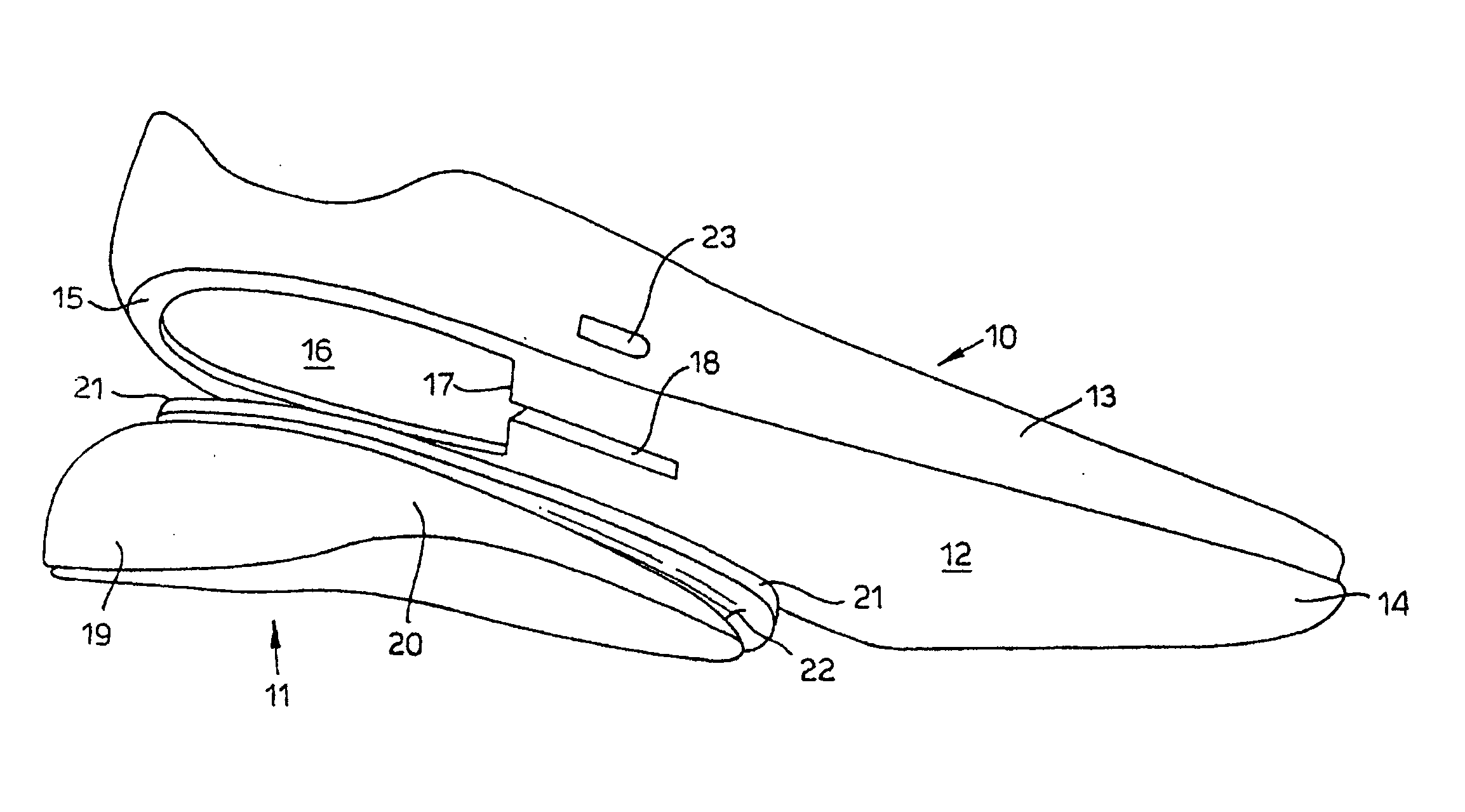

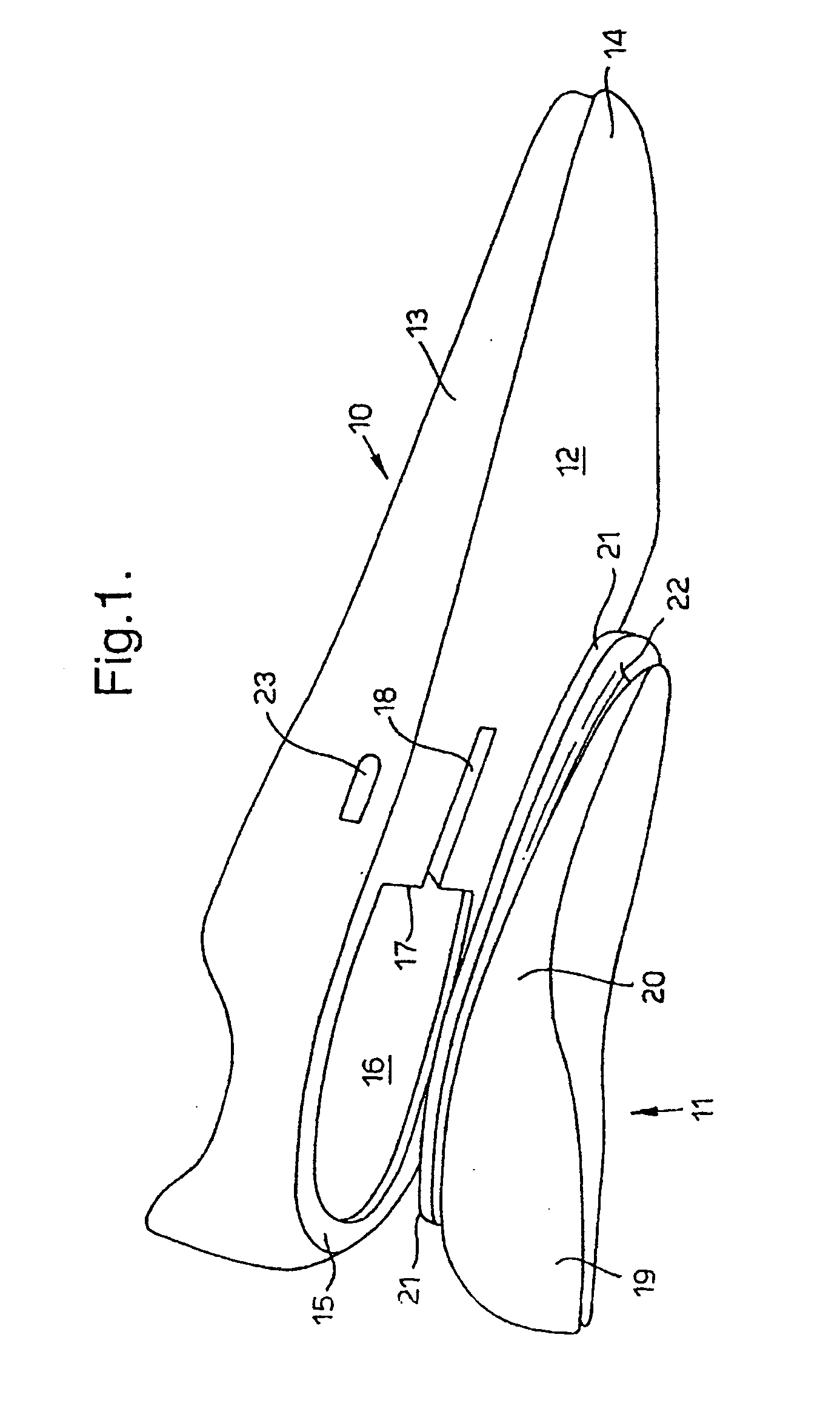

[0067] Referring first to FIG. 1, the sub-assembly for incorporation into a shoe or kit for forming a shoe is formed by a flexible member indicated generally at 10 and a heel 11. The flexible member 10 comprises a generally flat lower wall 12 surrounded by an upwardly and outwardly extending shaped side wall 13. As seen in FIG. 1, the lower wall 12 has the outline shape of the sole of a shoe with a toe end 14 and a heel end 15. The end of the lower wall 12 towards the heel end 13 is provided with an elongate D-shaped aperture 16 with a straight edge 17 of the aperture 16 towards the toe end 14. An elongate rectangular slot 18 extends through the lower wall 12 commencing at the edge 17 and extending towards the toe end 14.

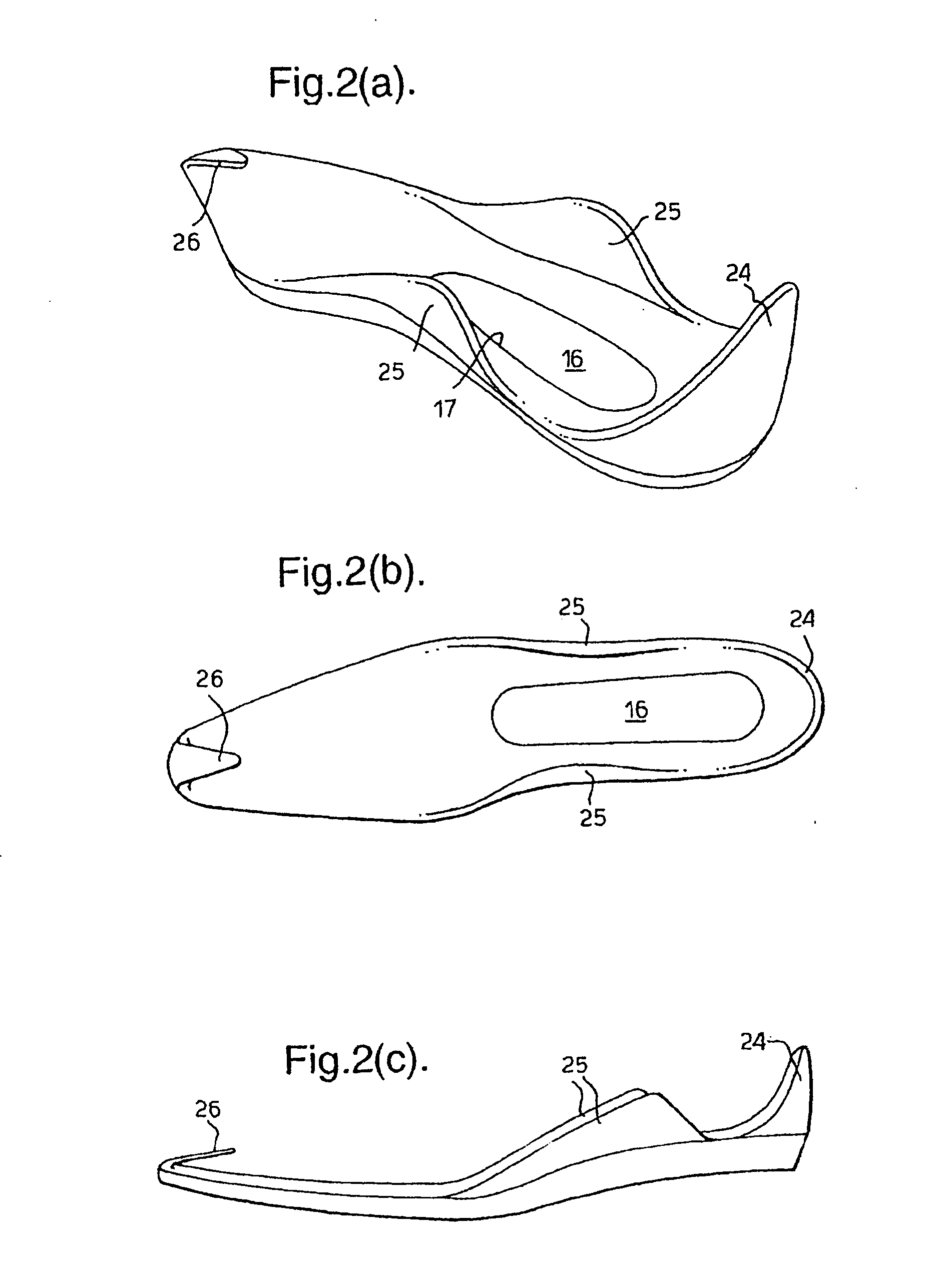

[0068] The flexible member 10 may be made from any suitable material but is preferably made from flexible plastics material such as a polyurethane material. As shown separated from the heel 11, the flexible member 10 is capable of a plurality of different configura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com