Method for manufacturing footwear, footwear produced using said method, and machine for manufacturing footwear

a manufacturing method and technology for footwear, applied in domestic footwear, applications, domestic applications, etc., can solve the problems of increasing the number of manufacturing operations and the time required to carry out such operations, assembling and turning parts, and flattening into a three-dimensional, so as to improve the manufacture of an article and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

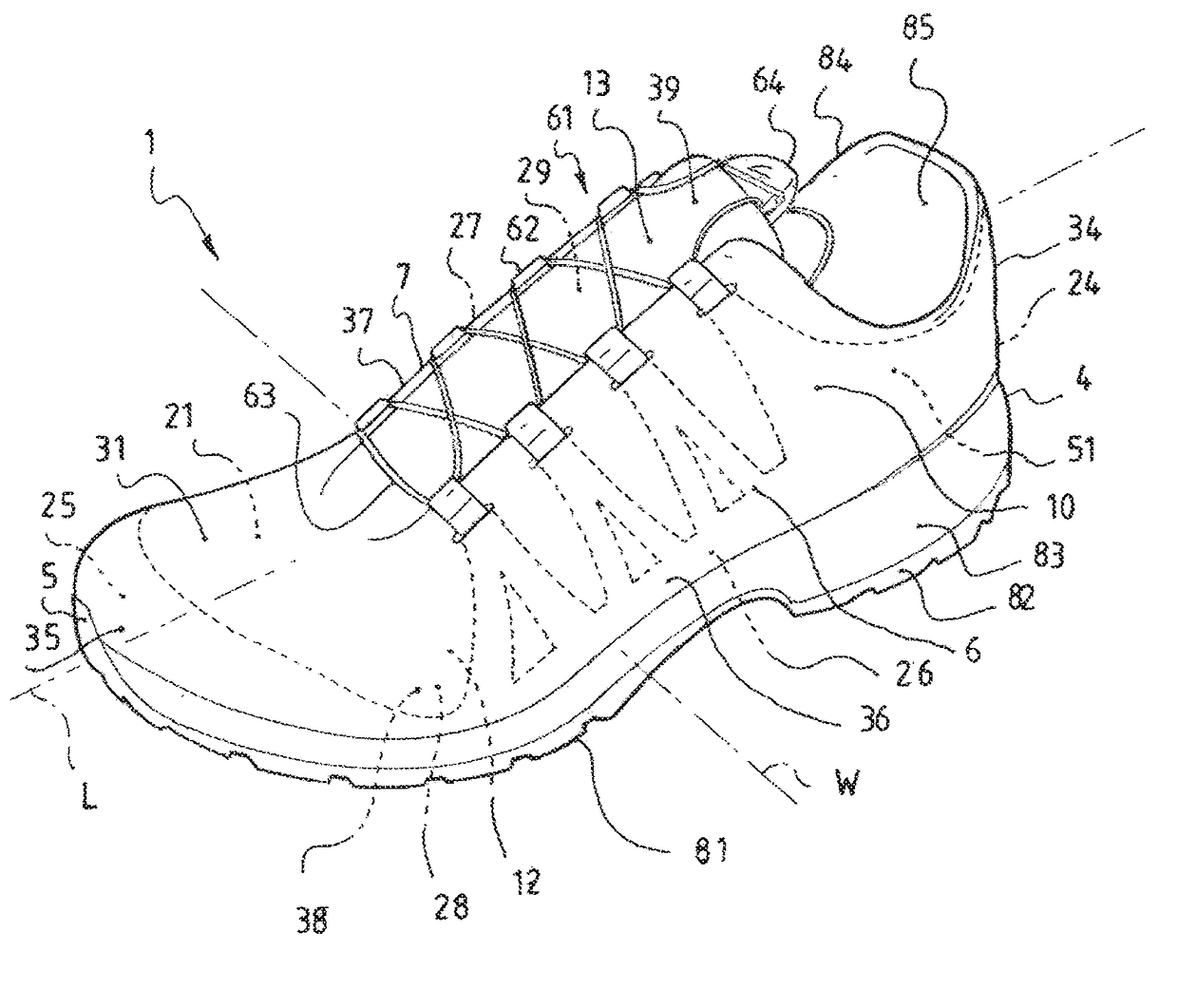

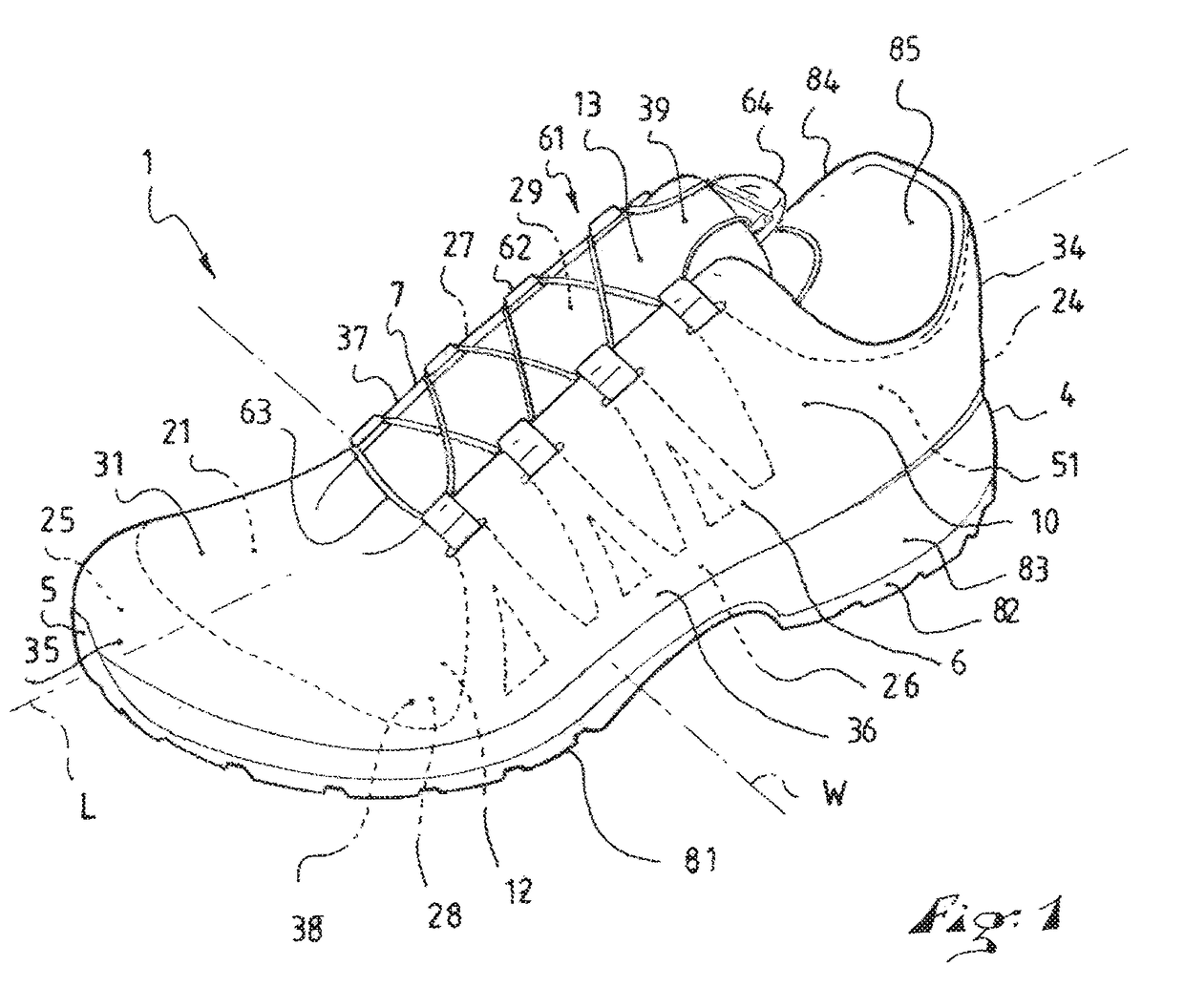

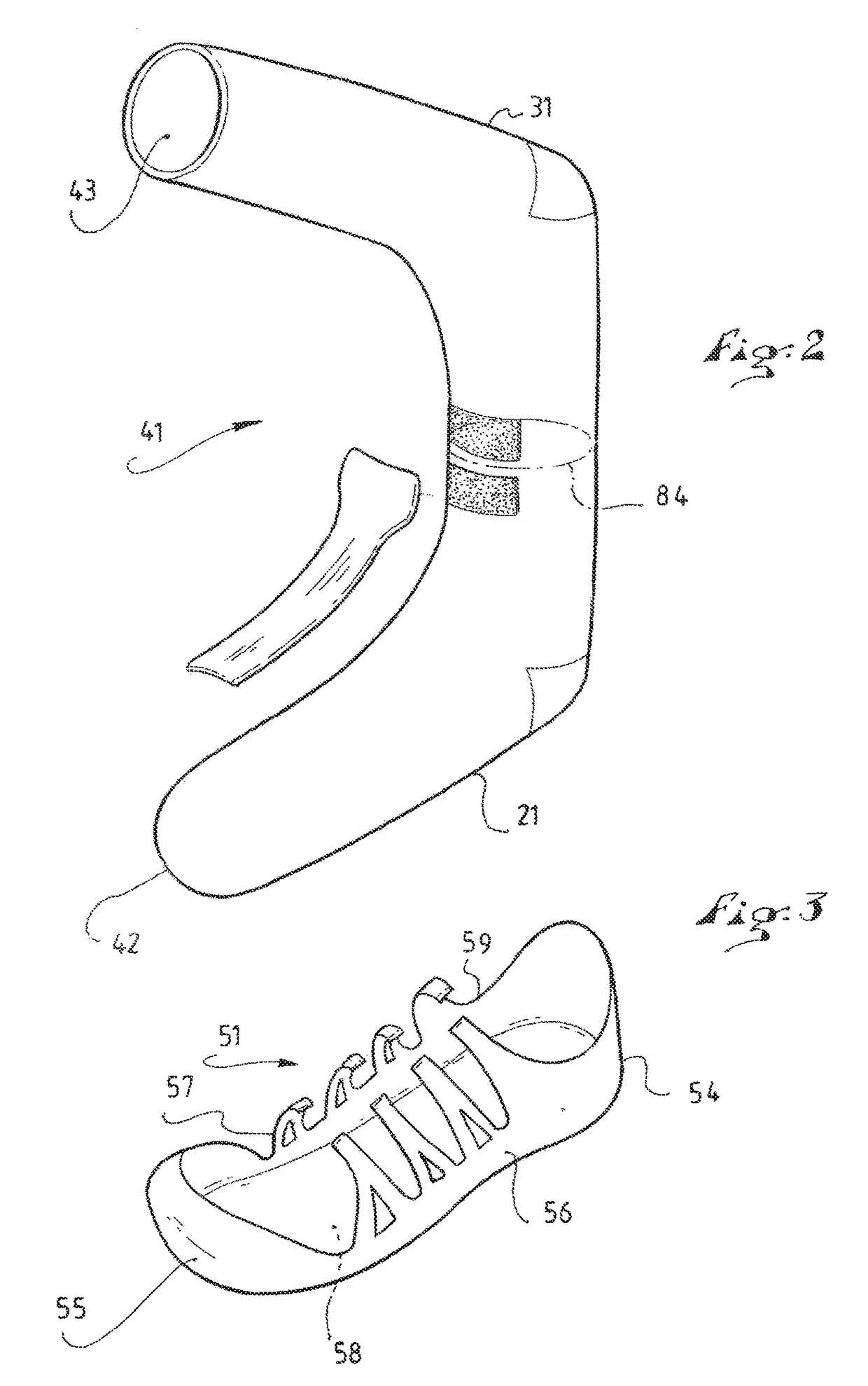

[0056]First, an article of footwear, and then a manufacturing method and machines for implementing the method, are described below with reference to all of the drawing figures.

[0057]As described below, the article of footwear is non-limitingly adapted for walking or running on flat or mountainous terrain. However, other fields of application are possible, such as ball-playing sports, racquet sports, or the like.

[0058]As shown in FIG. 1, an article of footwear 1 is provided to receive the foot of a user. For convenience, the article of footwear 1 will be considered as a shoe in the following description although, as will be shown in detail, its structure is completely unusual. Thus, the shoe 1 extends lengthwise along a longitudinal direction L, between a rear end, or heel 4, and a front end, or tip 5, and widthwise along a transverse direction W, between a lateral side 6 and a medial side 7.

[0059]As shown, the shoe 1 comprises a lower portion 10, provided to surround the foot, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion strength | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com