Polybutylene terephthalate composition for TPE encapsulation and preparation method thereof

A technology of polybutylene terephthalate and composition, applied in the field of polybutylene terephthalate composition and preparation thereof, can solve the problem of almost no reports on improving PBT materials, limiting the application of PBT materials, Problems such as poor coating adhesion, to achieve the effect of improving the coating effect, low warpage, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0046] The present invention will be described in detail below in conjunction with examples.

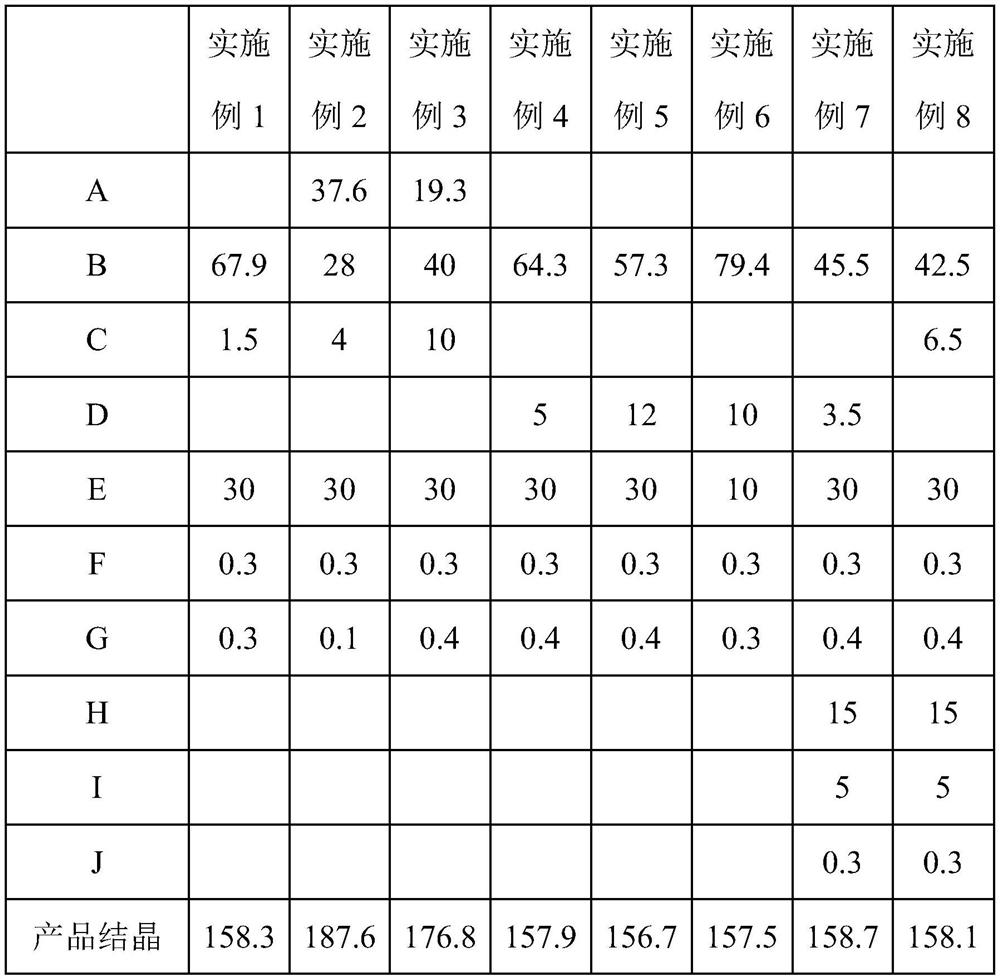

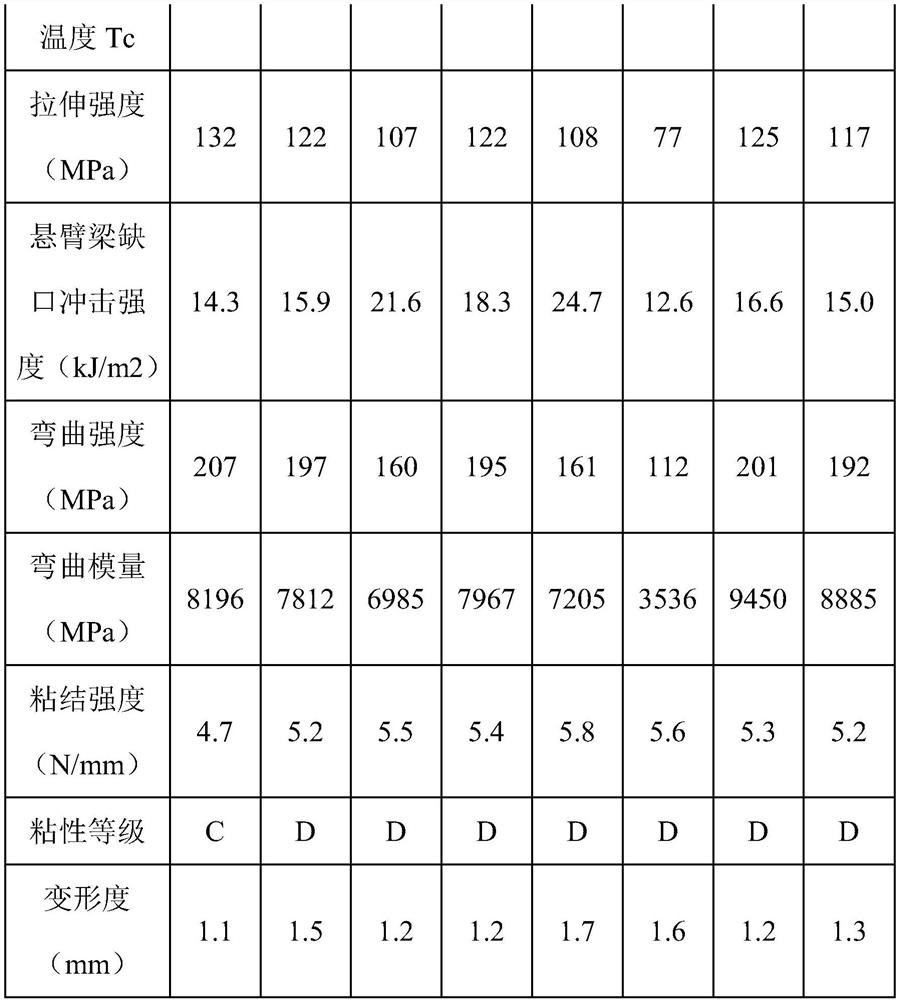

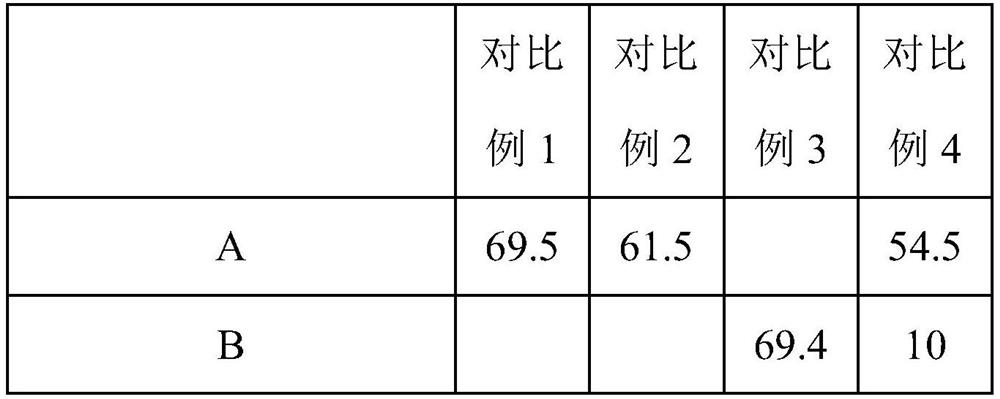

[0047] Raw material kind is selected as follows in embodiment and comparative example:

[0048] PBT resin A, the model is PBT GX121, conventional PBT resin, Tc is 180.4 ° C, relative density is 1.31, intrinsic viscosity is 1.00dl / g, purchased from Sinopec Asset Management Co., Ltd. Yizheng Branch;

[0049] PBT resin B, the model is PBT DR905, PBT copolyester, Tc is 127.5°C, relative density is 1.31, intrinsic viscosity is 0.95dl / g, purchased from Sinopec Asset Management Co., Ltd. Yizheng Branch;

[0050] Toughener C, POE-g-MAH, the model is FUSABONDN493, the grafting rate of MAH is about 0.6%, purchased from Shanghai Branch of DuPont China Group Co., Ltd.;

[0051] Toughener D, E-BA-GMA copolymer, model Elvaloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com