High-voltage charged overhead bare wire intelligent rubber-coated spraying robot

A spraying robot, high-voltage charging technology, applied in the field of electric power system, can solve the problems of poor coating effect of bare wires, prone to leakage, poor fixing effect of bare wires, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described in detail below.

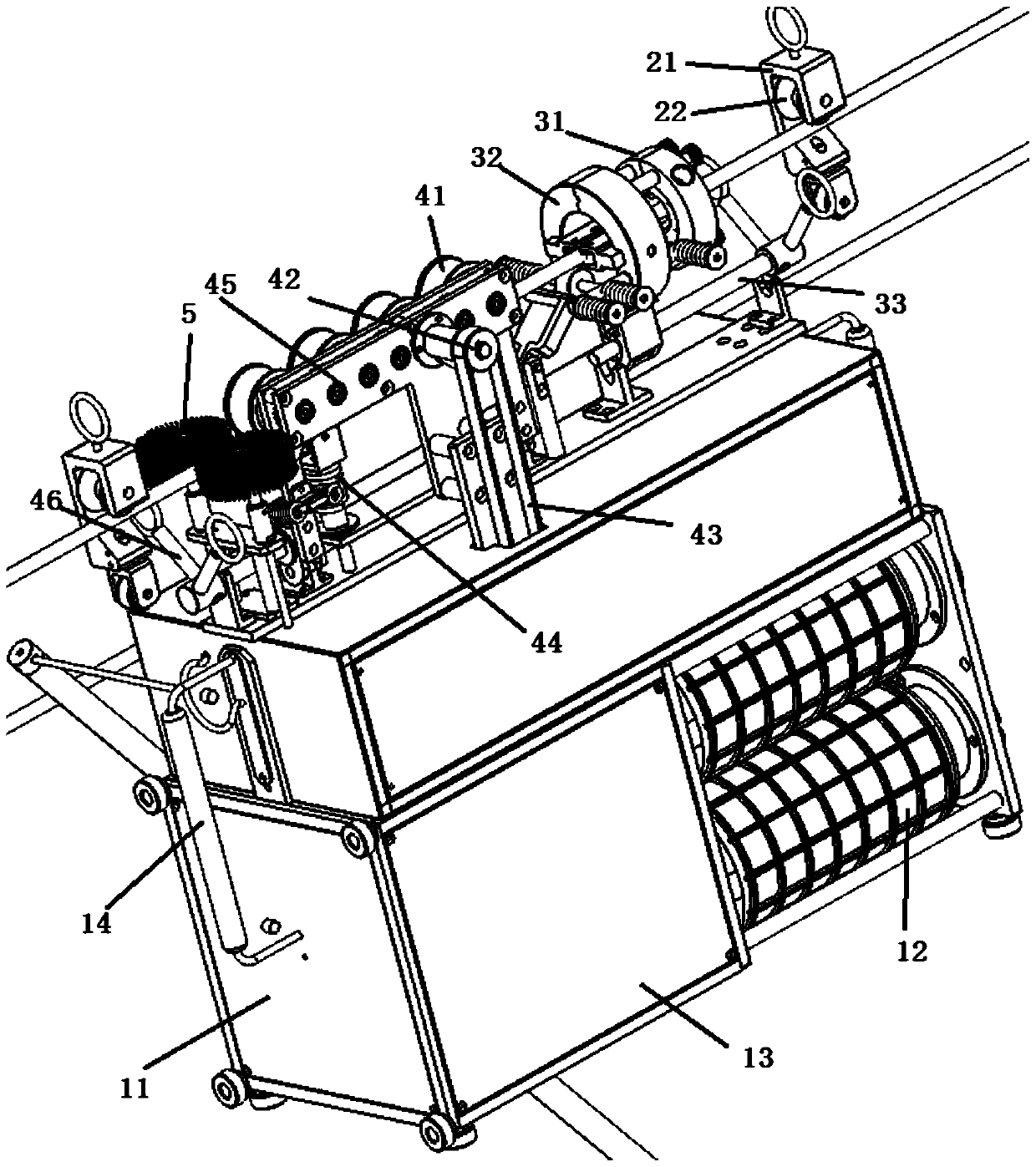

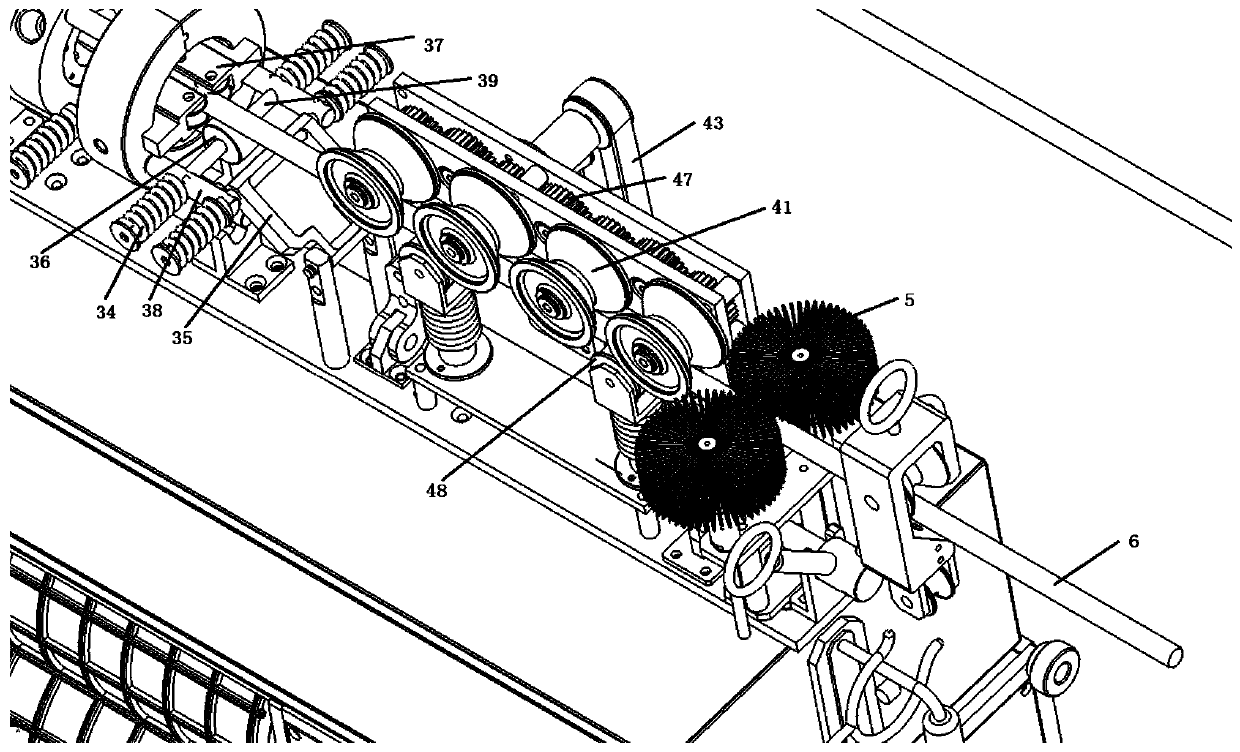

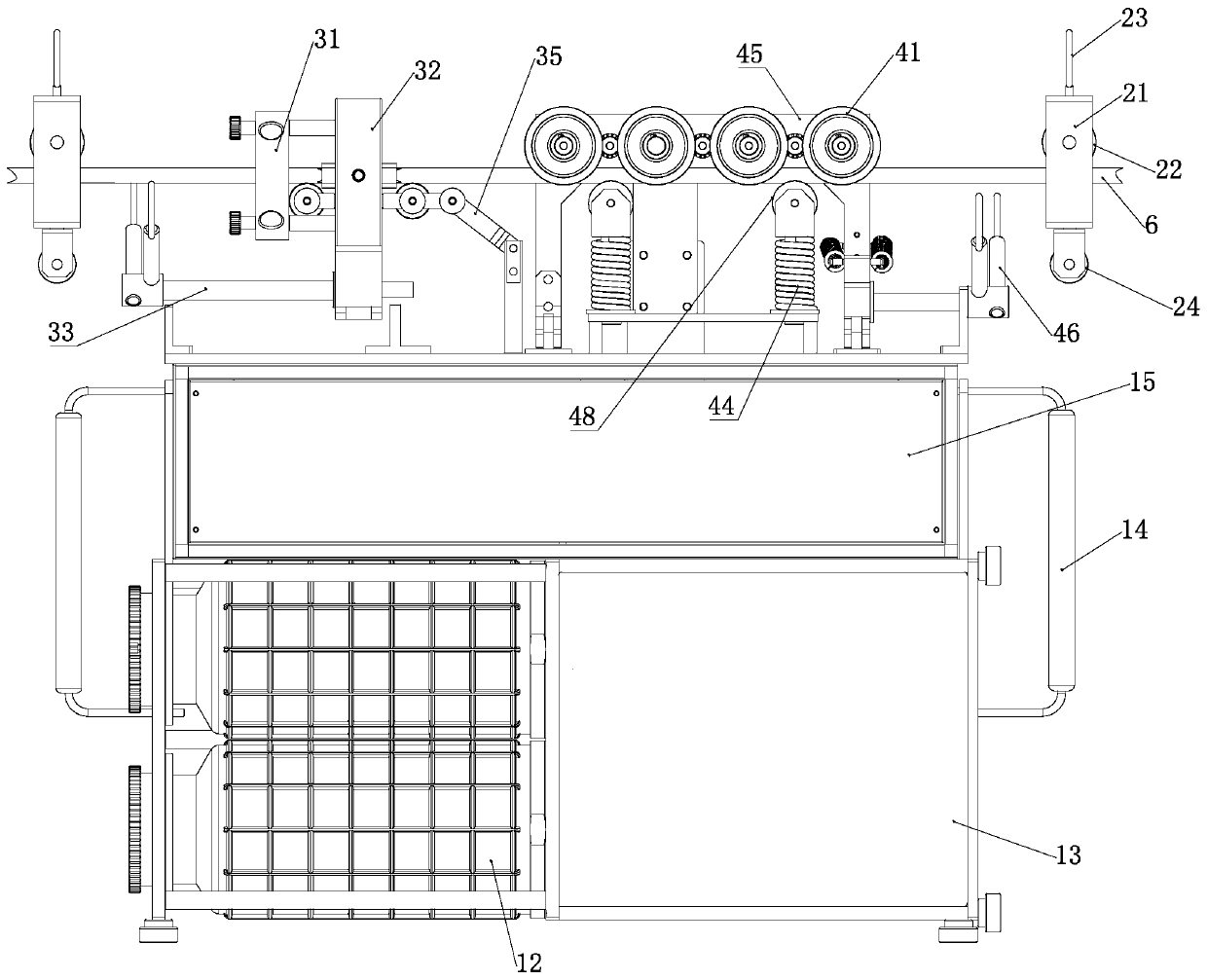

[0030] The reference signs in the accompanying drawings of the specification include:

[0031] Cabinet 11, insulating paint bucket 12, sliding door 13, handle 14, motor box 15, locking block 21, third locking wheel 22, suspension ring 23, pulley 24, injection molding pressure ring 31, clamping arm 32, connecting rod 33. The first compression spring 34, the rotating arm 35, the first roller 36, the clamping block 37, the fixed rod 38, the pressure rod 39, the second locking wheel 41, the driven wheel 42, the conveyor belt 43, the second compression spring 44, Position plate 45, second rocking handle 46, gear 47, second roller 48, cleaning brush 5, bare wire 6.

[0032] Such as Figure 1~3 The shown high-voltage live overhead bare wire intelligent coating spraying robot includes a cabinet 11, a suspension device for hanging the bare wire 6, a glue injection device for coating the bare wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com