Method for manufacturing breathable shoe

a technology of breathable shoes and manufacturing methods, applied in the field of breathable shoes, can solve the problems of not being breathable, unable to apply classic methods, and preventing the provision of particularly thin soles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

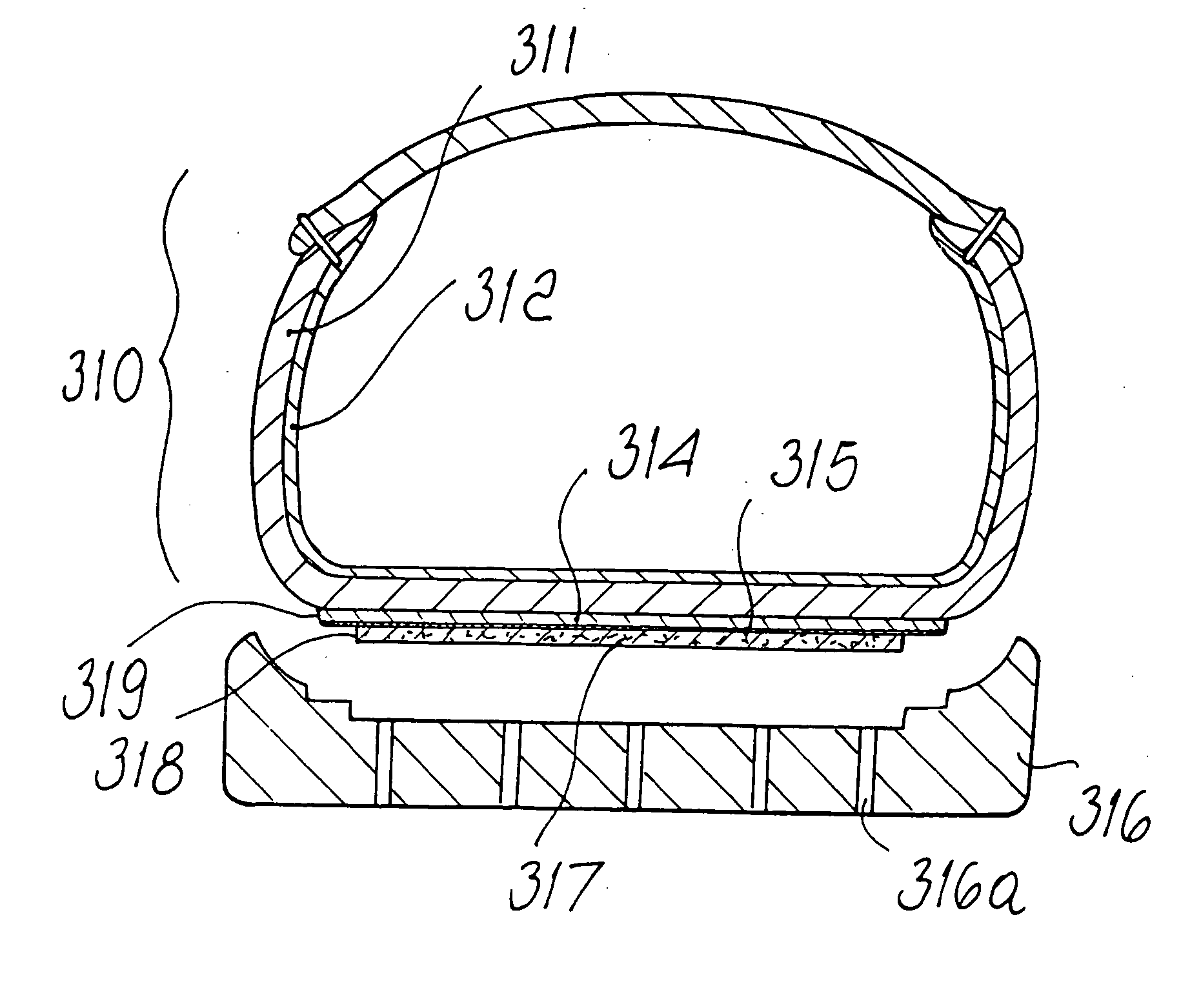

first embodiment

[0052] The shoe according to the invention, as shown by the description of this first embodiment, is entirely breathable, any non-breathable regions being limited substantially to the perimetric regions of the sole, which must in any case ensure a good seal with respect to external moisture and water.

second embodiment

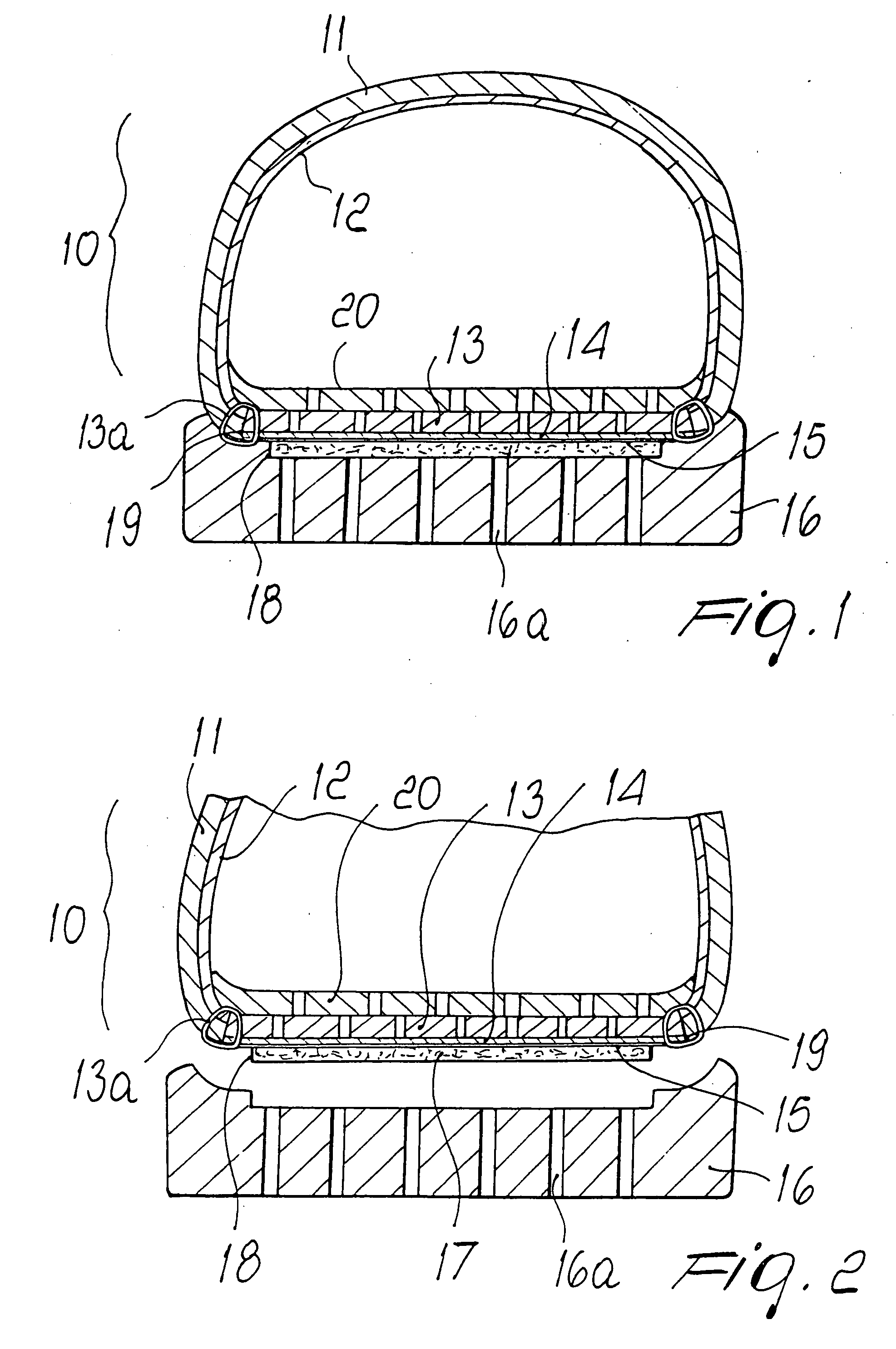

[0053] With particular reference to FIG. 3, in a second embodiment the shoe differs from the preceding case in that the protective element, now designated by the reference numeral 117, is sandwiched between two components 116a and 116b (which are mutually joined hermetically) into which the sole 116 is divided, each component having through holes 116c and 116d.

[0054] This is done if the thickness of the sole 116 is so great that it is difficult to clean it of any mud or dirt which might penetrate.

[0055] Being blocked by the protective element 117, in this case, the dirt can be released purely by virtue of the flexing of the sole, designated by the reference numeral 116.

[0056] The part above the protective element 117 of the sole 116 can act as an air chamber which increases comfort by absorbing any unevenness of the ground and increasing the ventilation of the membrane so as to rapidly dry its lower surface, when it is wet, in order to increase its breathability.

third embodiment

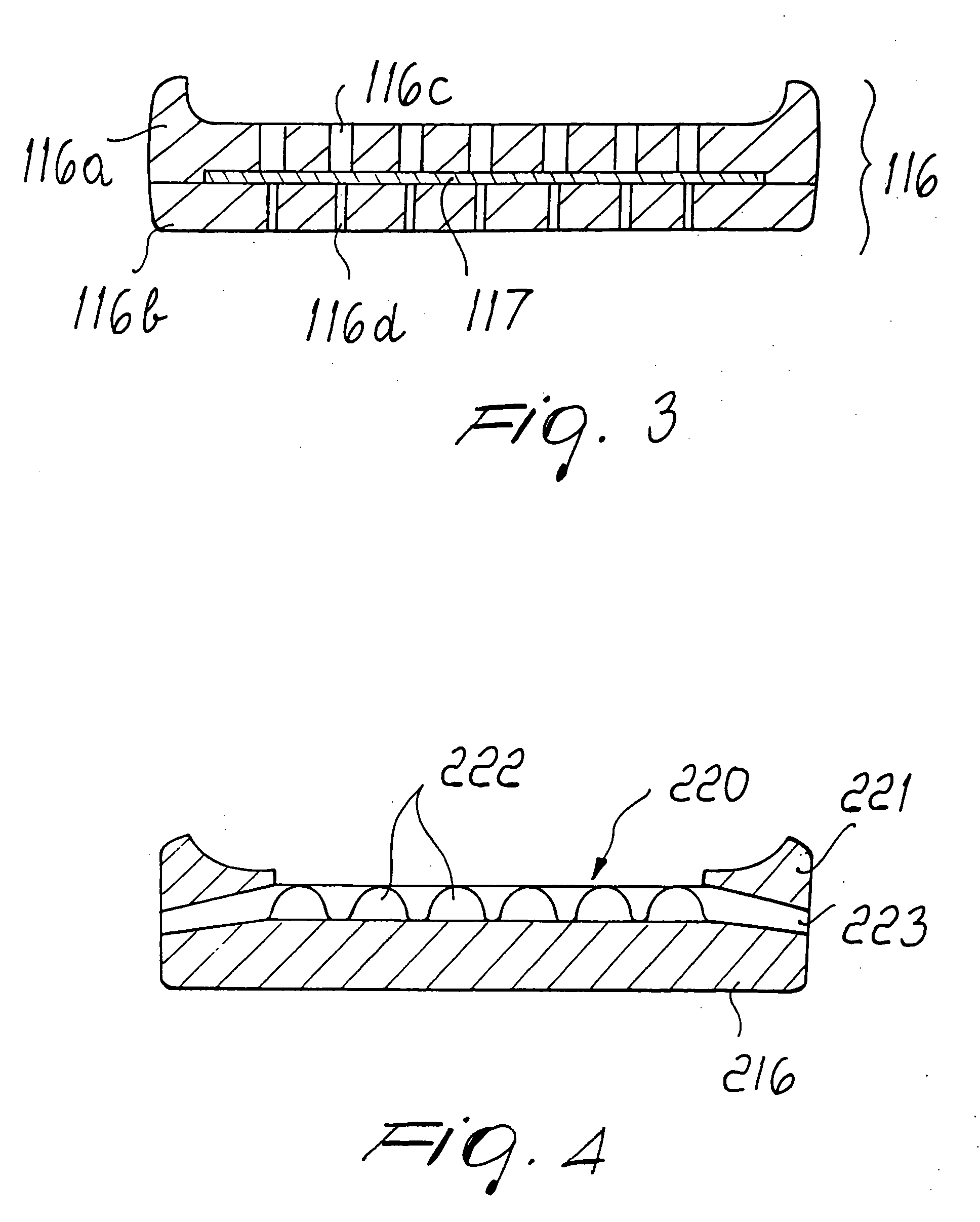

[0057] With particular reference to FIG. 4, a shoe according to the invention, in a third embodiment, differs from the preceding cases in that the sole, now designated by the reference numeral 216, has in its upper part a hollow region 220 which is delimited perimetrically by a border 221.

[0058] Dome-shaped protrusions 222 protrude from said hollow region 220, are uniformly distributed and advantageously reach the same height as said border 221.

[0059] Holes 223 or channels are provided in said border and connect the region 220 to the outside.

[0060] Each one of said holes 223 is inclined with respect to the ground contact plane, so that the outward part is lower than the inward part (this is done to avoid stagnation).

[0061] The holes 223 can furthermore be provided with one-way valves, not shown in the figures (which allow only air to flow outward).

PUM

| Property | Measurement | Unit |

|---|---|---|

| waterproof | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com