Patents

Literature

46results about How to "Improve lagging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

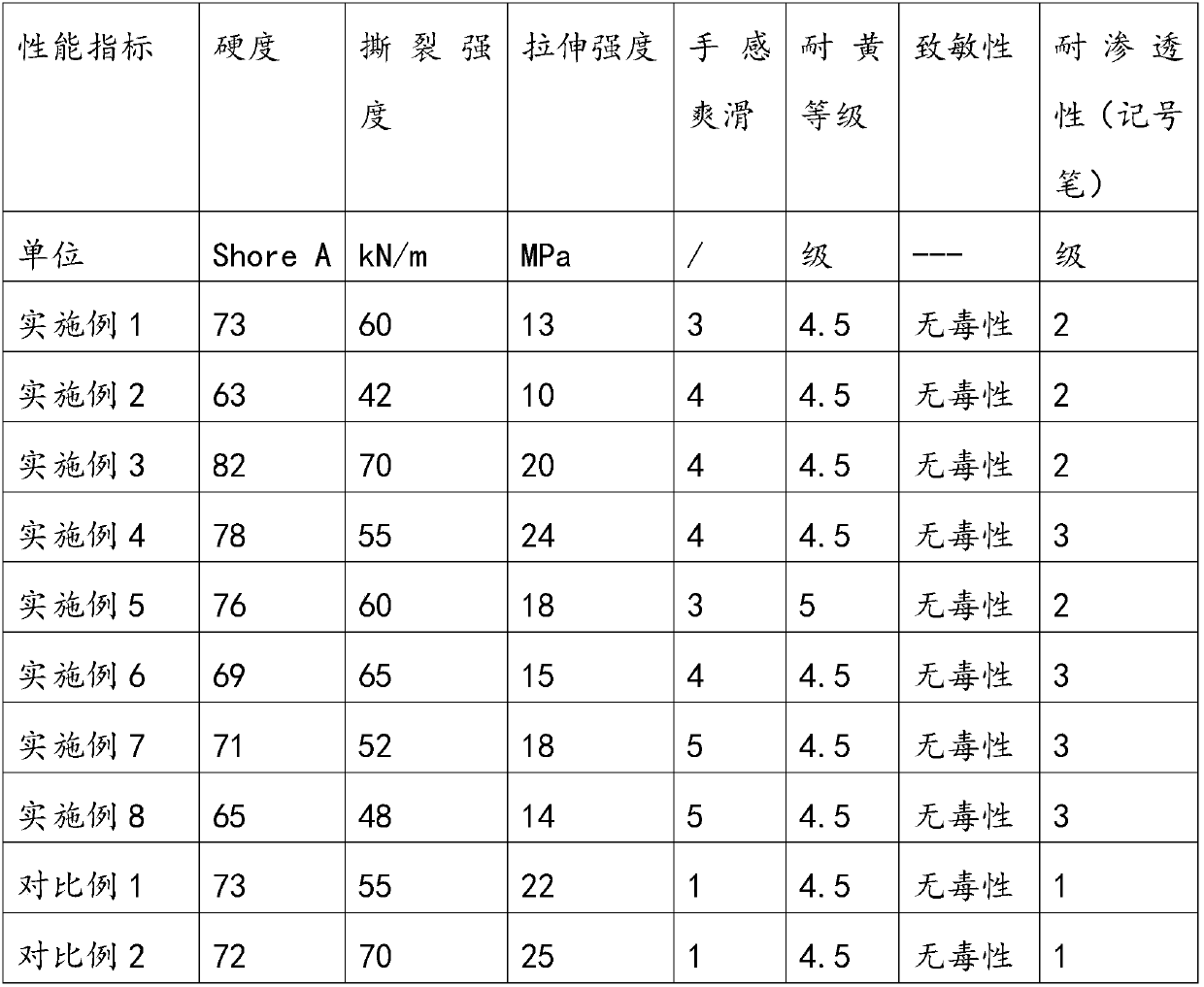

Thermoplastic organic silicon polyurethane elastomer and preparation method thereof

Owner:MIRACLL CHEM

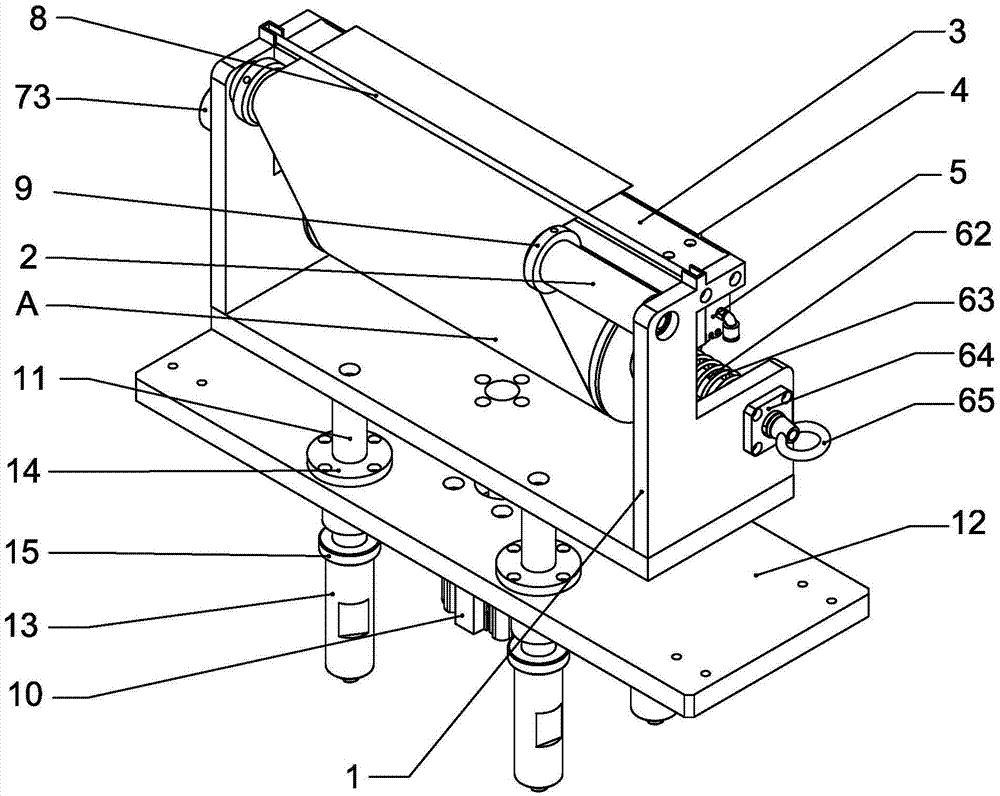

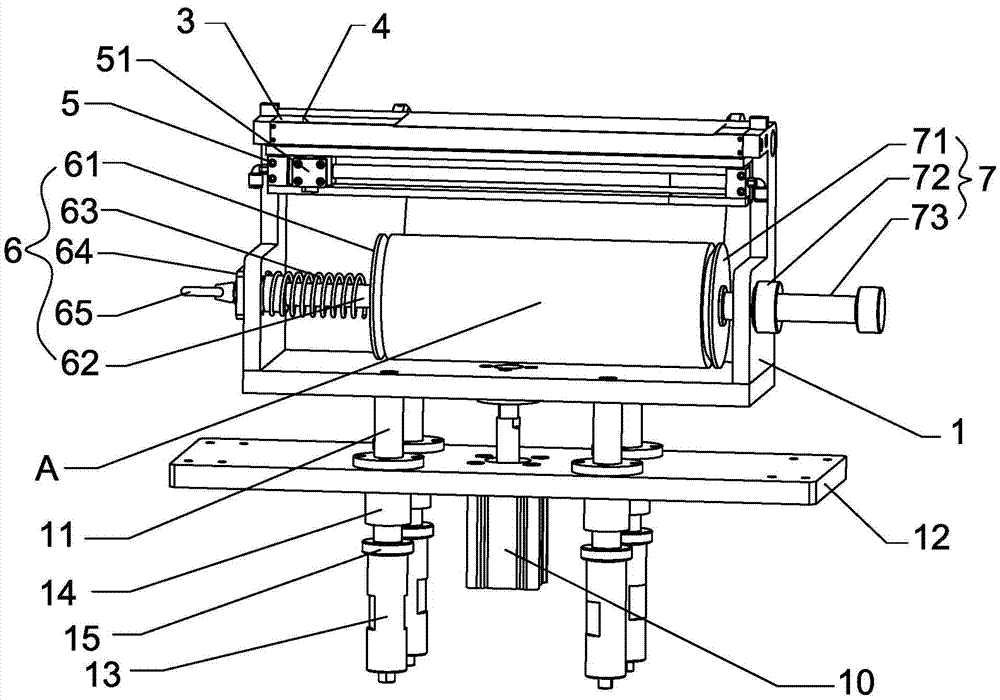

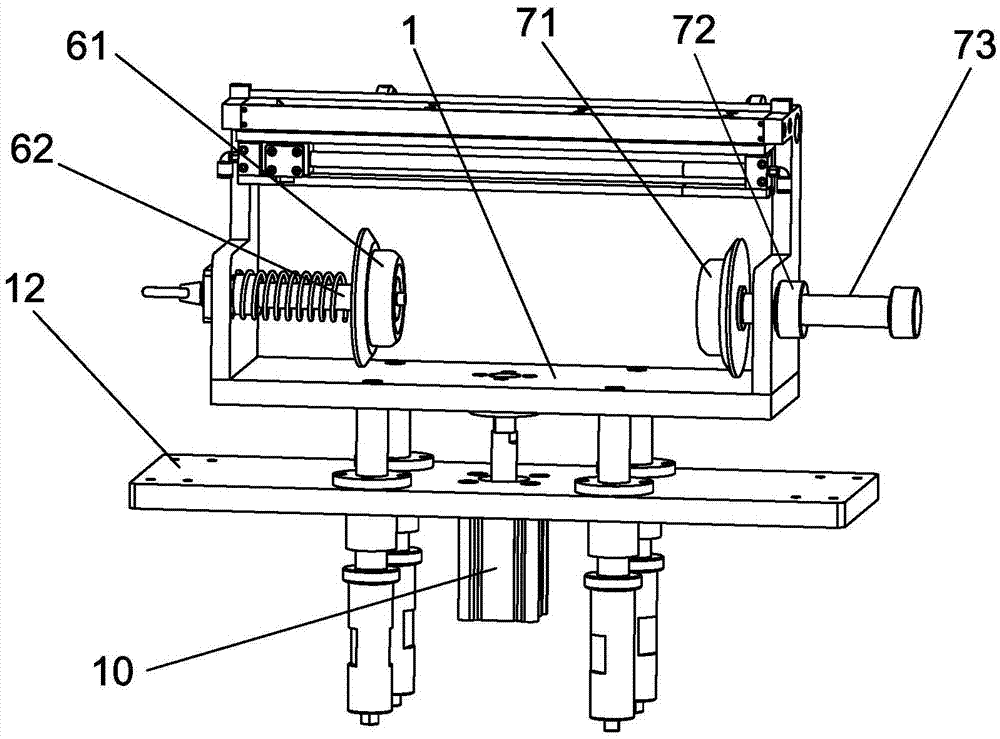

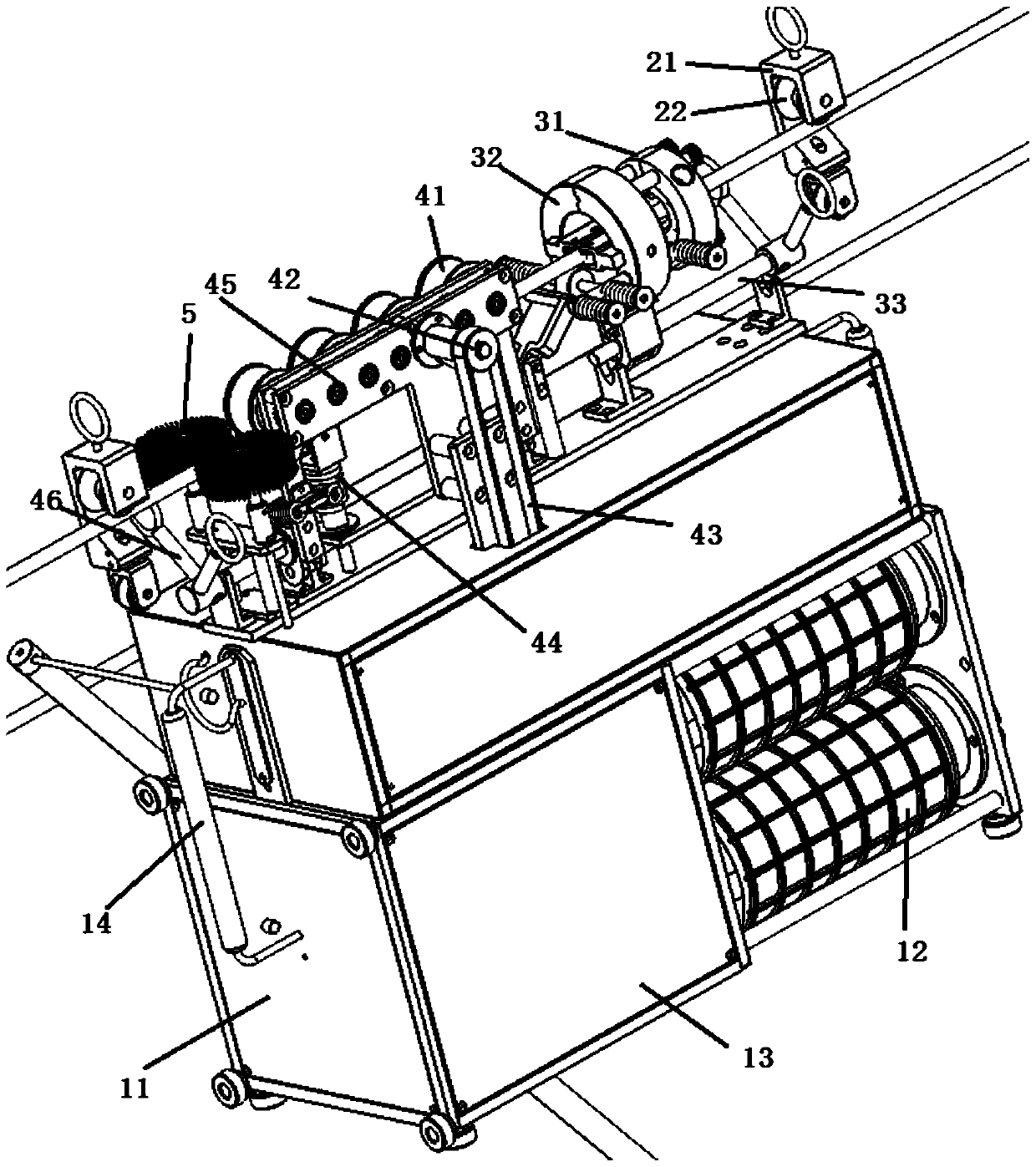

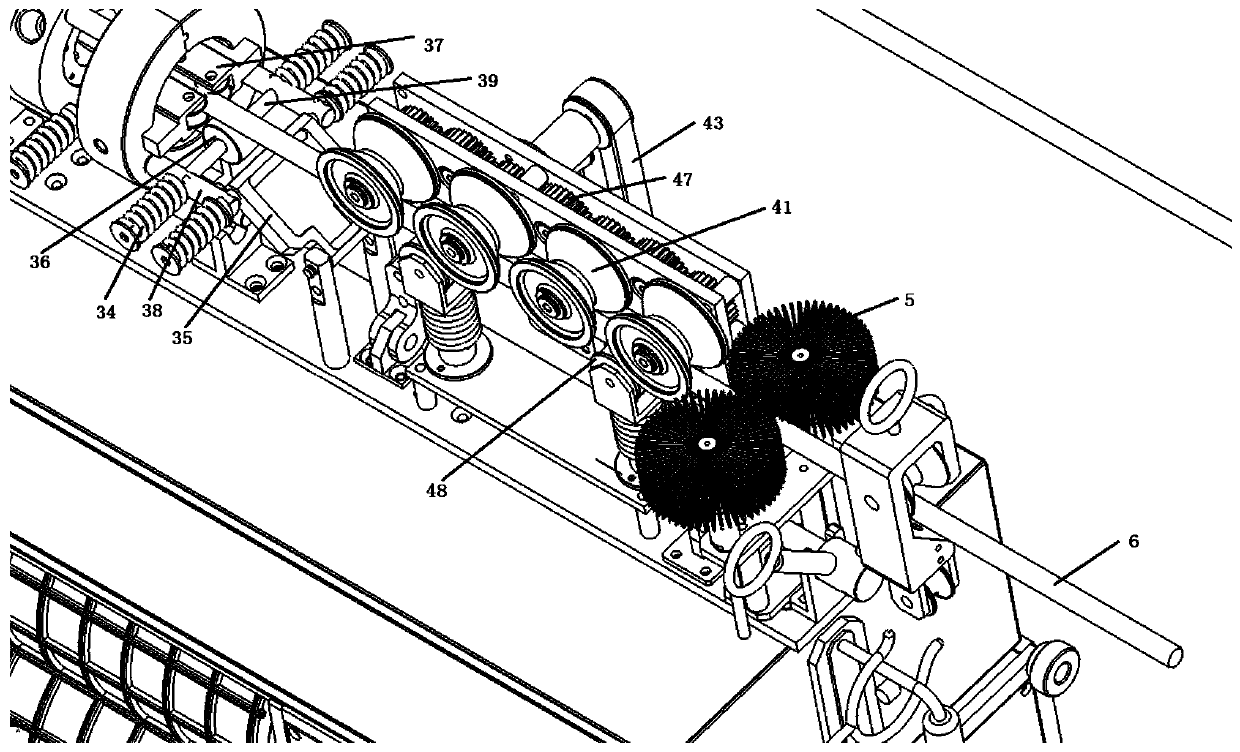

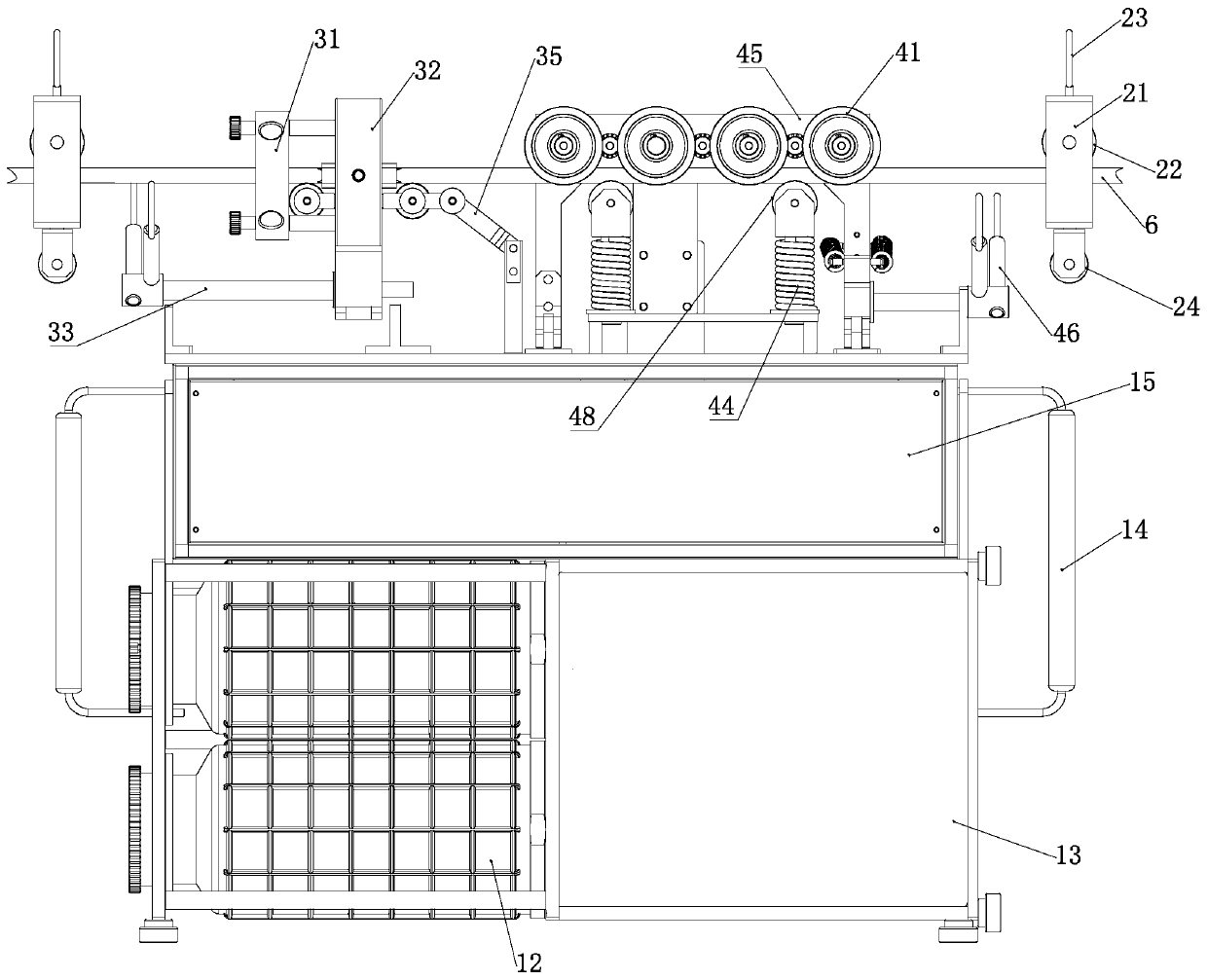

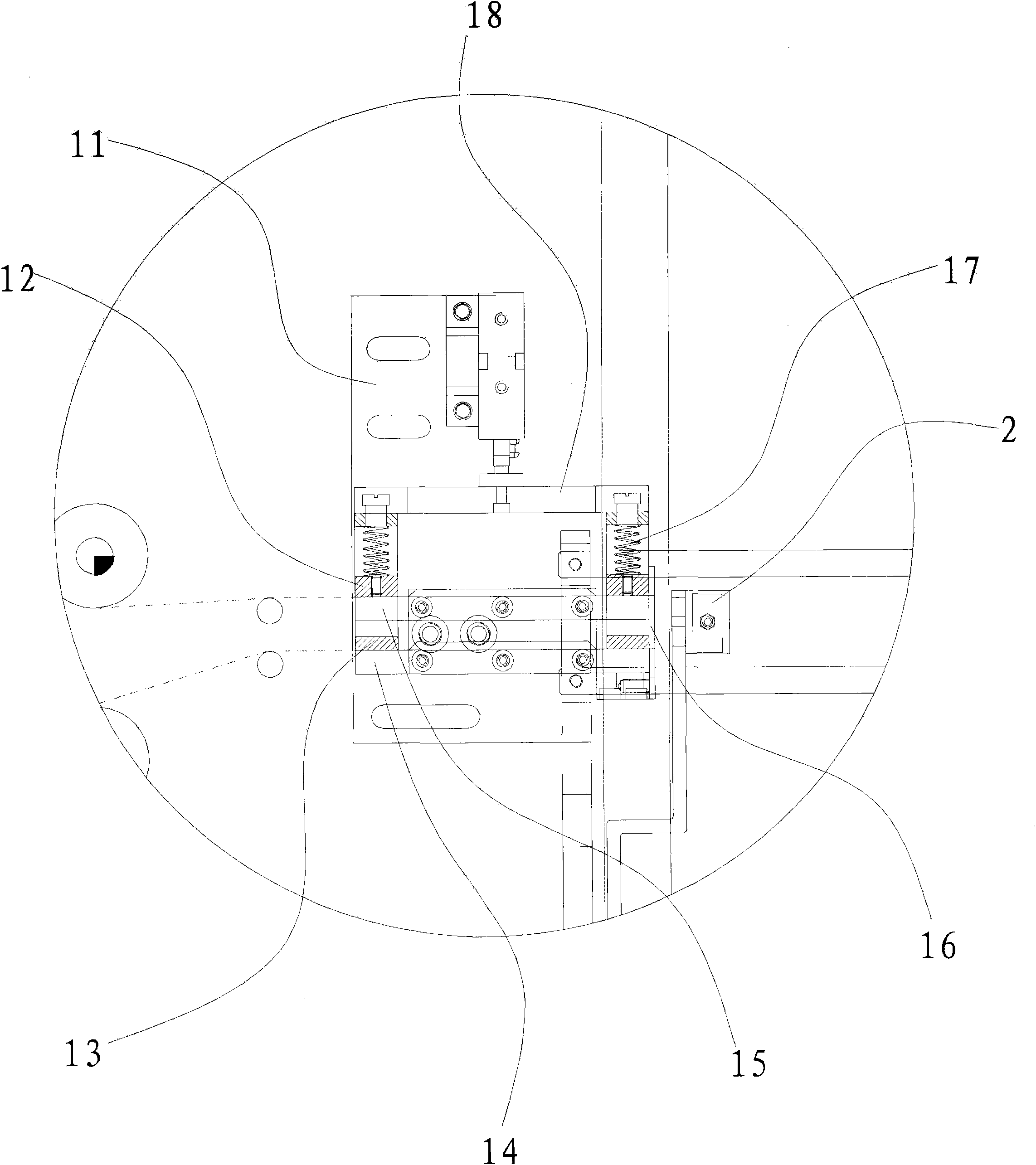

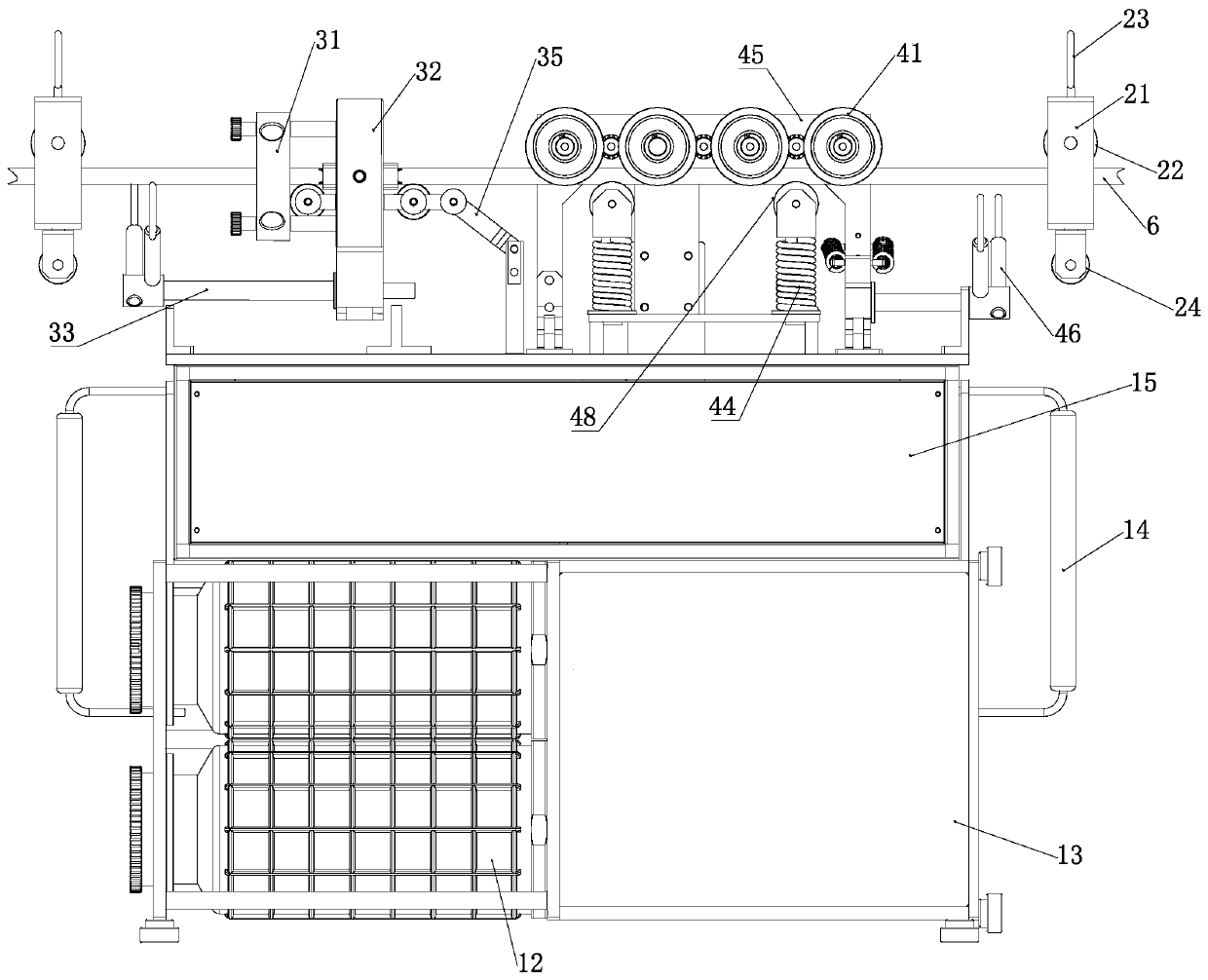

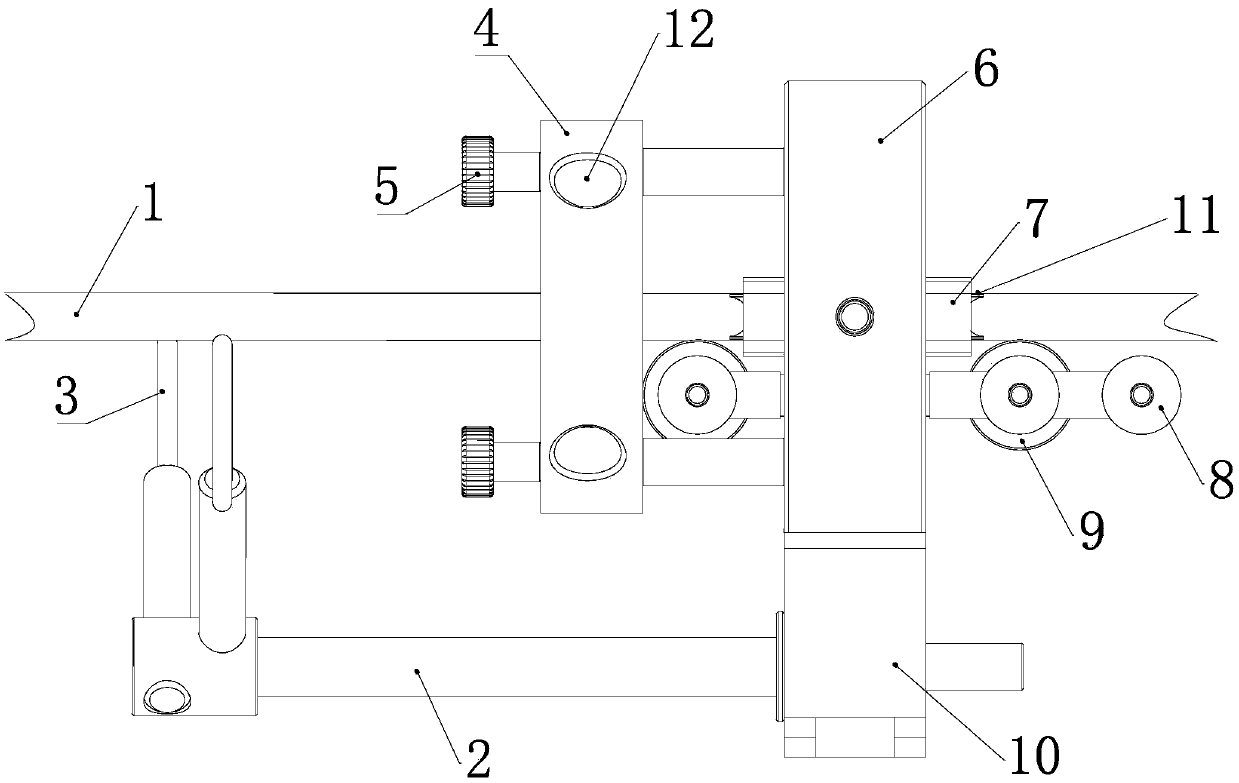

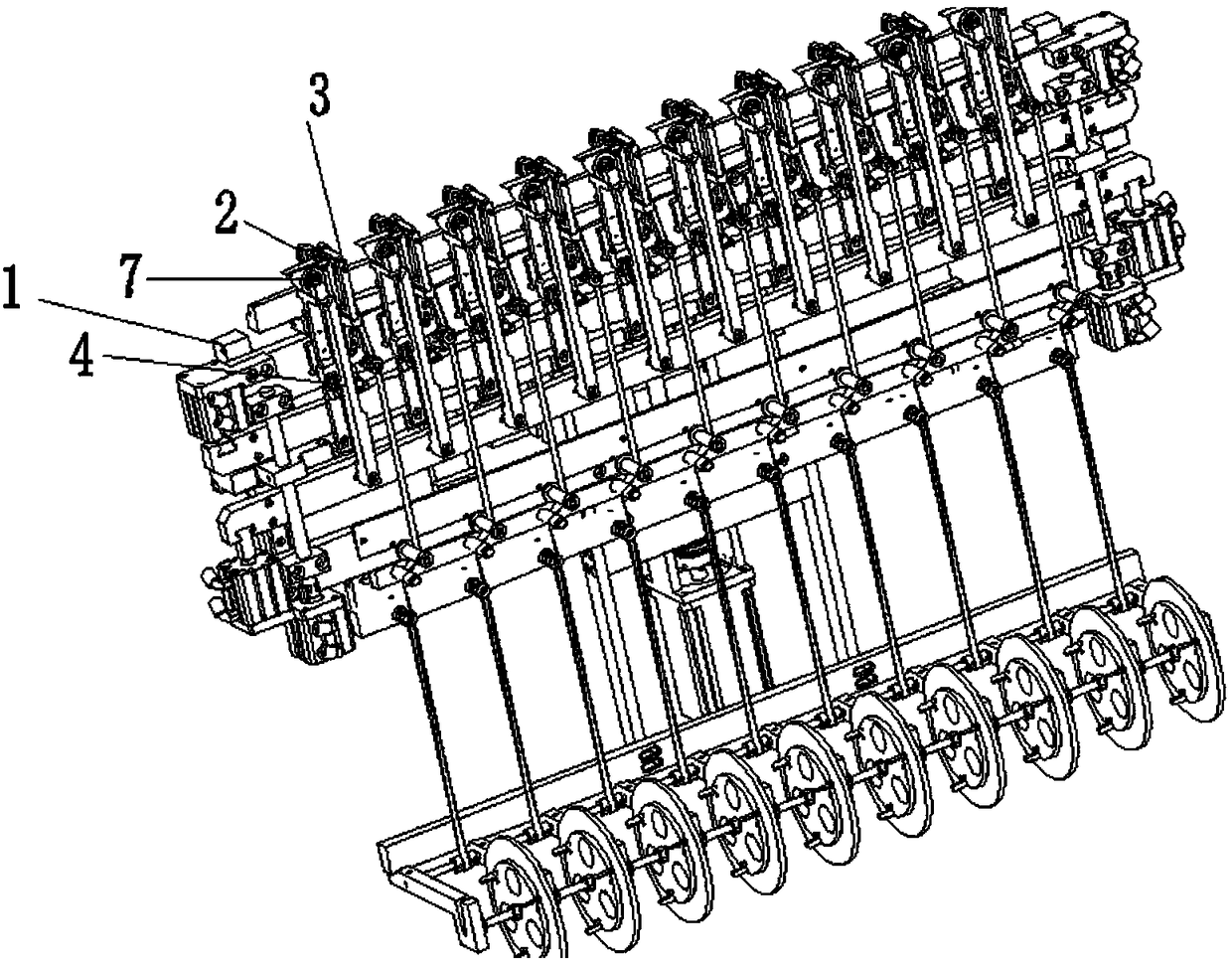

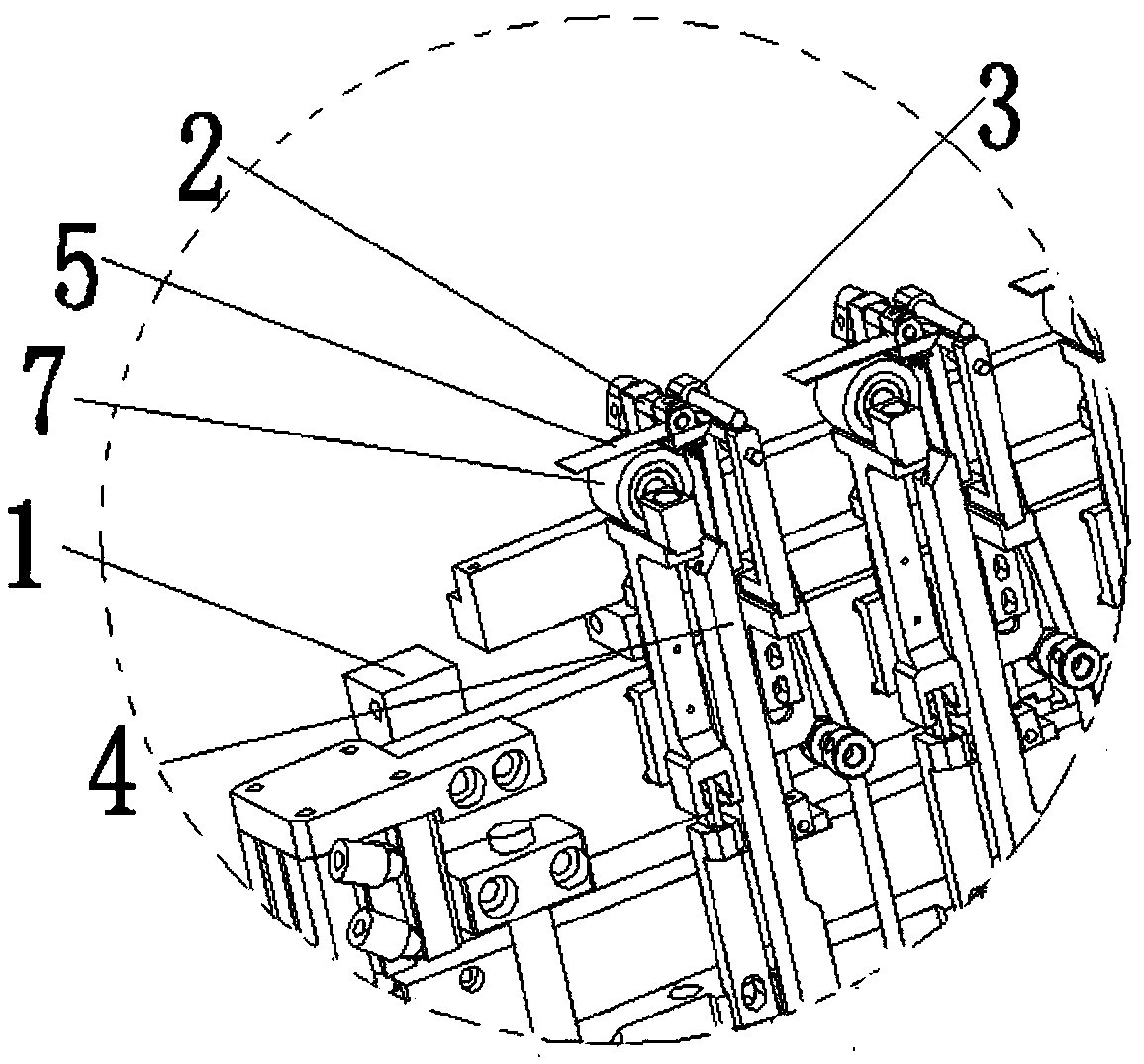

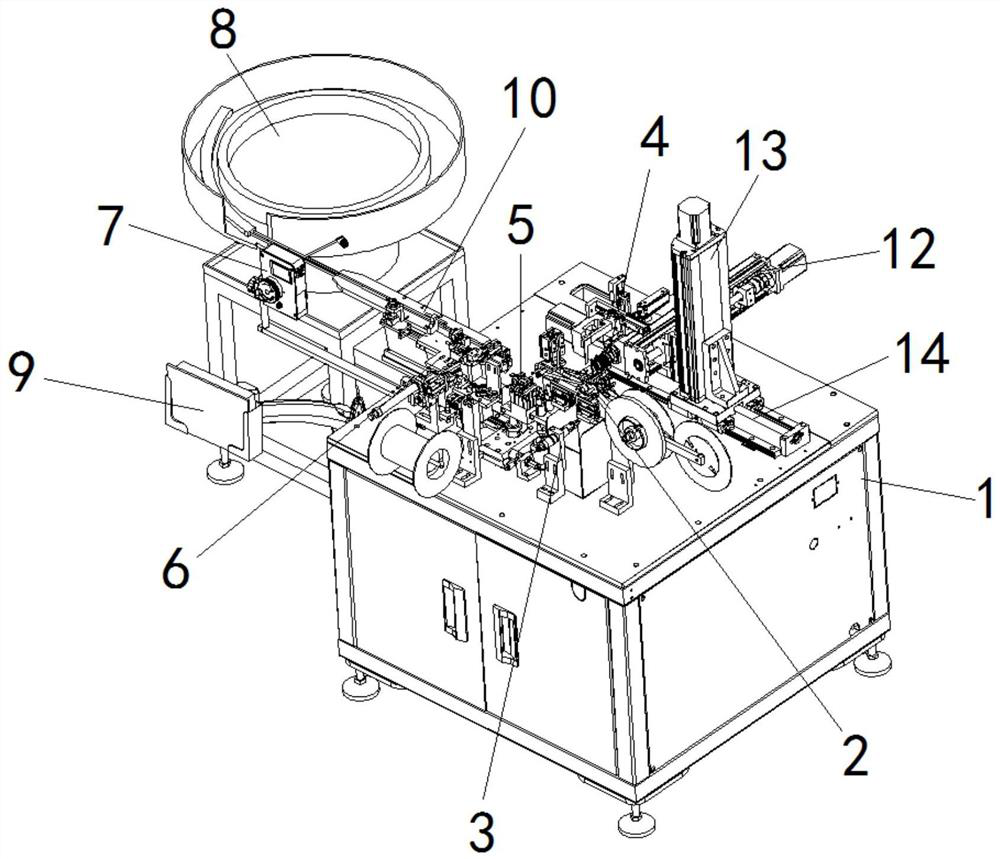

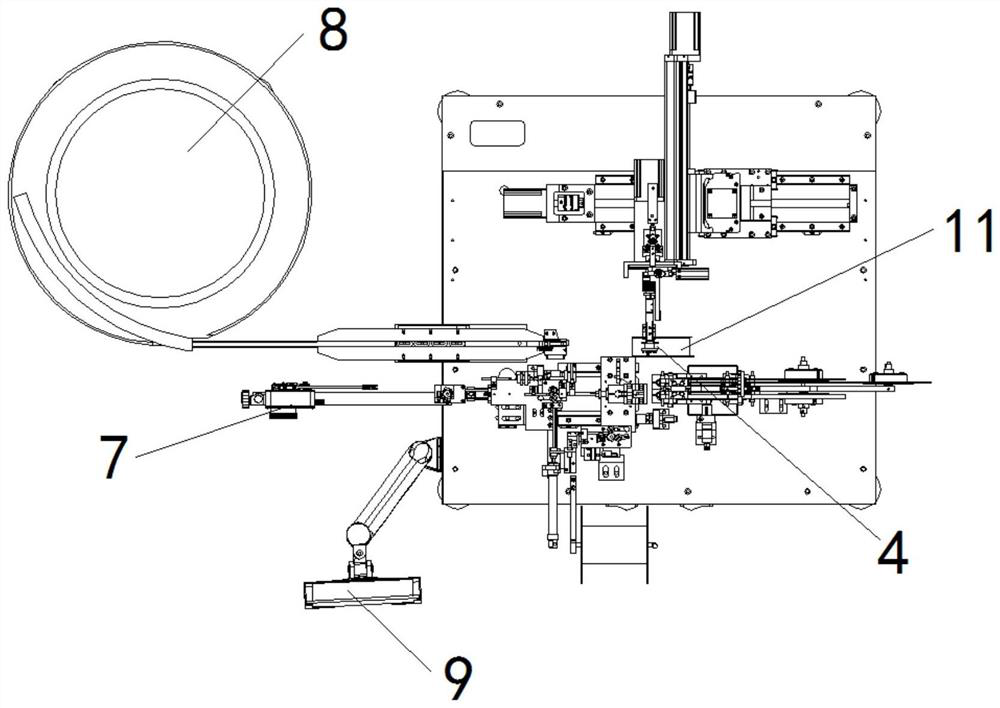

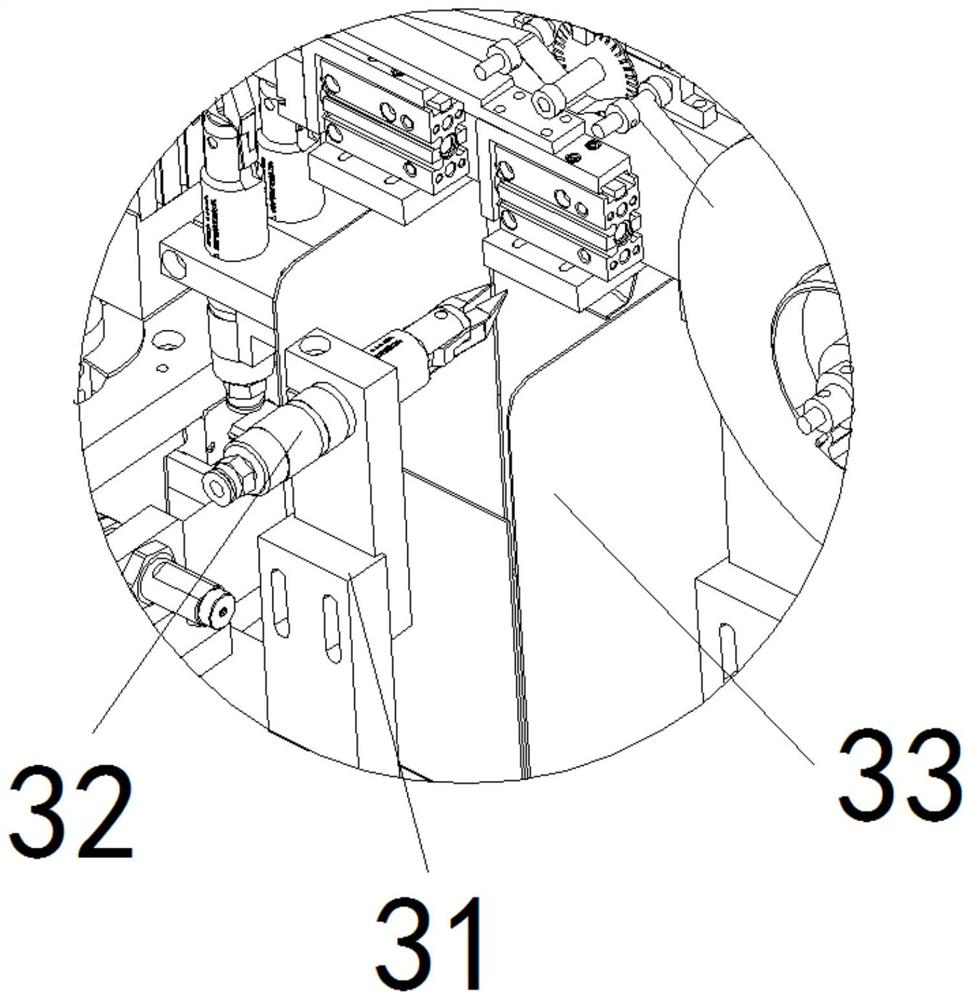

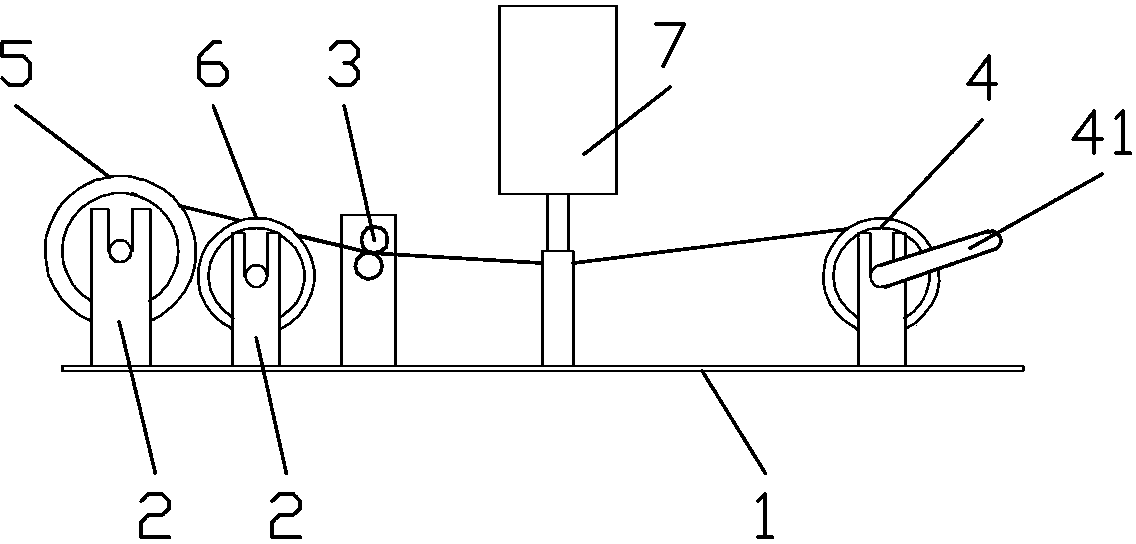

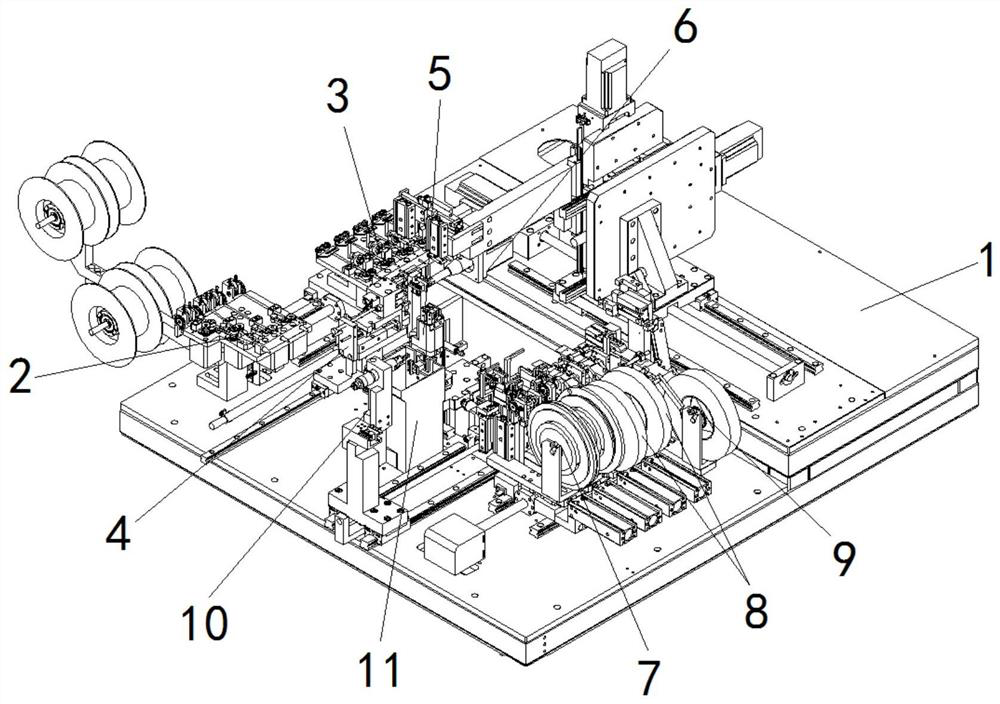

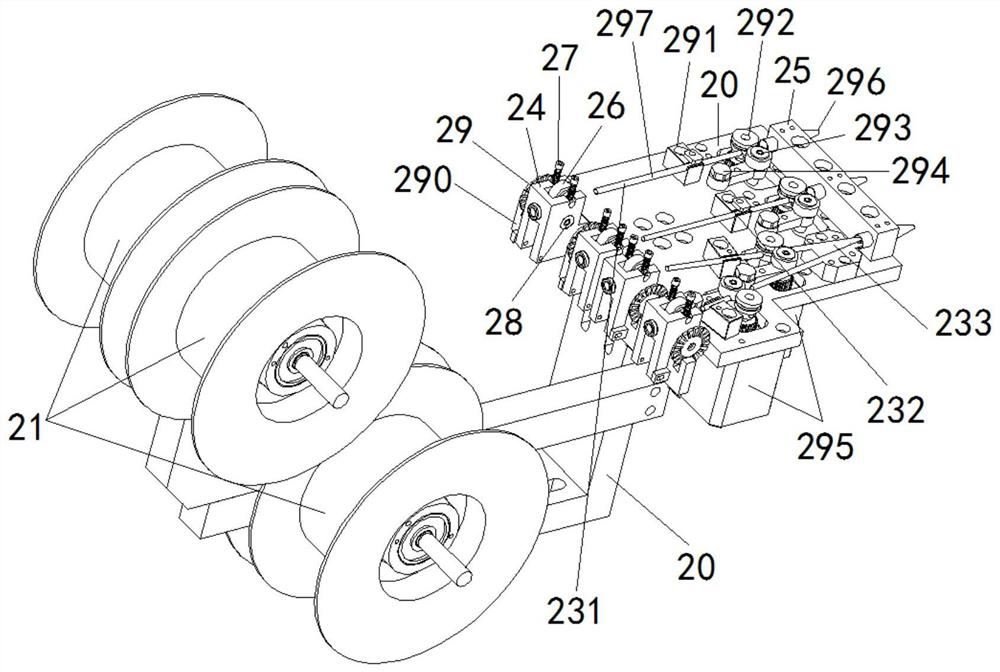

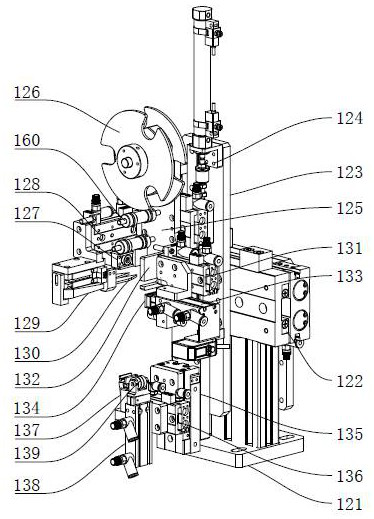

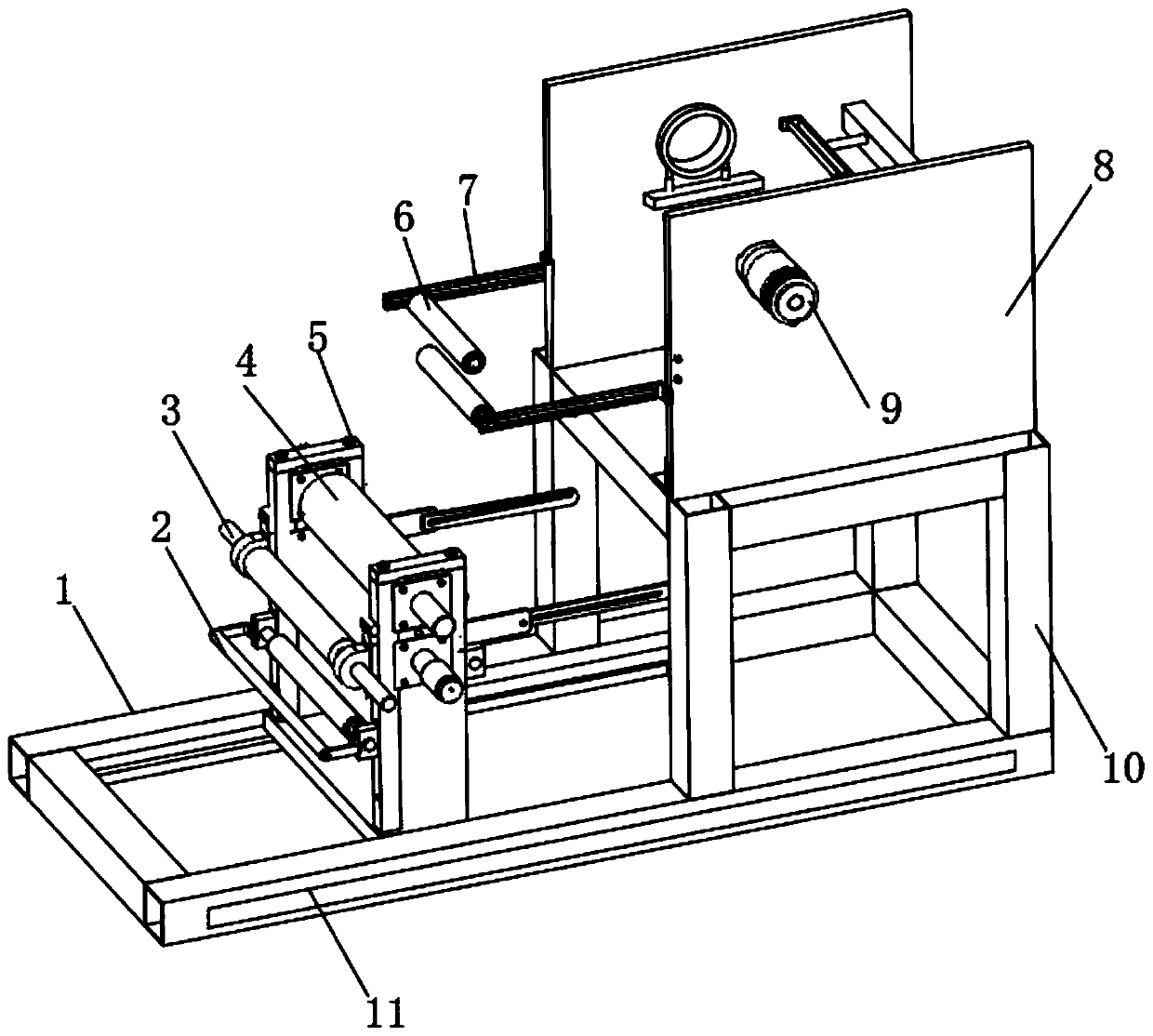

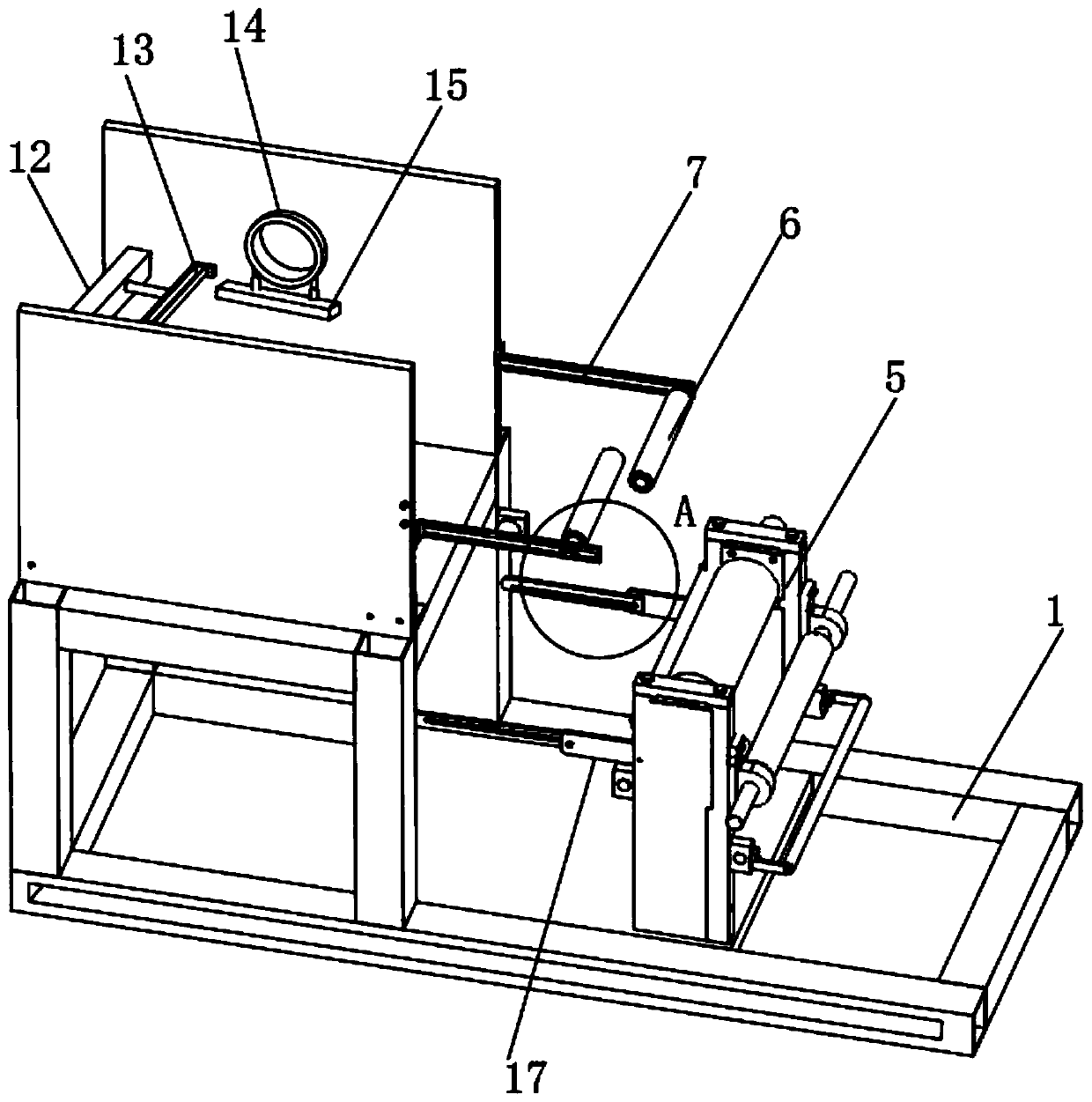

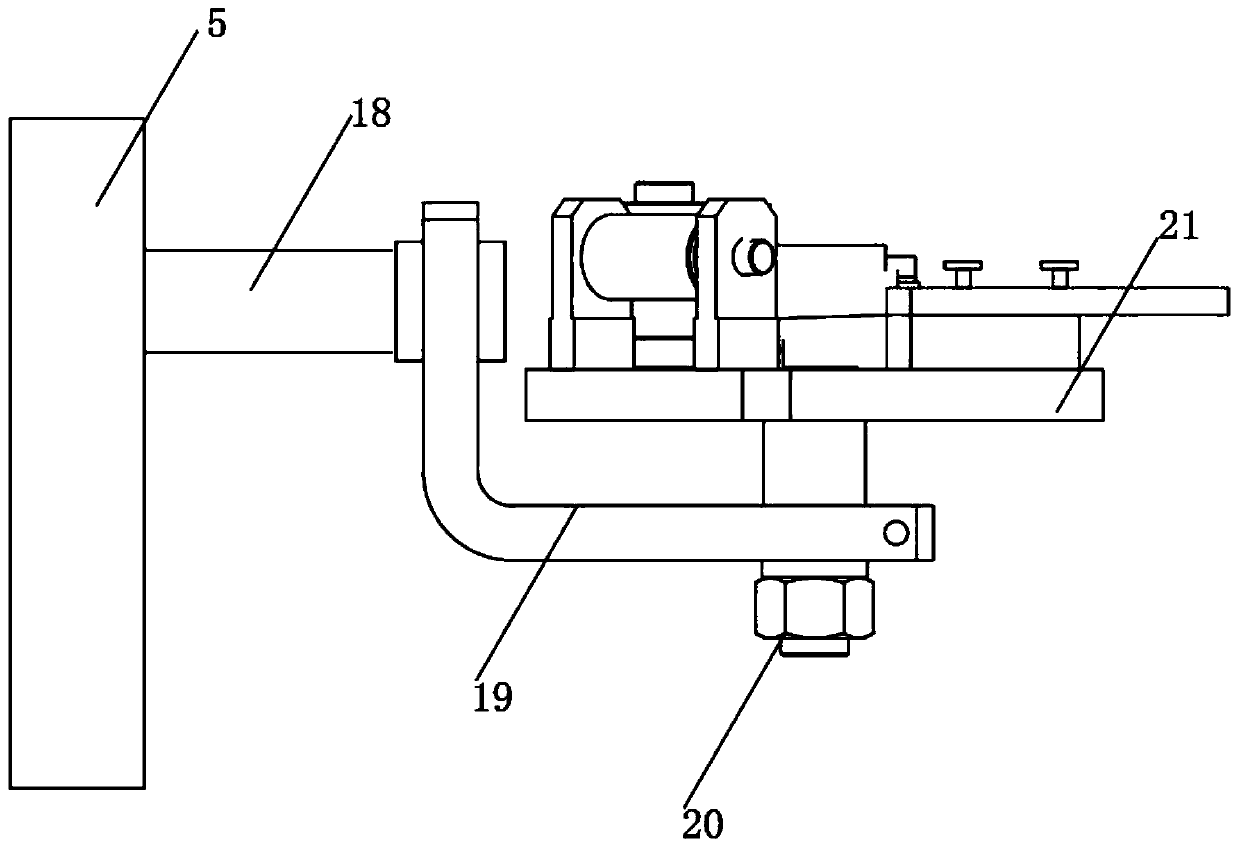

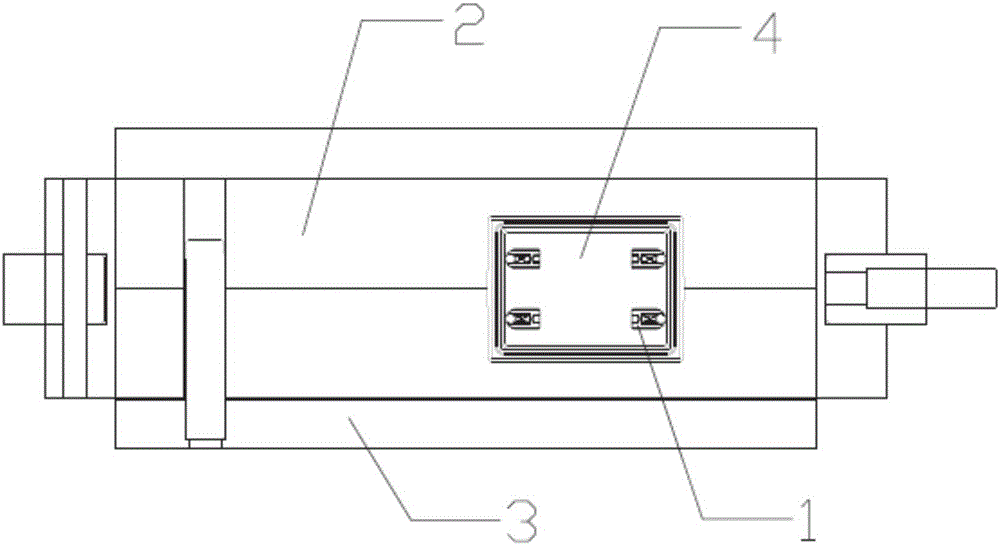

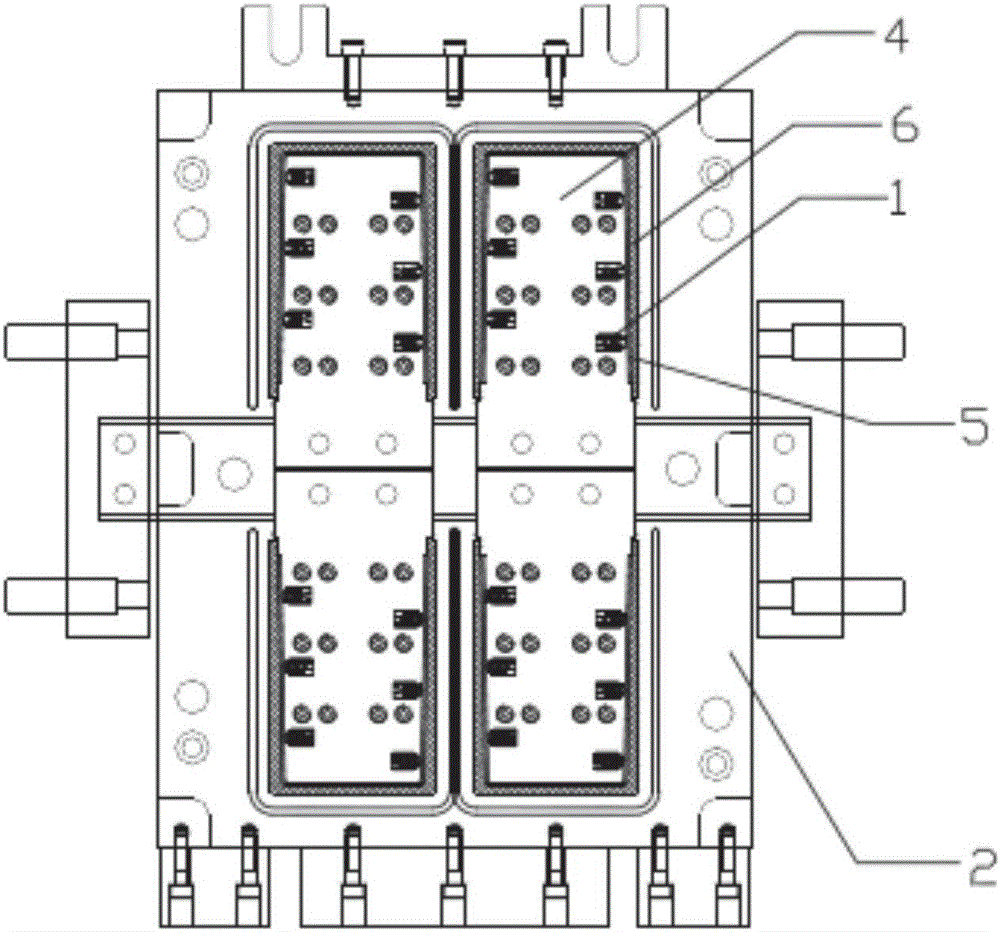

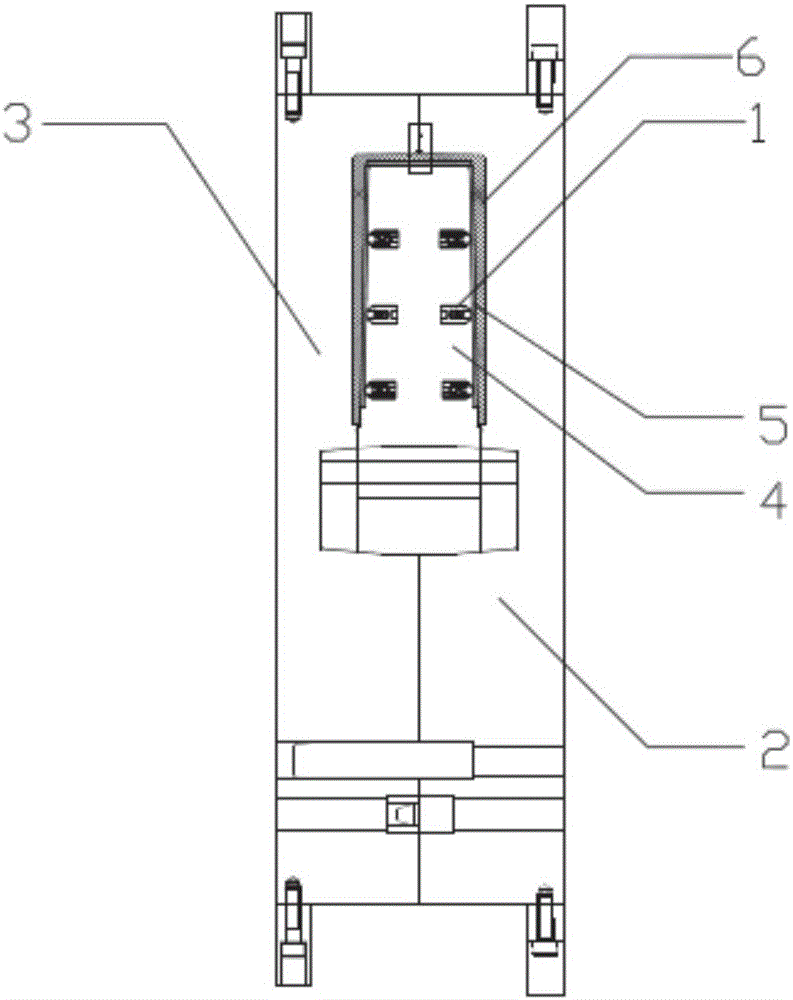

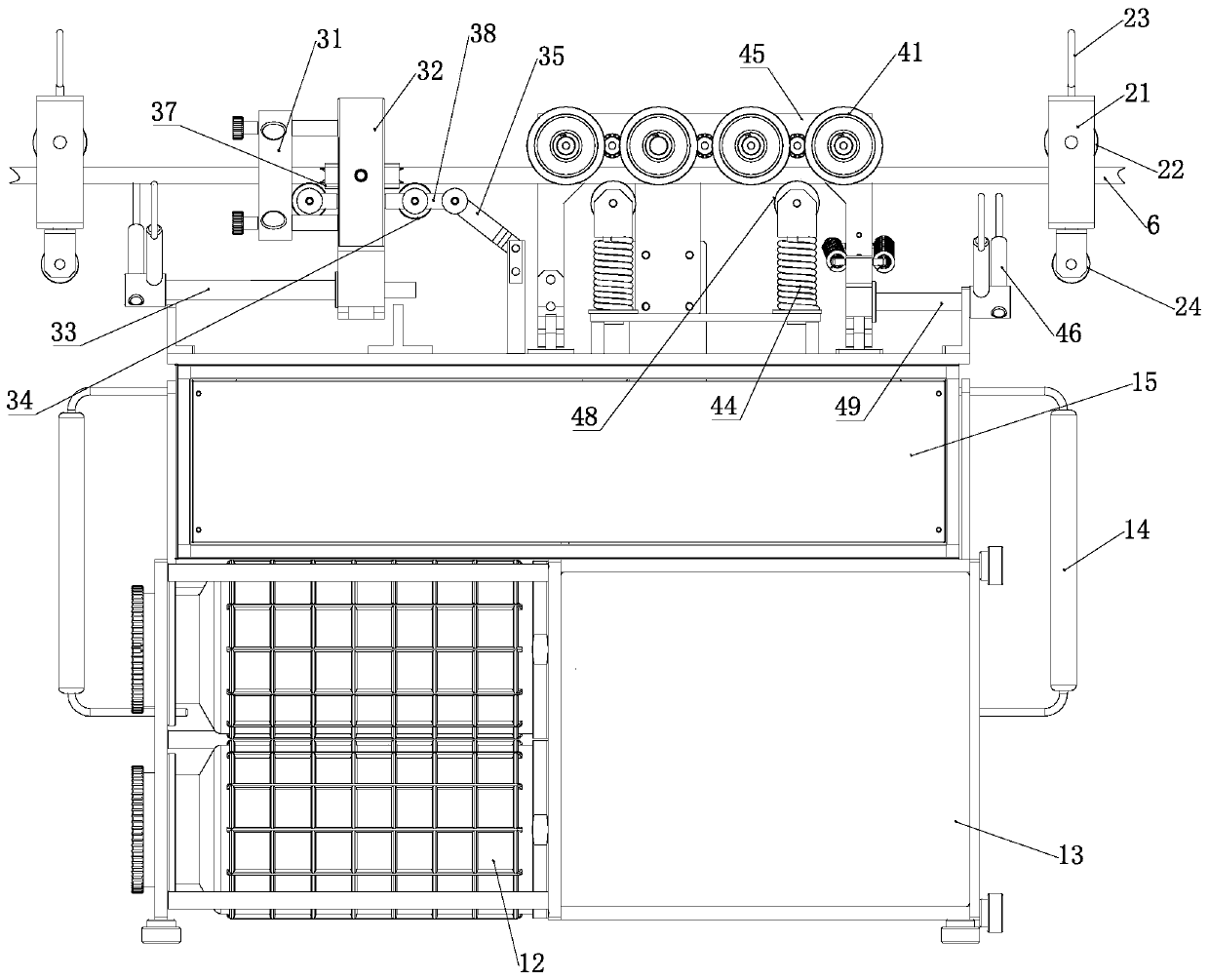

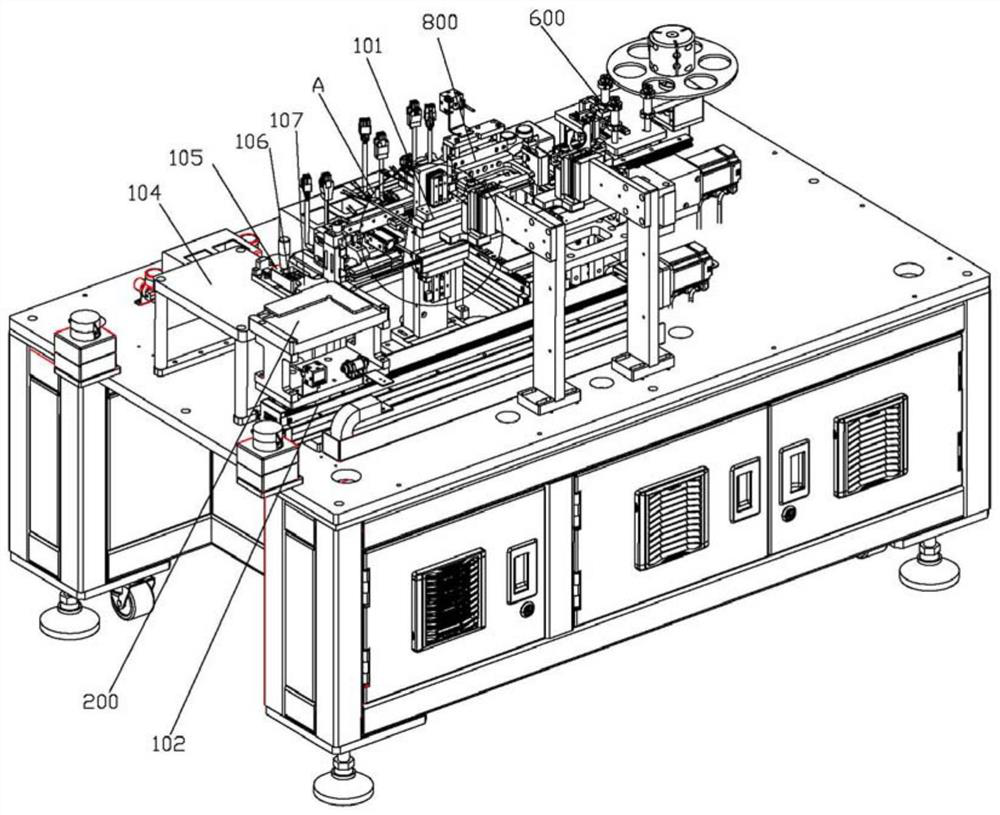

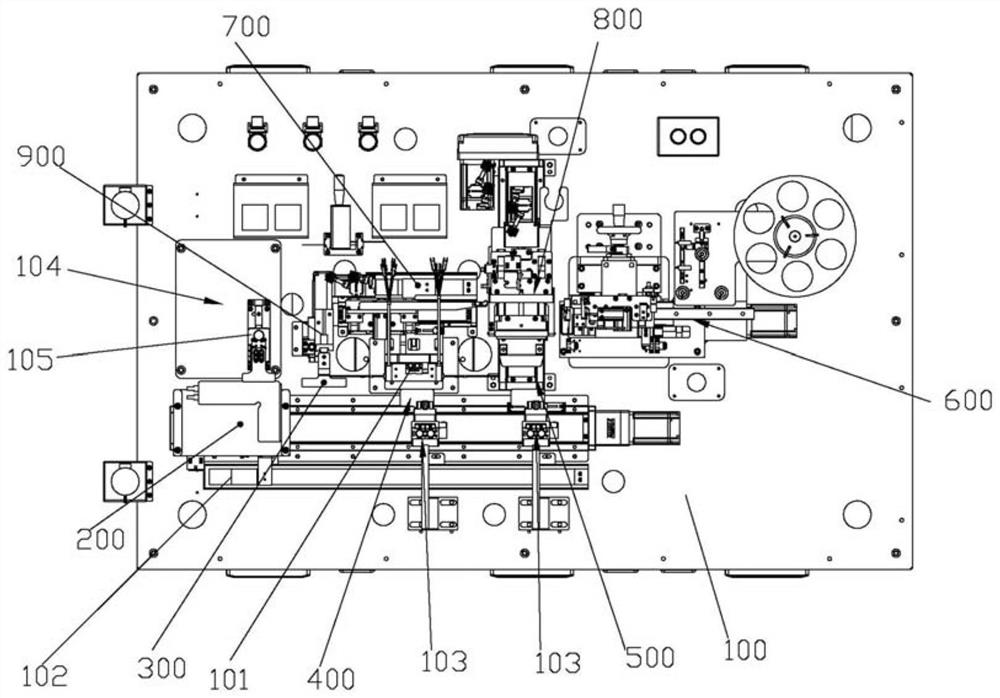

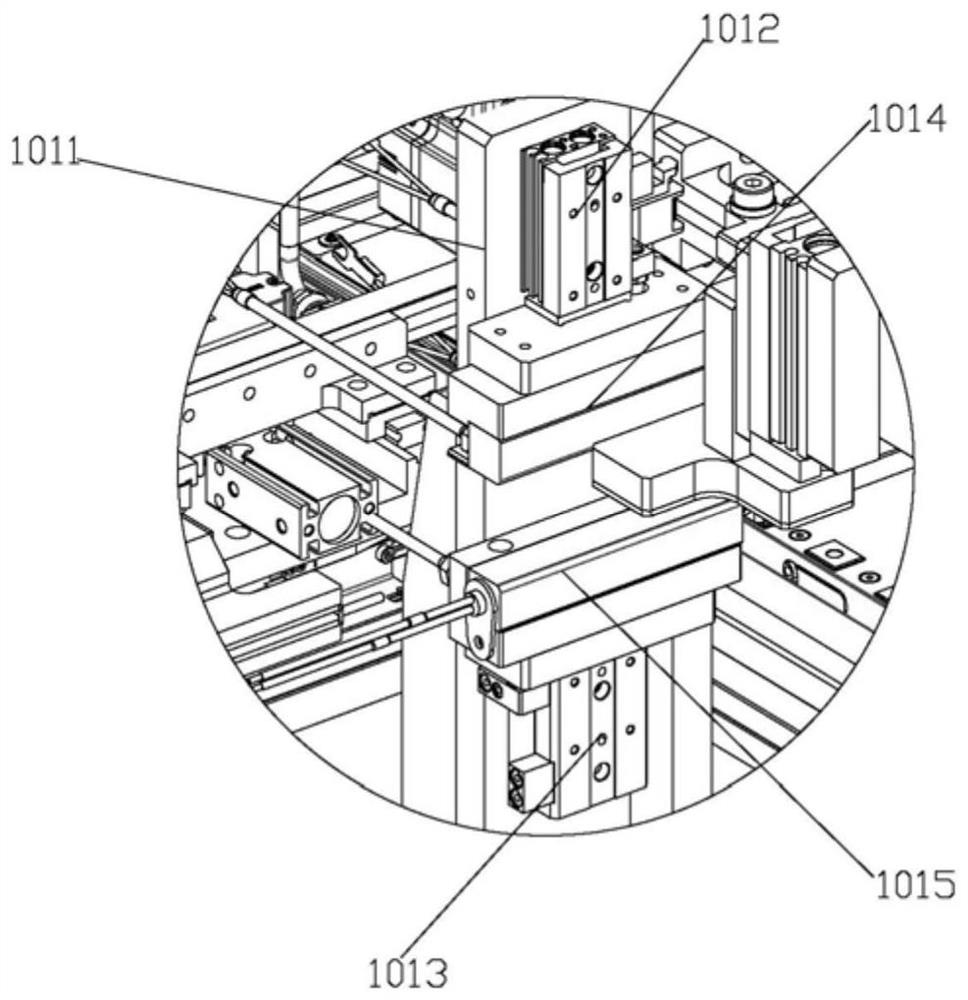

Automatic tape coating and cutting-off mechanism for RO (reverse osmosis) membrane

ActiveCN105435642AIncrease productivityGood lagging effectSemi-permeable membranesMembranesReverse osmosisEngineering

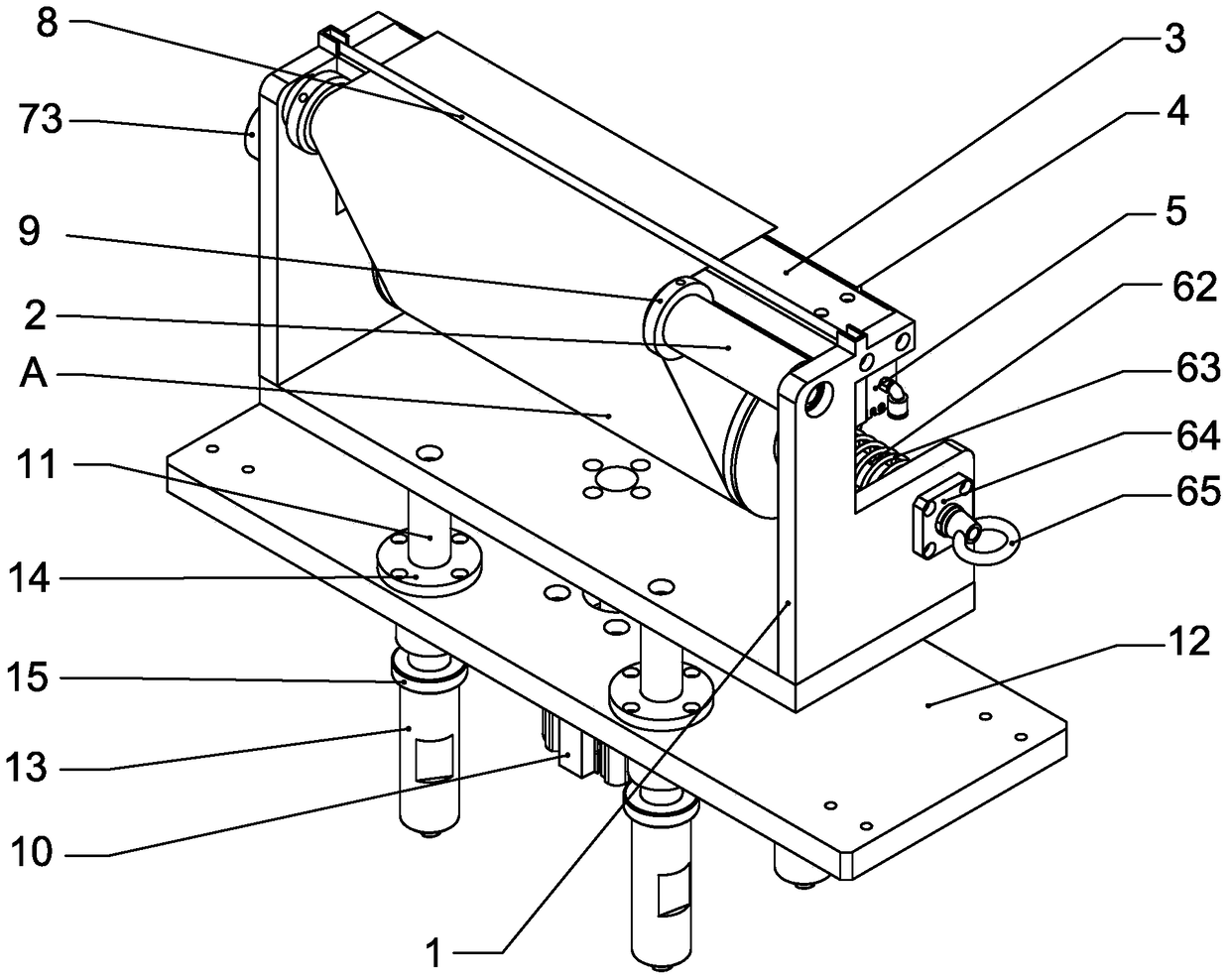

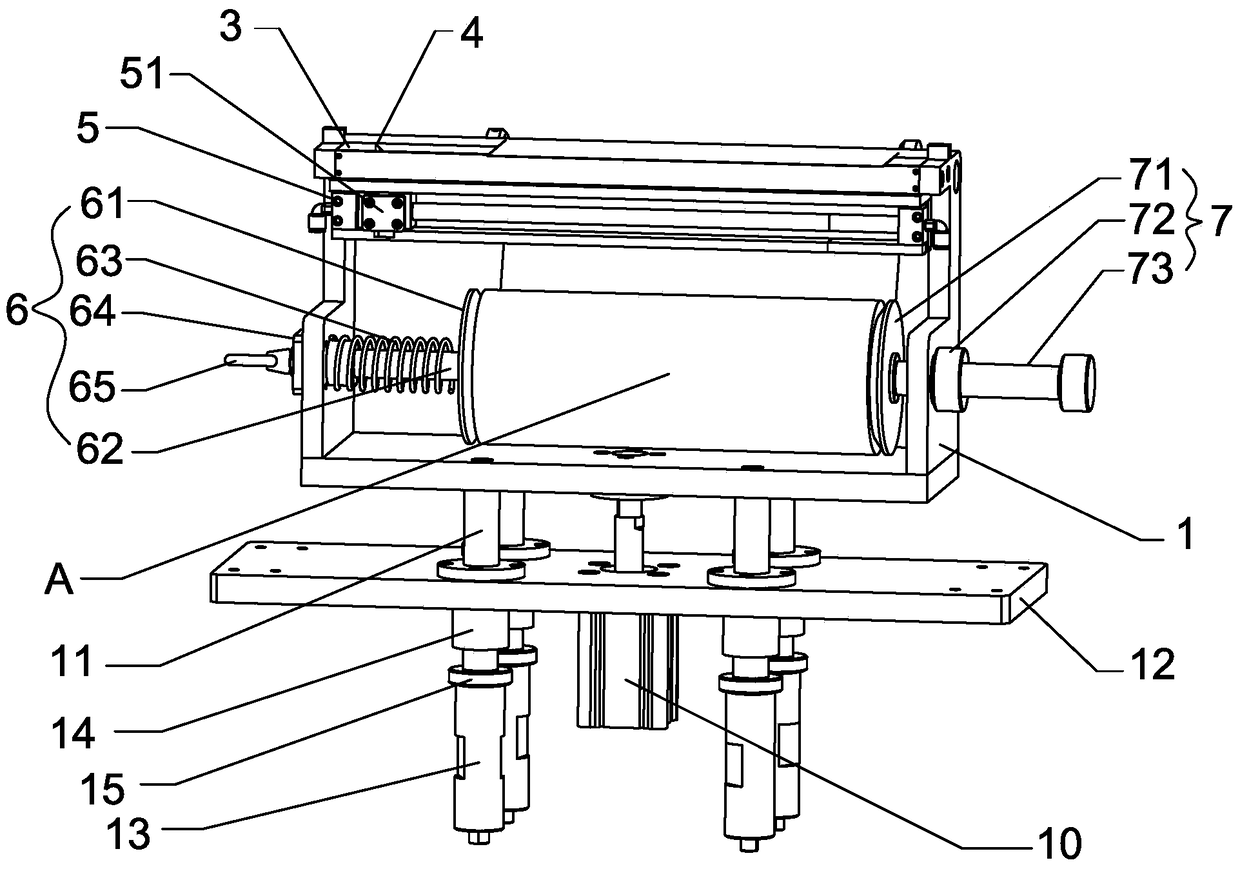

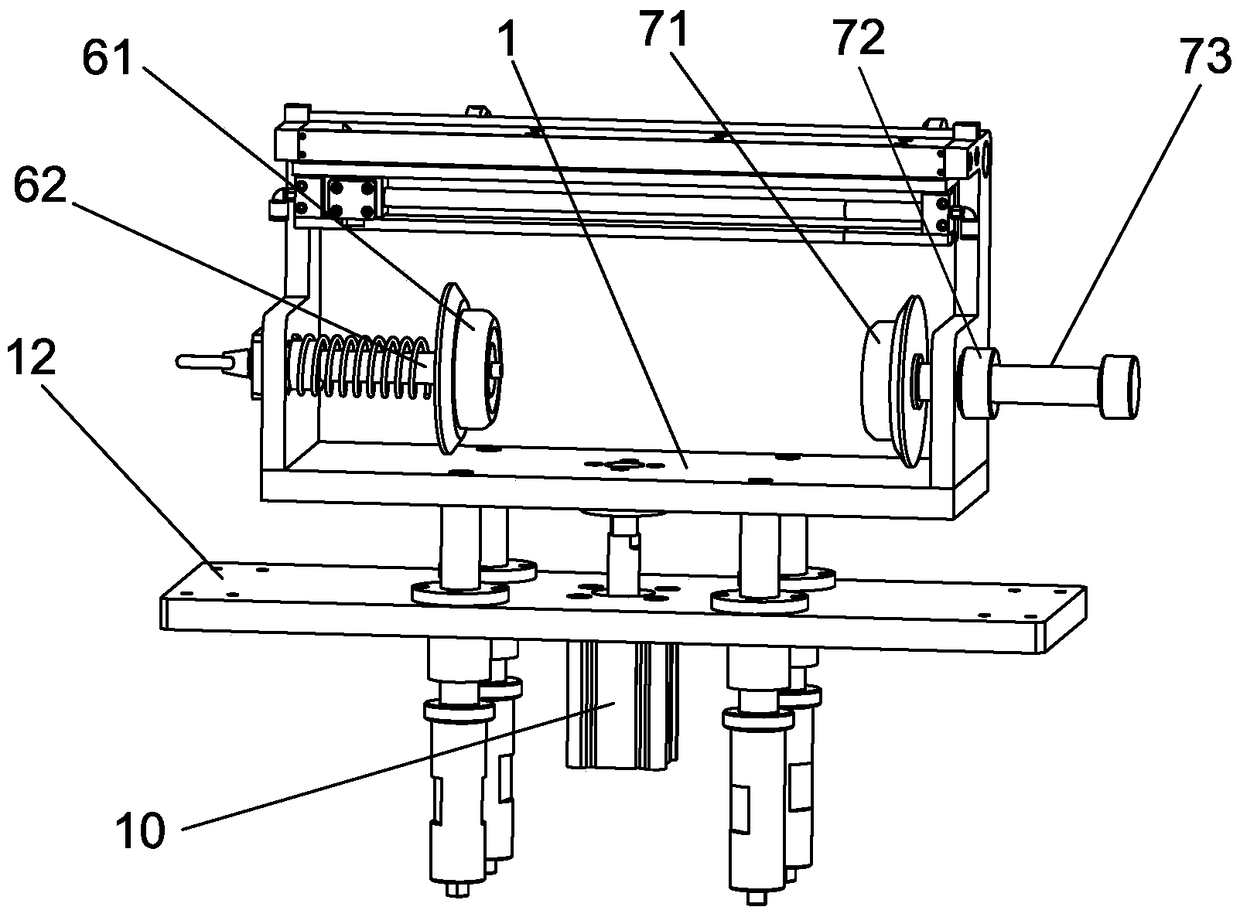

The invention applies to the technical field of RO (reverse osmosis) membrane production and provides an automatic tape coating and cutting-off mechanism for an RO membrane. The automatic tape coating and cutting-off mechanism comprises a tape winding bracket, an adhesive tape sliding shaft for guiding an adhesive tape, adhesive tape sleeve joint assemblies for sleeve joint of a wound adhesive tape material, an adhesive tape adsorption bottom plate, a tape cutting blade and a sliding cylinder, wherein the adhesive tape sliding shaft, the adhesive tape sleeve joint assemblies, the adhesive tape adsorption bottom plate and the sliding cylinder are all mounted on the tape winding bracket; the adhesive tape sleeve joint assemblies are located below the adhesive tape sliding shaft; the adhesive tape adsorption bottom plate is horizontally arranged on one side of the adhesive tape sliding shaft; the sliding cylinder is fixed below the adhesive tape adsorption bottom plate; the tape cutting blade is fixedly connected onto a sliding base of the sliding cylinder and extends out of the upper surface of the adhesive tape adsorption bottom plate. The wound adhesive tape material in sleeve joint on the adhesive tape sleeve joint assemblies is automatically wound and pulled and coats the rotating RO membrane, and the tape cutting blade cuts off the tape after the tape coating is finished. The automatic tape coating and cutting-off mechanism has the advantages of low production cost, high production efficiency and excellent tape coating effect.

Owner:SHENZHEN SECOND INTELLIGENT EQUIP CO LTD

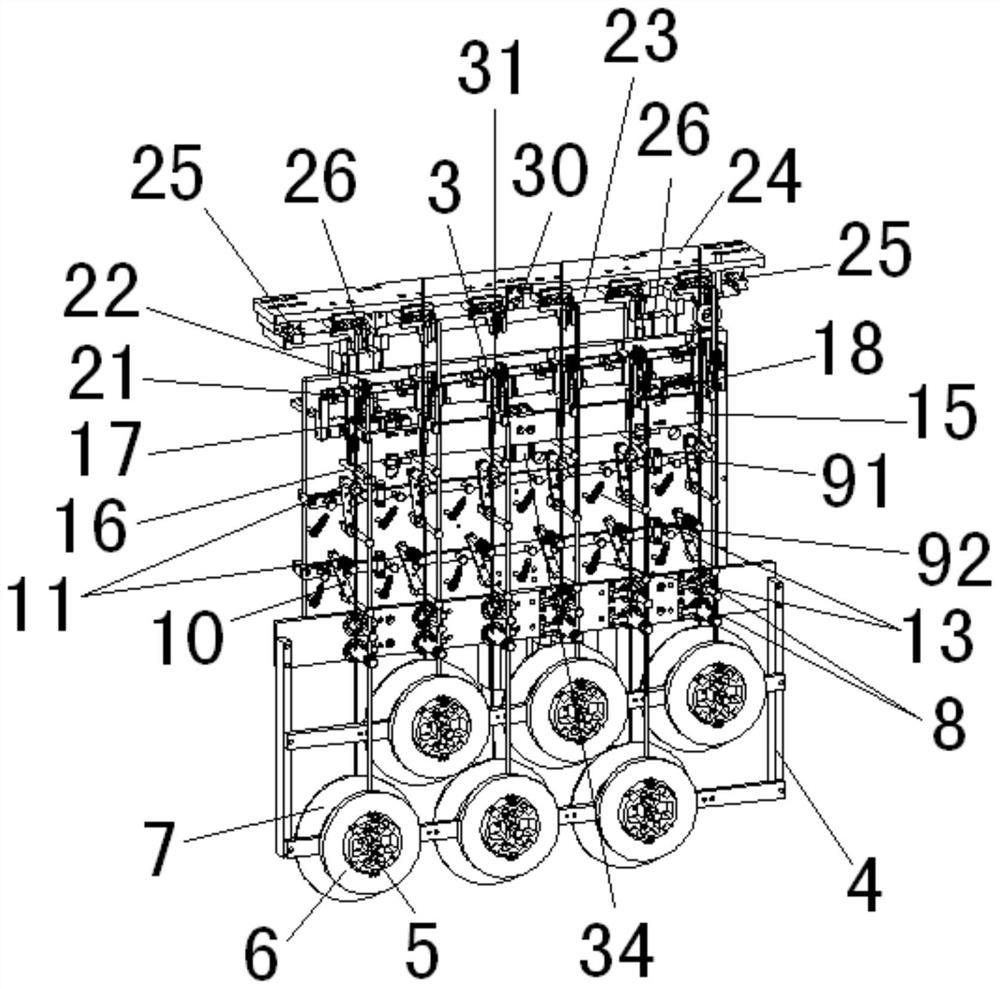

High-voltage charged overhead bare wire intelligent rubber-coated spraying robot

ActiveCN109768498AImproved fixation and laggingImprove lagging effectLiquid surface applicatorsCoatingsEngineeringInjection pressure

The invention belongs to the technical field of electric power systems, and relates to a high-voltage charged overhead bare wire intelligent rubber-coated spraying robot. A glue injection device comprises an opening-shaped fixing seat, clamping arms fixedly mounted on both sides of the fixing seat and an injection pressure ring fixed connected to the clamping arms; a driven wheel and a plurality of second blocking wheels are respectively fixedly mounted on both outer sides of a blocking plate in a transmission device, a driving wheel is fixedly mounted on a rotating motor, a conveyor belt is installed between the driving wheel and the driven wheel, a plurality of meshing gears are evenly mounted between the two blocking plates, the second blocking wheels are fixedly connected to a rotatingshaft of the spaced gears, the driven wheel is fixedly connected with one of the gears through the rotating shaft, a cabinet below the second blocking wheels is fixedly mounted with a plurality of limit posts, and the lower portion of the blocking plates is fixedly connected with an opening-shaped base. The high-voltage charged overhead bare wire intelligent rubber-coated spraying robot solves the problem in the prior art that injecting an insulating layer robot has a poor fixing effect on bare wires, resulting in poor rubber coating effect of the bare wires and easy electric leakage.

Owner:重庆洎皋电力科技有限责任公司

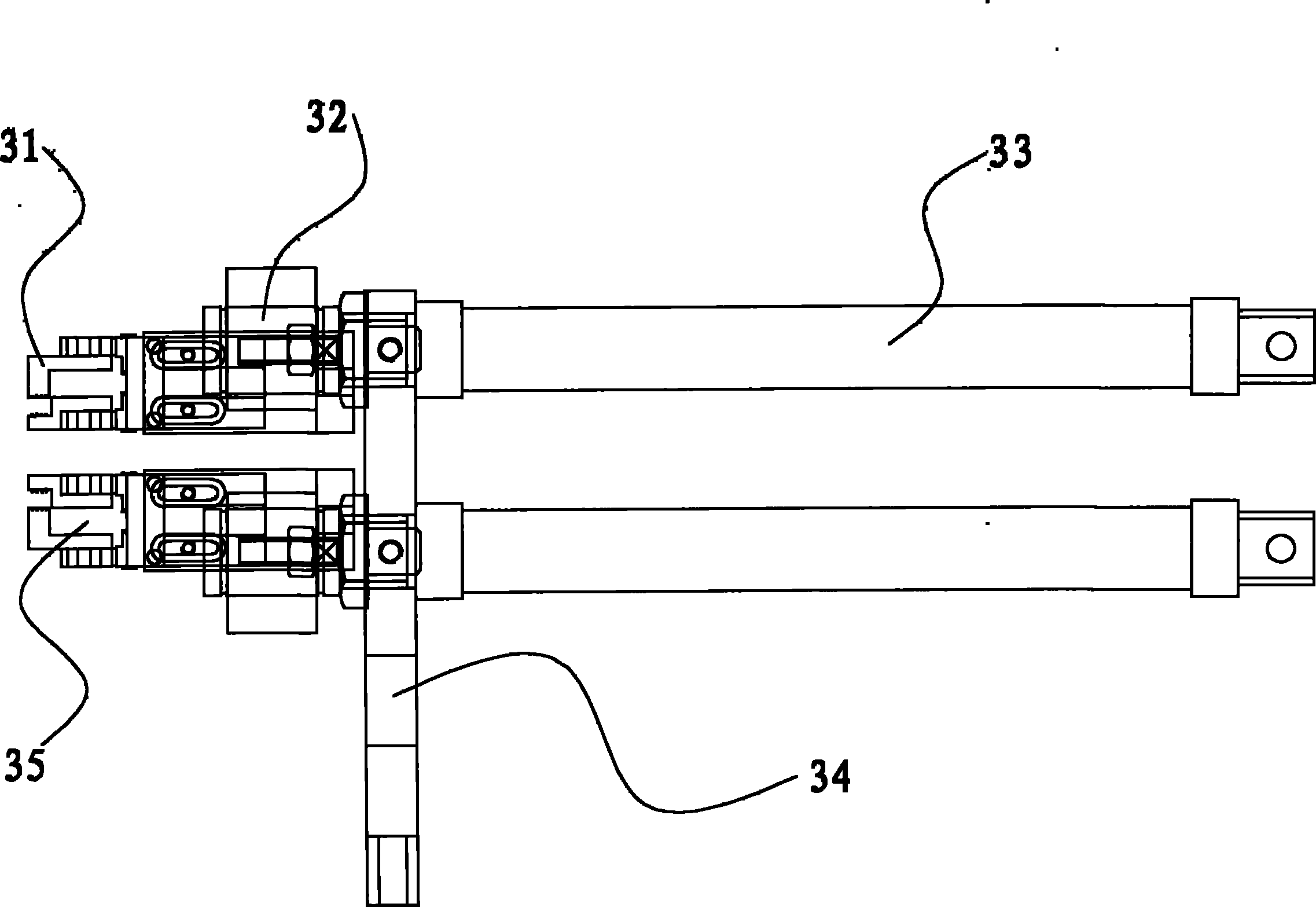

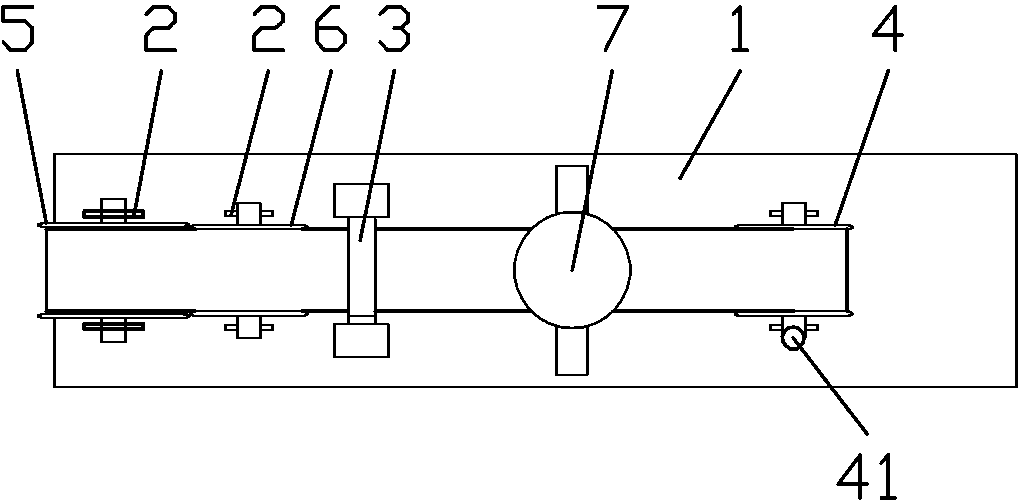

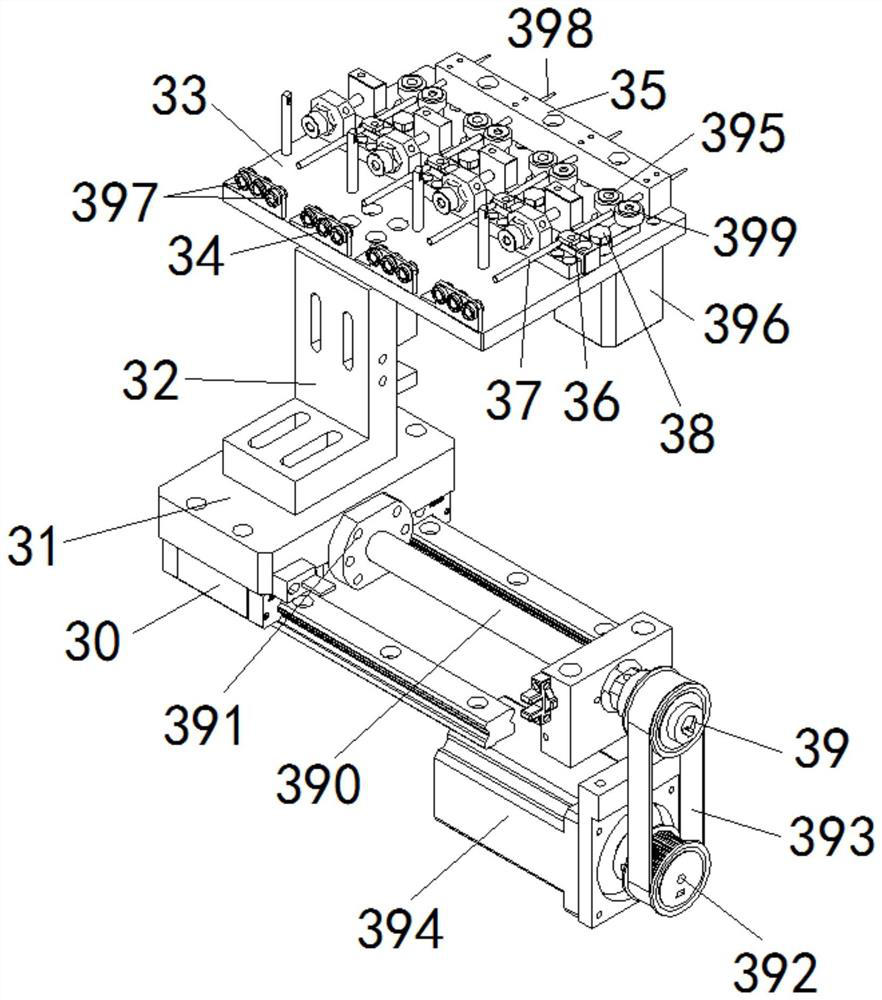

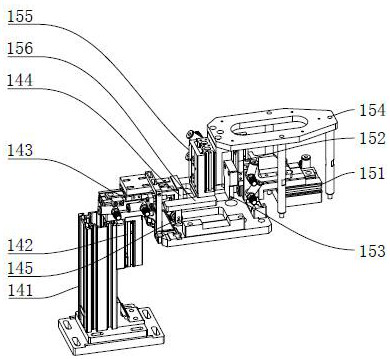

Automatic adhesive feeding device for tabs

InactiveCN102738431AConsistent performanceGood lagging effectCell component detailsManipulatorEngineering

An automatic adhesive feeding device for tabs mainly comprises an adhesive tape pressing mechanism, an adhesive tape cutting mechanism and an adhesive tape clamping mechanism. The adhesive tape pressing mechanism is fastened on a table panel. The adhesive tape cutting mechanism and the adhesive tape clamping mechanism are both fixed on an engine base. Automatic adhesive feeding is conducted through clamping fingers of a manipulator, thus truly achieving automatic adhesive wrapping of adhesive tapes for tabs. Simultaneously, through synchronous operation of the adhesive cutting mechanism, properties of tabs manufactured are consistent. In addition, the adhesive wrapping effect is good, the defect rate is greatly reduced, and simultaneously the tab wrapping production efficiency is raised.

Owner:XIAMEN XINTAIBO TECH

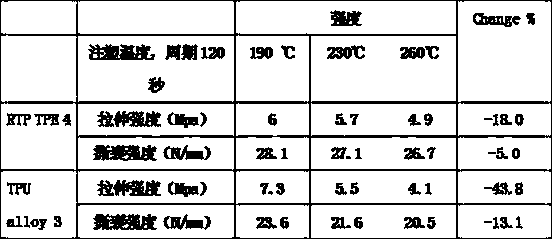

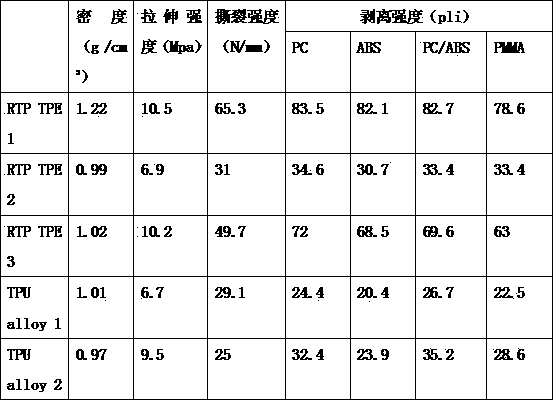

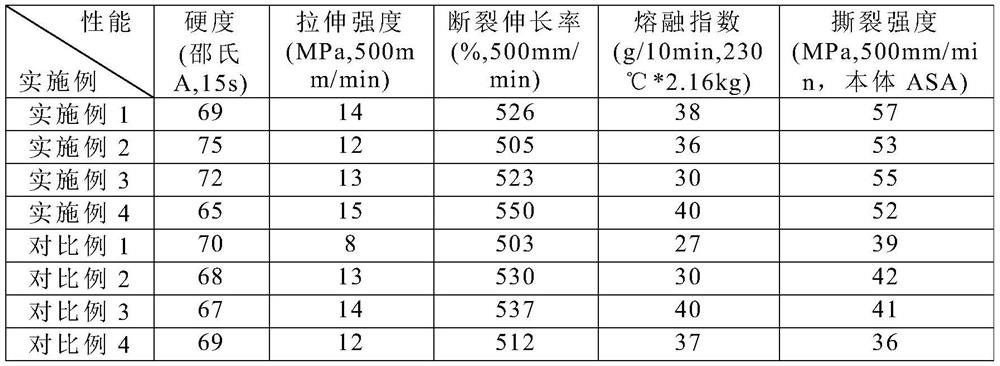

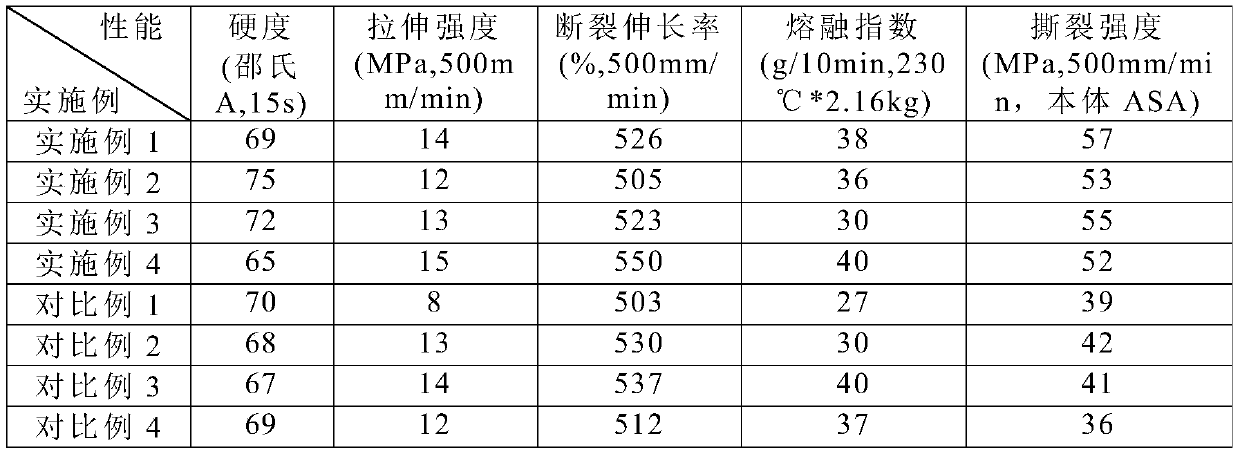

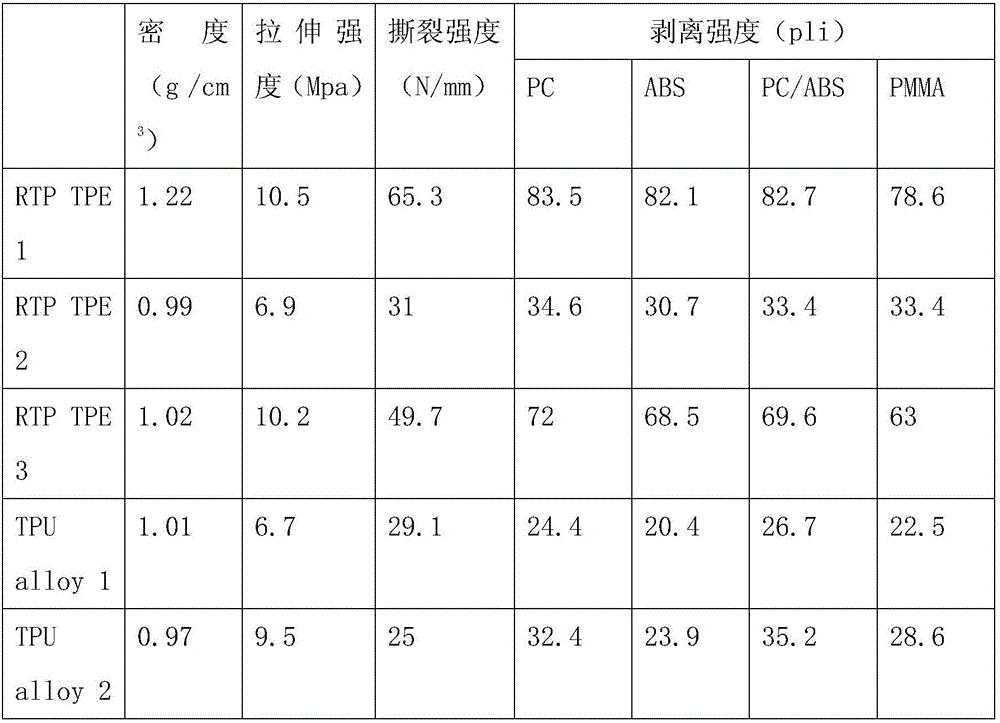

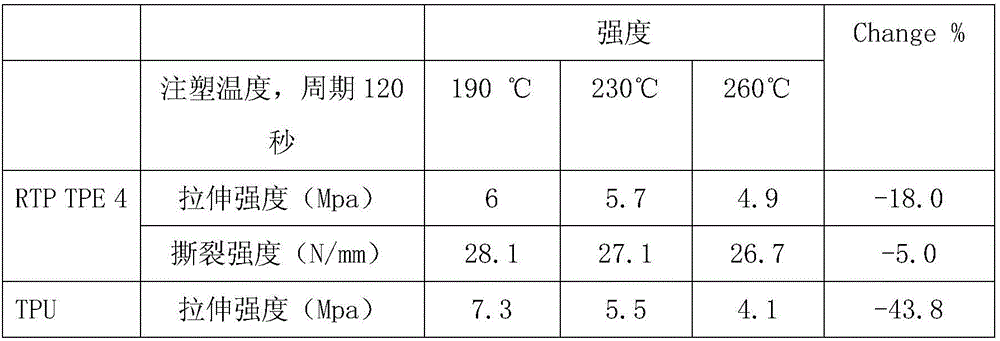

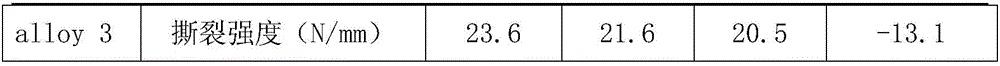

High-performance thermoplastic elastomer and processing method thereof

The invention provides a high-performance thermoplastic elastomer and a processing method thereof. The high-performance thermoplastic elastomer comprises the following components in parts by weight: 20-100 parts of polyether elastomer TPEE, 0-70 parts of styrene elastomer, 0-30 parts of maleic anhydride-grafted SEBS, 0-50 parts of rubber filling oil, 0-40 parts of mineral powder and 0-5 parts of a stabilizer. The thermoplastic elastomer with high strength and stable performance can be produced by virtue of different raw materials and proportions; a processing process temperature (190-260 DEG C) of the high-performance thermoplastic elastomer is wider in range in comparison with that of the conventional TPU (thermoplastic polyurethane) and an alloy product thereof. The adopted extruder screw head can be used for lowering the melt temperature, lowering the material decomposition and promoting the materials to uniformly mix, so that obtained high-performance thermoplastic elastomer is high in strength, stable in performance, excellent in weather resistance and yellowing resistance, and excellent in rubber coating effect.

Owner:安特普工程塑料(苏州)有限公司

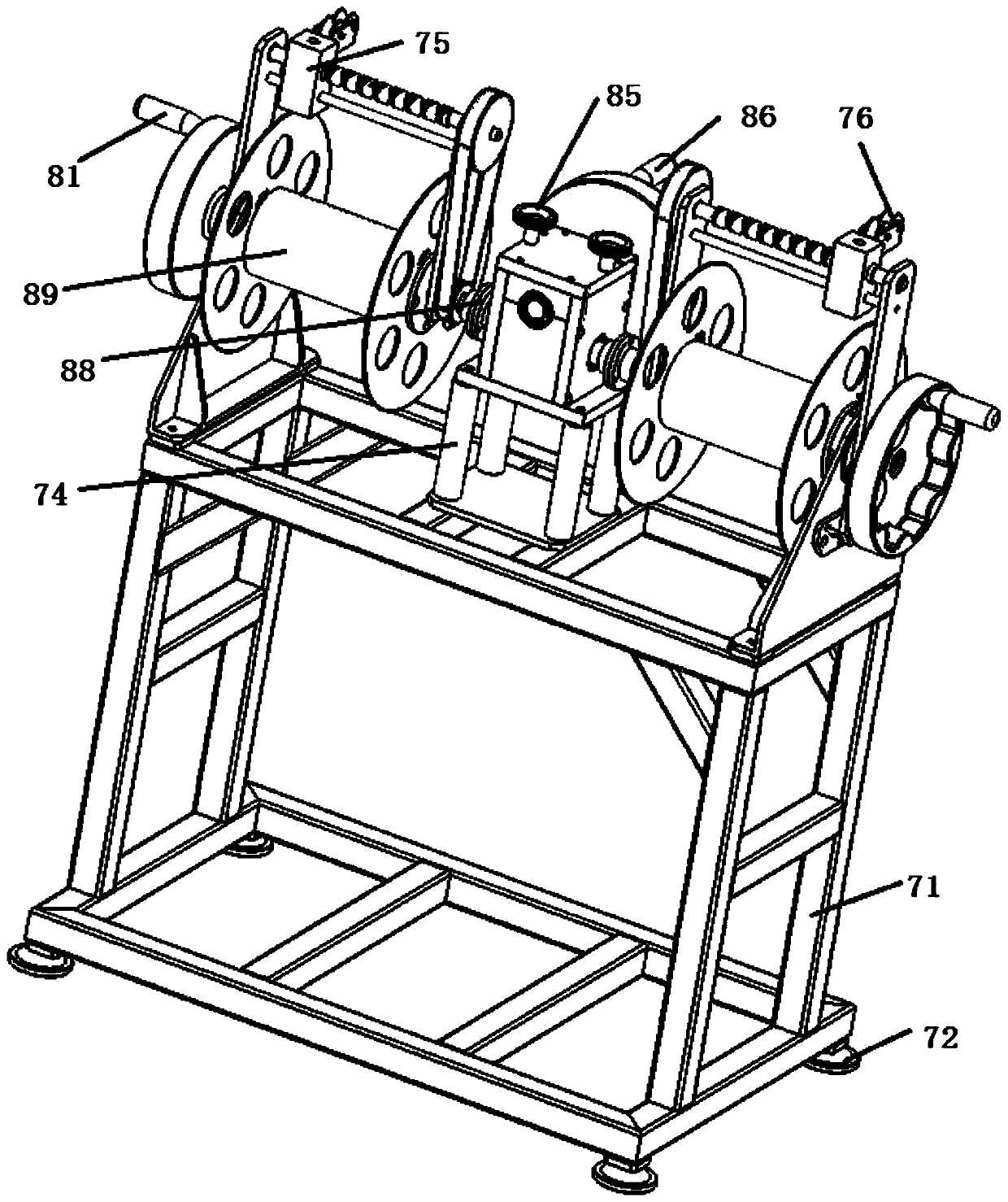

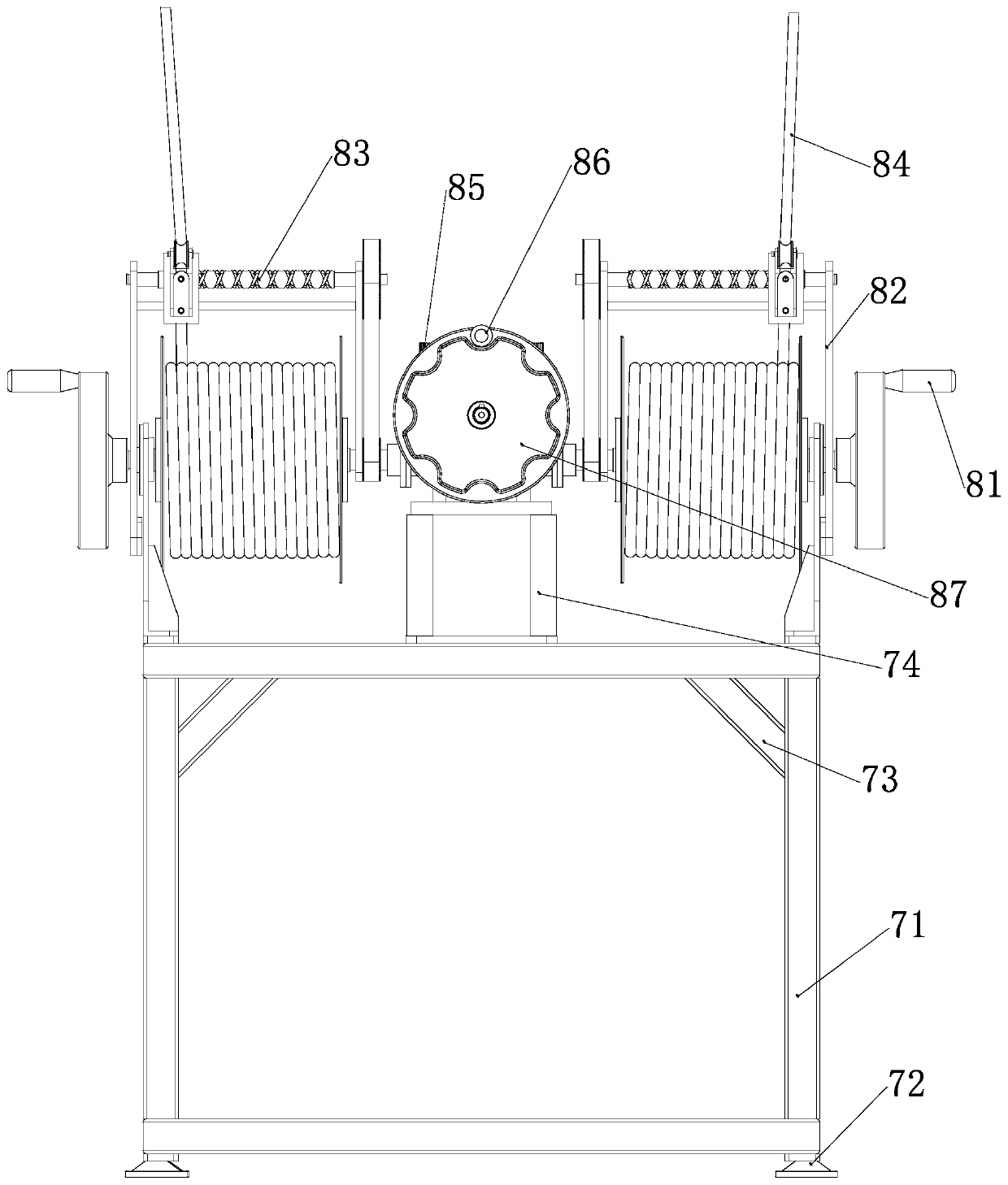

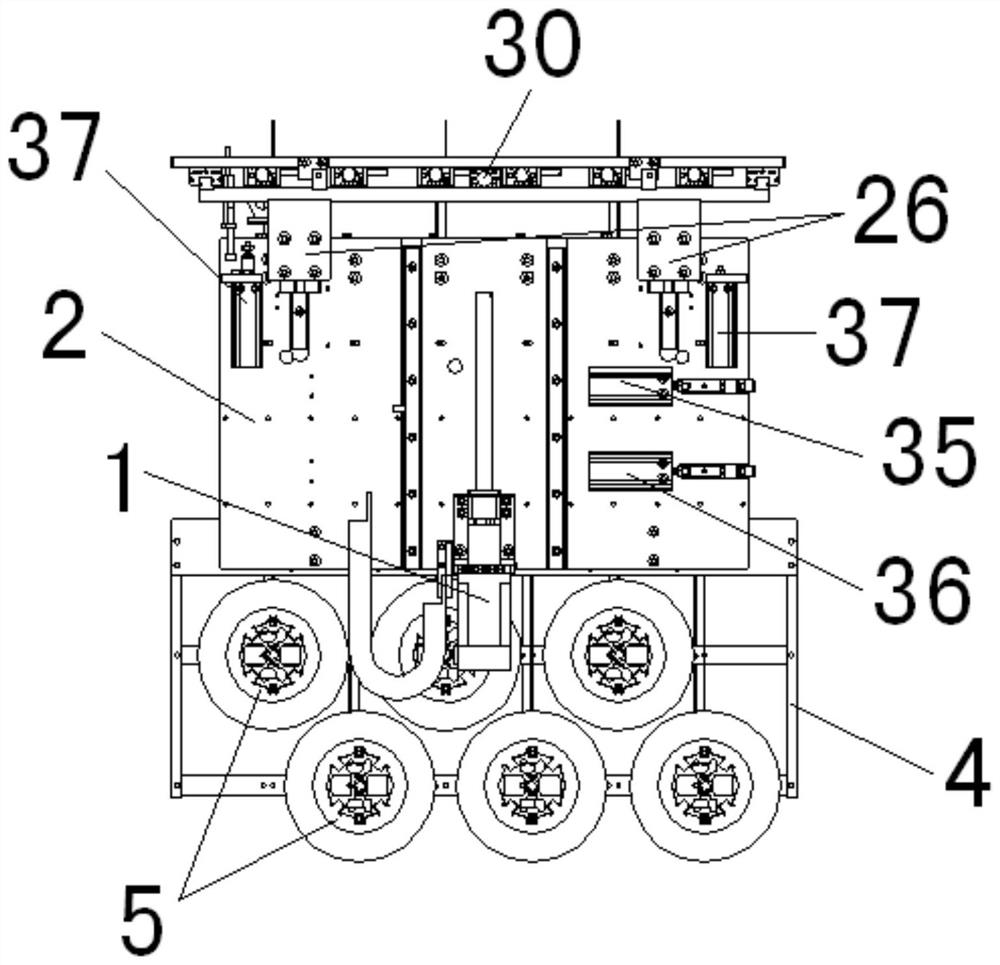

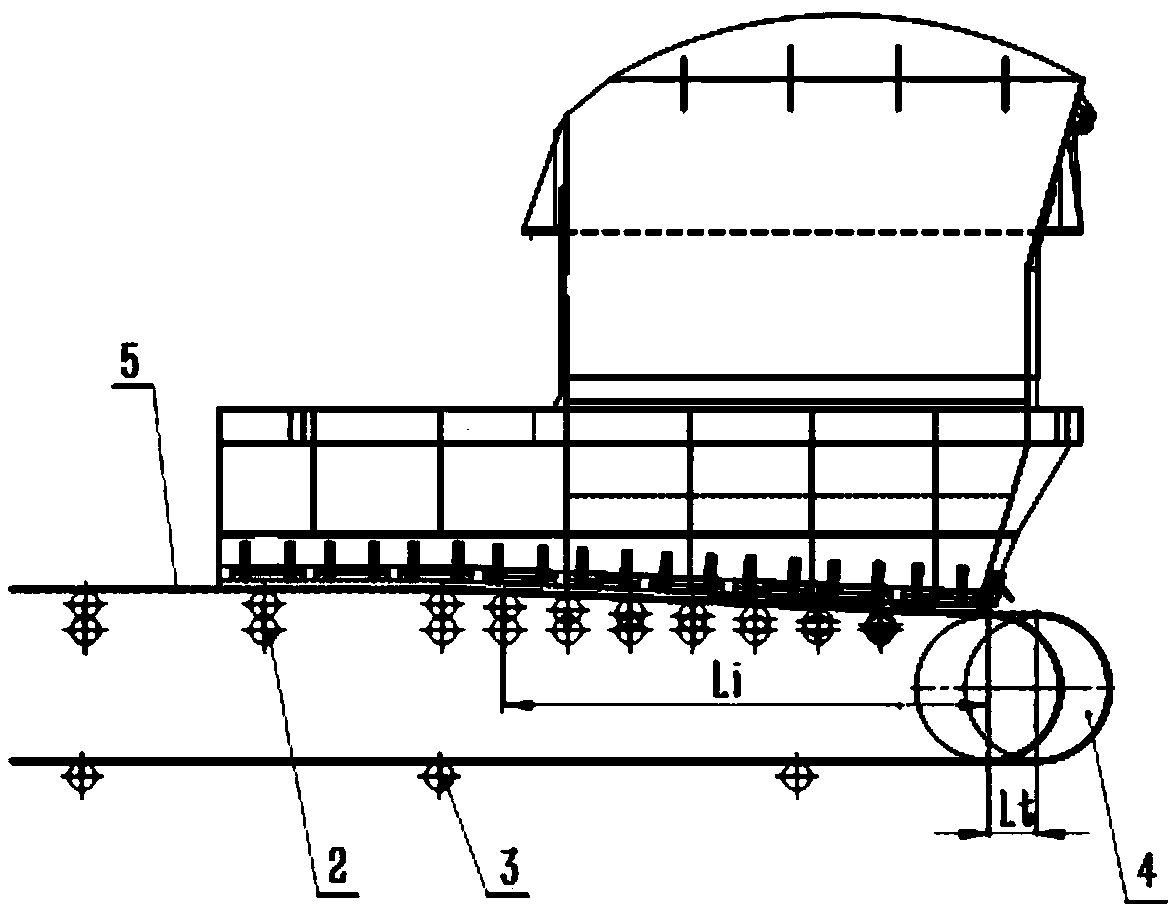

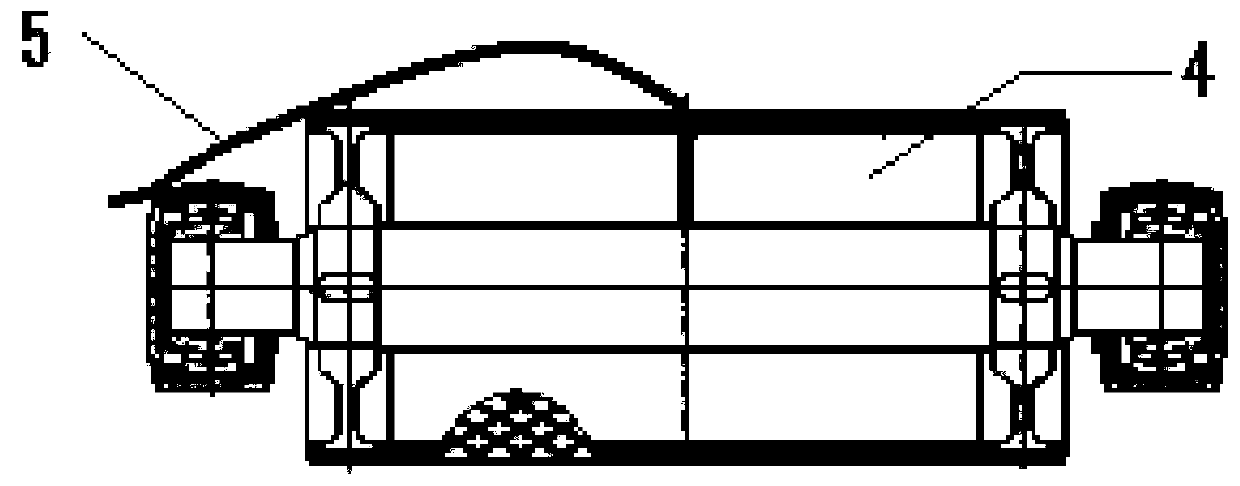

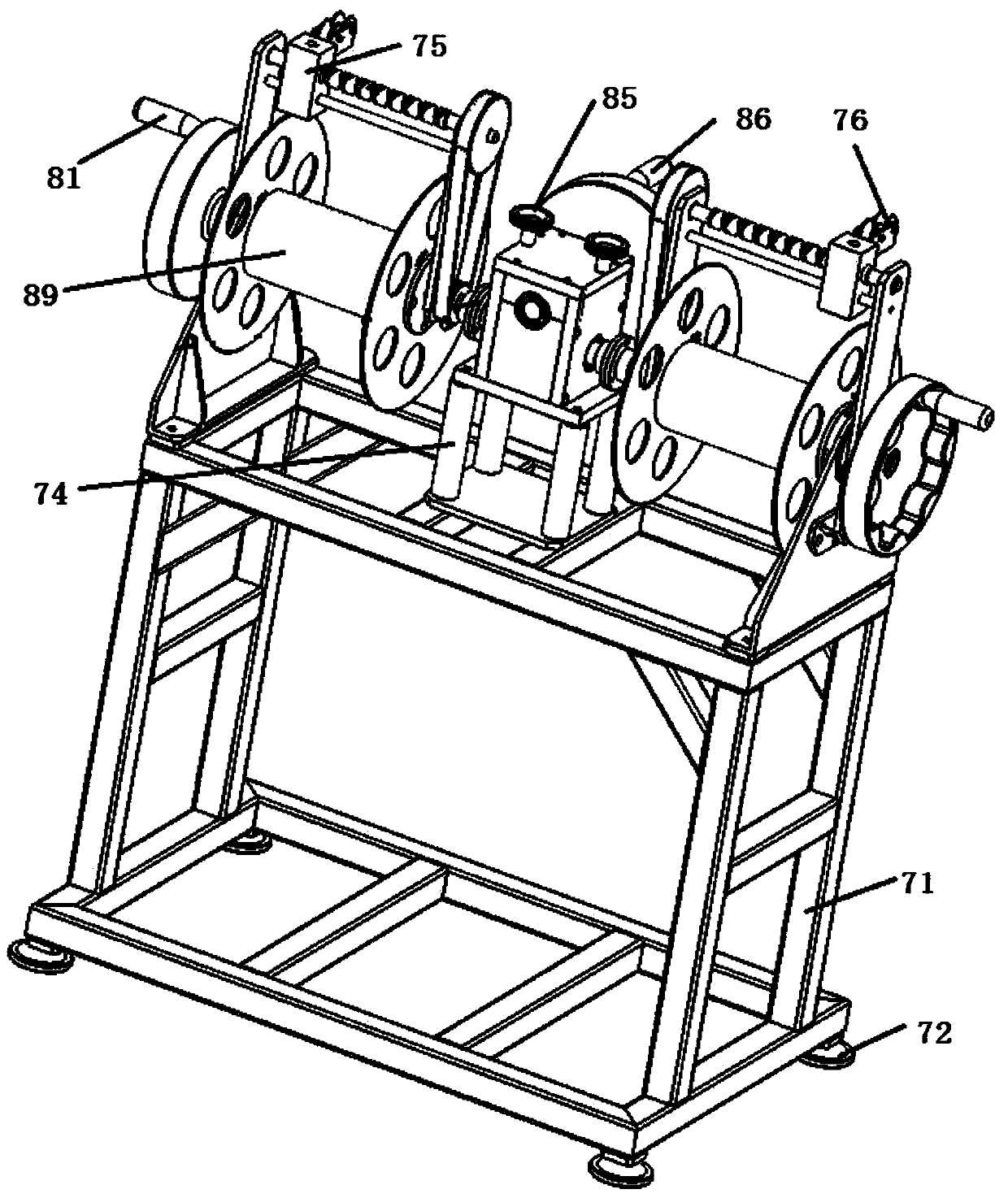

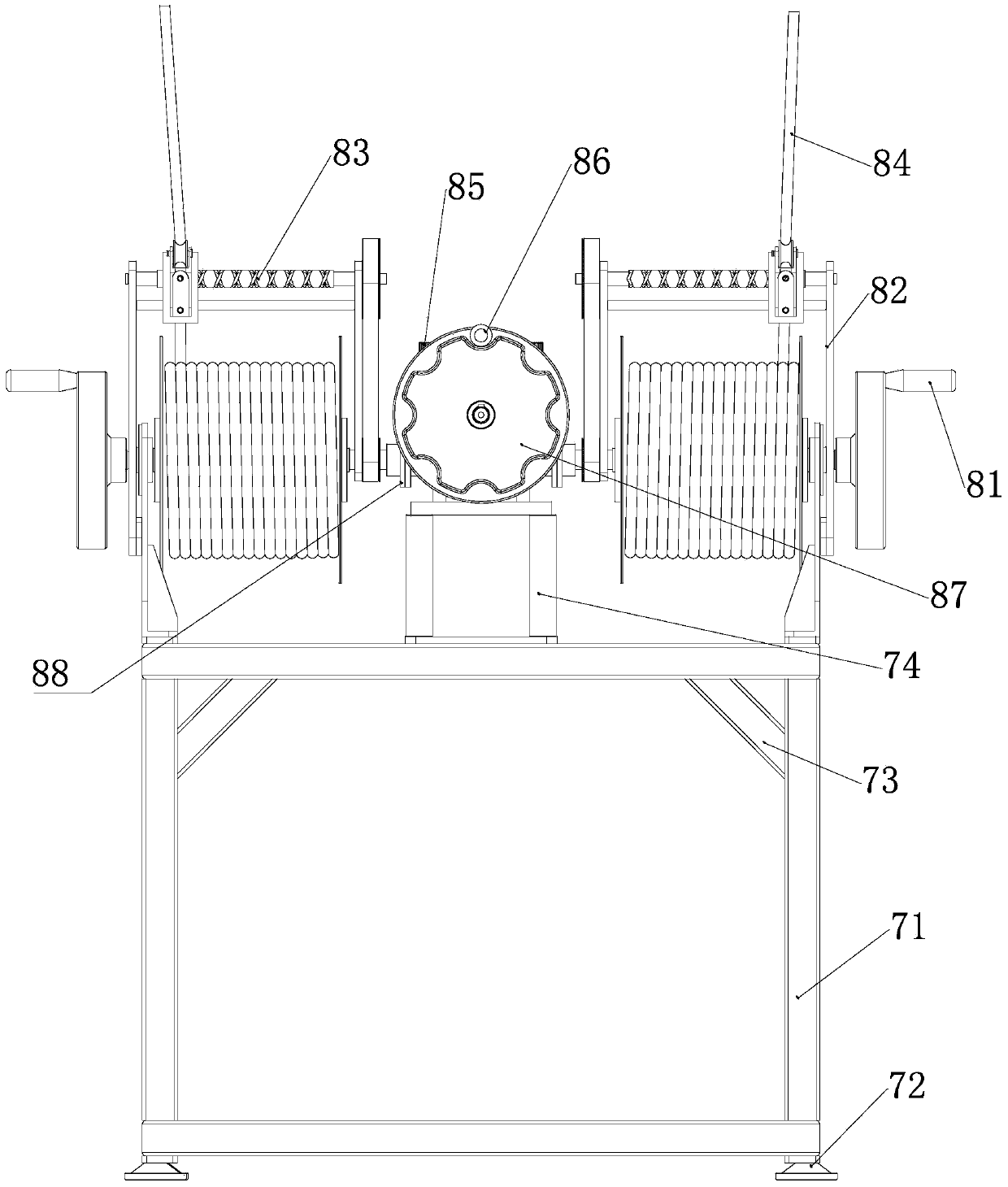

High-voltage electrified aerial bare conducting wire lifting crane and rubber coating spray painting robot thereof

ActiveCN109704220AEasy to operateThere is no potential safety hazard of electromagnetic interferenceLiquid surface applicatorsWinding mechanismsWire speedPaint robot

The invention belongs to the technical field of electric power systems, and relates to a high-voltage electrified aerial bare conducting wire lifting crane and a rubber coating spray painting robot ofthe high-voltage electrified aerial bare conducting wire lifting crane. A lifting device in the lifting crane comprises a wire speed adjusting device and wire winding devices, wherein the wire speedadjusting device is installed in the middle of the upper end of a machine frame, and the wire winding devices are installed on the two sides of the wire speed adjusting device. The wire speed adjusting device comprises a supporting frame, a worm and a worm wheel, wherein the supporting frame is installed on the machine frame, the worm is arranged on the supporting frame, and the worm wheel mesheswith the worm. A second hand wheel is fixedly installed on the outer side of the worm wheel, and a plurality of third hand wheels are evenly and fixedly installed on the upper side of the worm wheel.Each wire winding device comprises a wire winding roller, a guide rod and a first hand wheel. The wire winding rollers are fixedly arranged at the free ends of the worm, the guide rods are fixedly arranged above the wire winding rollers, and the first hand wheels are installed on the outer sides of the wire winding rollers. Sliding blocks are arranged on the guide rod in a penetrative mode, and traction wheels are fixedly installed on the sliding blocks. Pull ropes which are used for lifting the rubber coating robot are wound around the wire winding rollers, and the free ends of the pull ropespass through the traction wheels. The problem that in the prior art, the potential safety hazard exists in the mode that an automatic spray painting robot is conveyed by a control system is solved.

Owner:重庆洎皋电力科技有限责任公司

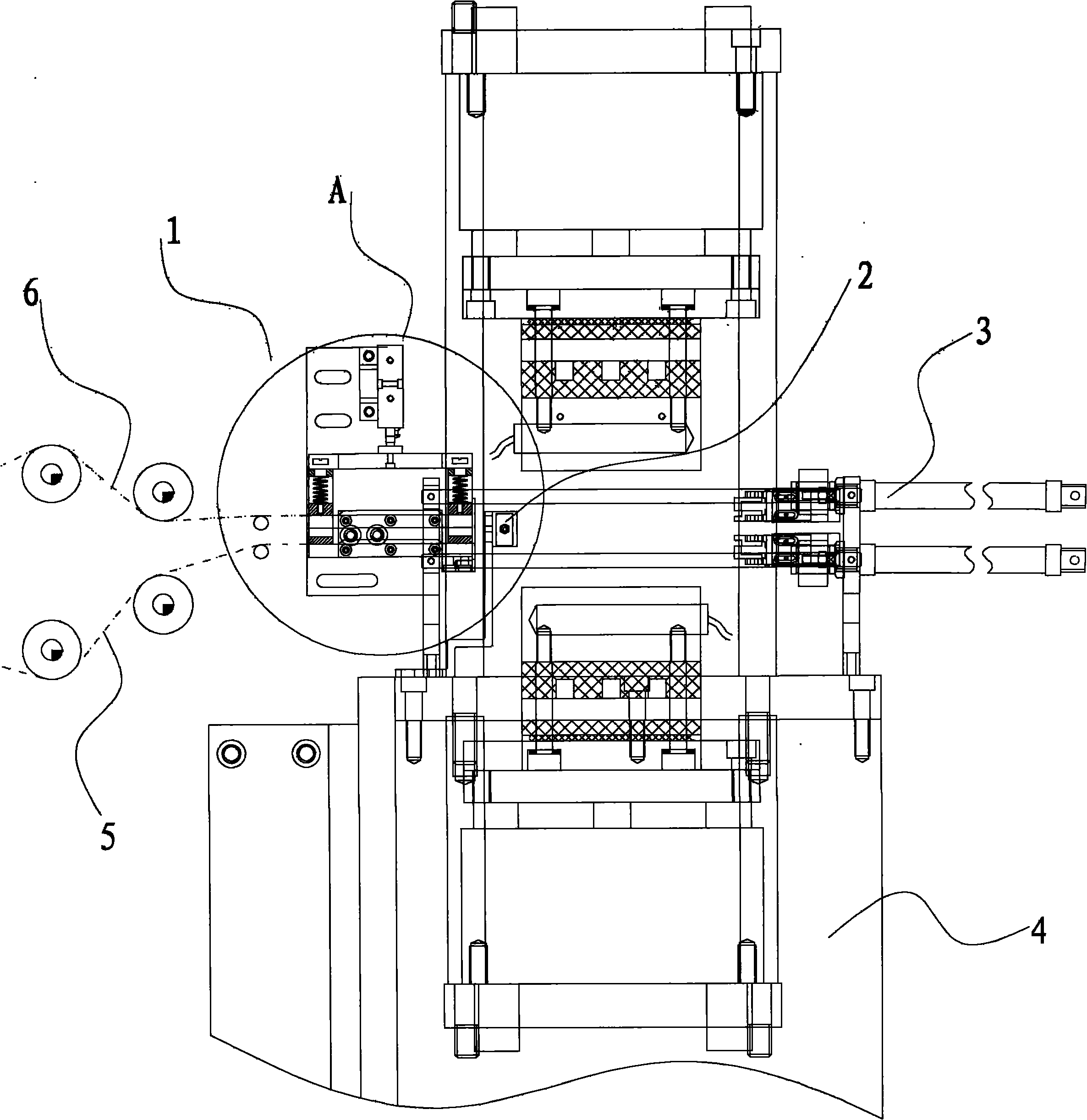

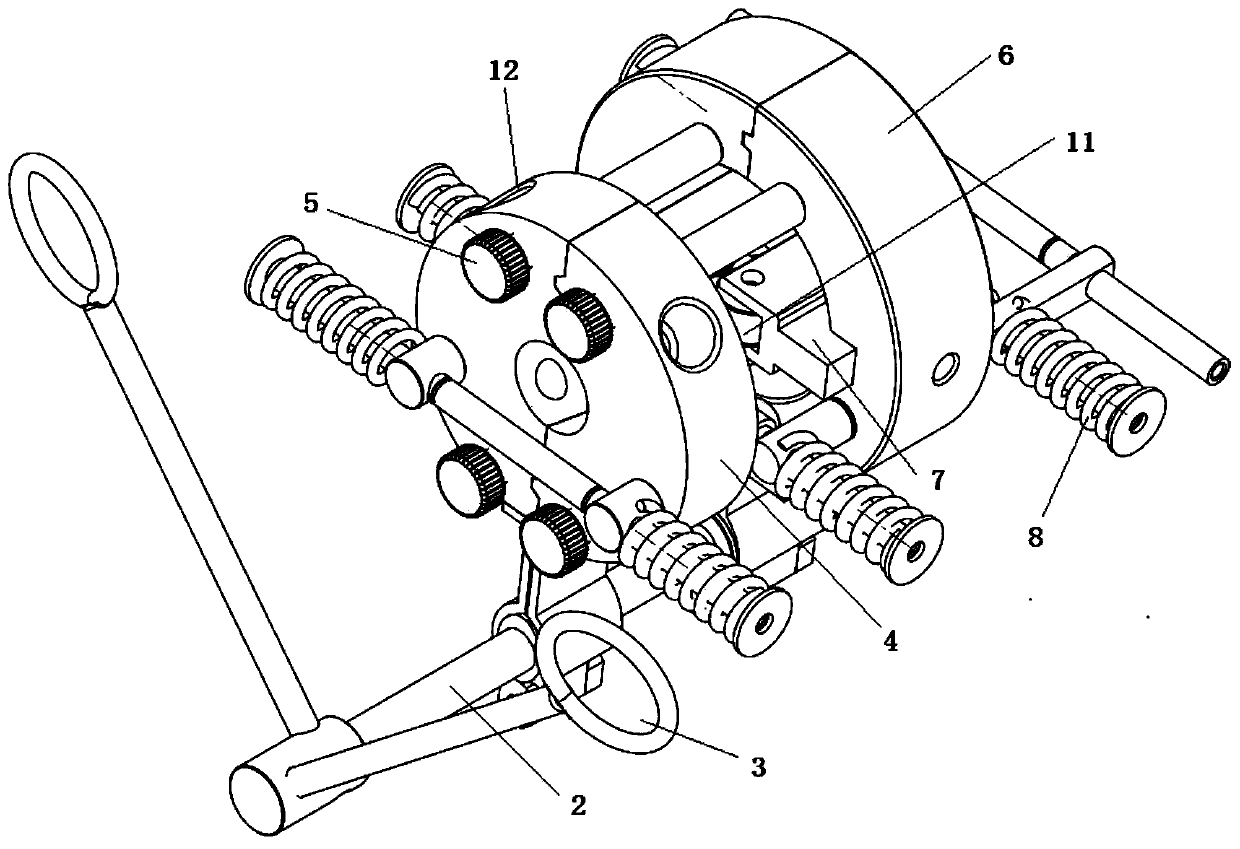

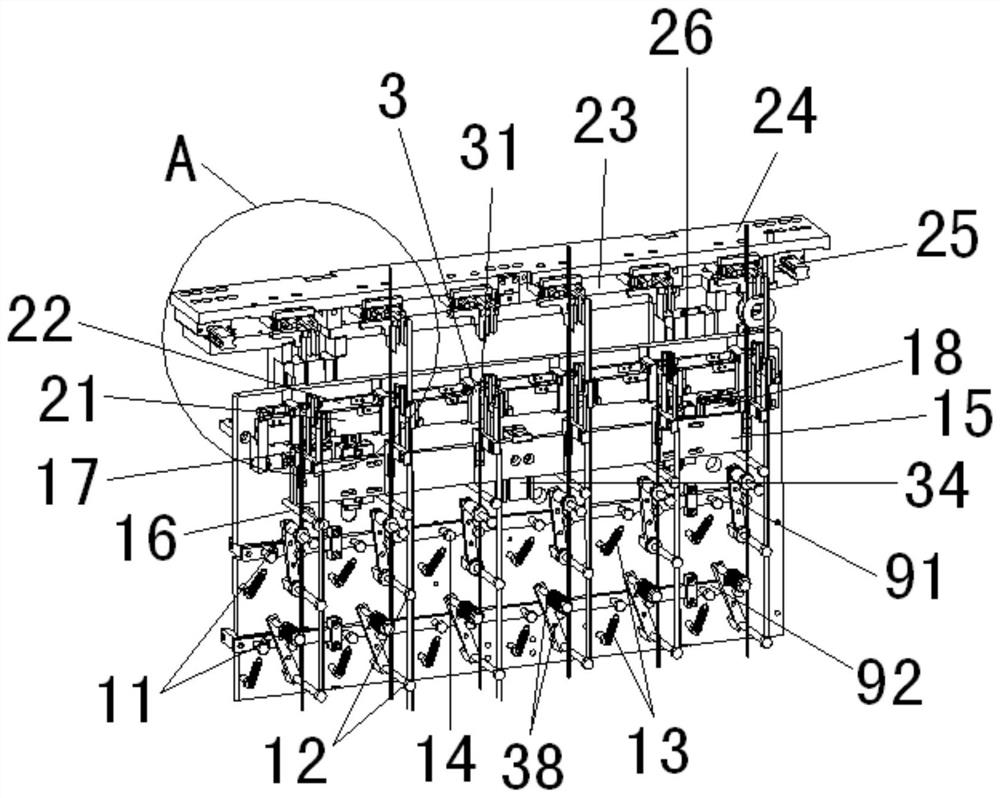

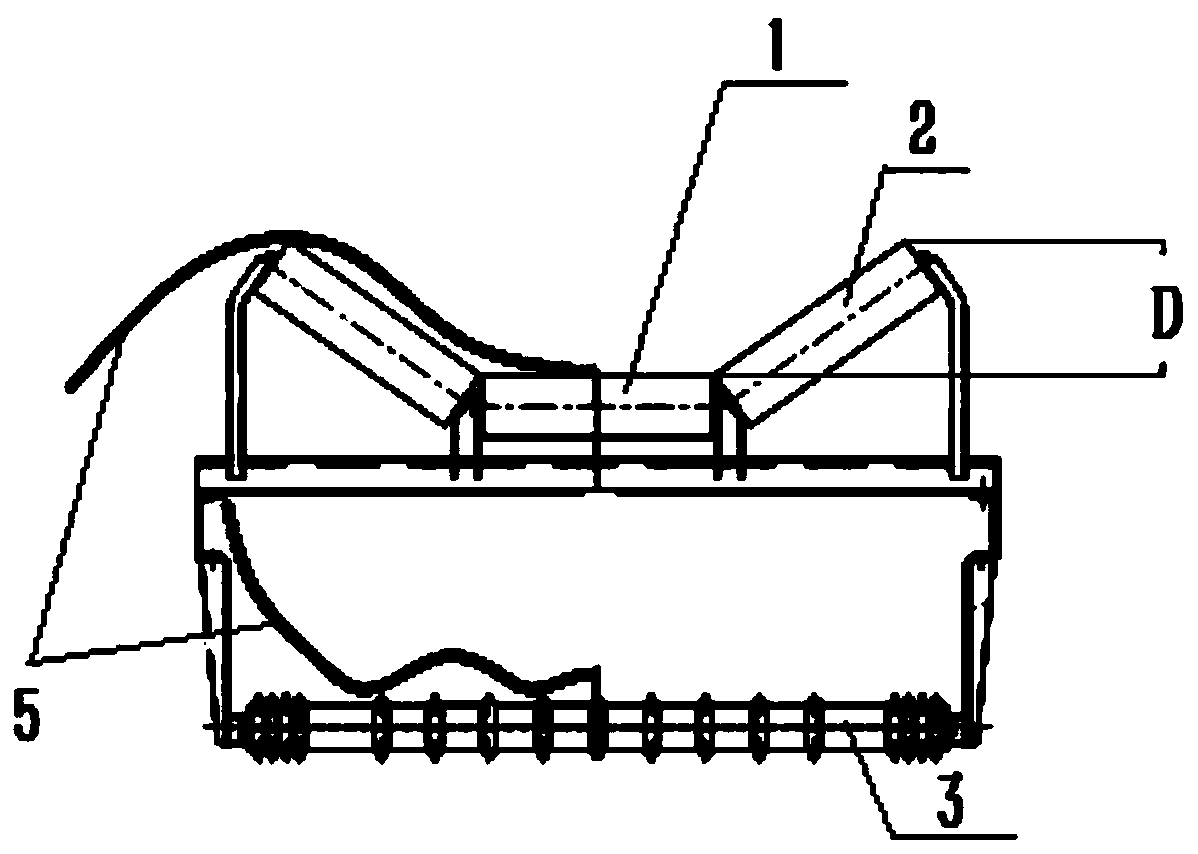

Automatic mold opening and closing mechanism for rubber coating and spraying of high-voltage electrified overhead bare conductor robot

PendingCN109638735AGood lagging effectElimination of climbing installation clamping device and glue injection deviceApparatus for repairing insulation/armouring cablesEngineeringMechanical engineering

The invention belongs to the technical field of power cables and relates to an automatic mold opening and closing mechanism for the rubber coating and spraying of a high-voltage electrified overhead bare conductor robot. The mechanism comprises a fixed base with a hinged lower portion and an opening-shaped upper portion, arc-shaped clamping arms fixedly installed on the two sides of the fixed base, and arc-shaped injection molding pressing rings fixedly connected with the clamping arms respectively. A plurality of injection molding holes are uniformly formed in the injection molding pressing rings. A through hole is formed in the middle of the fixed base. A cam is movably installed in the through hole. A connecting rod is fixedly installed on the cam. Two rocking handles are fixedly installed at the free end of the connecting rod. Clamping blocks with grooves formed in the middles thereof are fixedly installed on the inner sides of the clamping arms respectively. According to the invention, the problem that a cable fixing device in the prior art is not suitable for an operator to open, close and fix a bare conductor on the ground is solved.

Owner:重庆洎皋电力科技有限责任公司

Tape coating device

PendingCN109300677AReduce labor costsIncrease productivityEncapsulation/impregnationCoils manufactureMechanical engineeringCoating

The invention discloses a tape coating device, which is characterized by comprising a frame, a tape pulling mechanism arranged on the frame, a tape guiding mechanism and a tape cutting mechanism, andthe tape pulling mechanism is used for actively clamping the front end of the tape, so that the tape extends for a certain length along the tension direction of the tape pulling mechanism. When the front end of the tape passes through a device to be coated with the tape, the tension action is stopped, and after the tape is adhered to the device to be coated with the tape, the tape pulling mechanism stops the clamping action, and the tape guiding mechanism is arranged opposite to the tape pulling mechanism for guiding the tape and pressing the rear end of the tape after the device is coated with the tape, the tape cutting mechanism is used to cut off the device is coated with the tape and the tape guiding mechanism is presses the rear end of the tape. The device achieves automatic tape coating, saves labor cost and improves production efficiency, meanwhile, the tape coating effect is better.

Owner:珠海市日创工业自动化设备有限公司

Sleeve retaining wall rubber coating and winding all-in-one machine and winding process thereof

The invention discloses a sleeve retaining wall rubber coating and winding all-in-one machine, and the all-in-one machine comprises a rack, a retaining wall rubber coating all-in-one mechanism, a wirecutting mechanism, a winding main shaft, a winding guide pin part, a wire rod pipe penetrating mechanism, a tensioner, a feeding vibration disc, a main control screen, a feeding rail, a discharging mechanism, a Y-axis module, a Z-axis module and an X-axis module. By means of the overall structural design, a series of operations, such as sleeve feeding and conveying, wire feeding and conveying, retaining wall rubber belt feeding and conveying, insulating rubber belt feeding and conveying, framework feeding and conveying, framework retaining wall rubber belt rubber coating, framework winding feet, framework winding, framework secondary winding feet, framework thread end trimming, framework insulating rubber belt rubber coating, waste recycling and framework discharging, can be completed onone piece of equipment. The all-in-one machine has the advantages of being good in rubber coating effect, high in wire winding efficiency and good in wire winding effect, automatic connection feedingcan be achieved in the two adjacent procedures, and the problem that existing framework production equipment needs to feed materials between the two adjacent procedures manually can be solved.

Owner:苏州创易技研股份有限公司

Adhesive tape rotating disc winding machine of transformer adhesive tape packaging machine

InactiveCN103680910AFast windingThe winding process is convenient and fastInductances/transformers/magnets manufactureArticle deliveryWinding machineAdhesive belt

The invention belongs to the field of adhesive tape packaging of transformers, and particularly relates to an adhesive tape rotating disc winding machine of a transformer adhesive tape packaging machine. The adhesive tape rotating disc winding machine comprises a substrate. A support, a compression roller and a receiving disc are sequentially arranged in the length direction of the substrate. An adhesive tape rotating disc is arranged on the support and comprises an outer side adhesive tape rotating disc body and an inner side adhesive tape rotating disc body. The width of adhesive tape of the outer side adhesive tape rotating disc body is larger than the width of adhesive tape of the inner side adhesive tape rotating disc body. The adhesive tape of the adhesive tape rotating disc penetrates through the compression roller and stretches to the receiving disc, the combined ends of the adhesive tape are connected with the receiving disc, and a cutting device is arranged between the receiving disc and the compression roller. By the adoption of the technical scheme, the adhesive tape rotating disc winding machine of the transformer adhesive tape packaging machine can conveniently and quickly wind adhesive tape, and the adhesive tape packaging effect is good.

Owner:CHONGQING JUKANG BUILDING MATERIAL

Rubber coating and feeding mechanism of winding machine

ActiveCN111710525ACut tape works wellHigh tape cutting efficiencyCoils manufactureWinding machineAdhesive belt

The invention relates to a rubber coating and feeding mechanism of a winding machine. The mechanism comprises an up-and-down moving motor, adhesive tape disc rack, an adhesive tape disc and an adhesive tape detection wheel, a first attenuation connecting rod, a second attenuation connecting rod, an attenuation rod, an attenuation shaft, a reset spring, a limiting screw, a tape pulling transverse plate, an adhesive tape shaft, an insulating tape clamping air cylinder, a retaining wall adhesive tape clamping air cylinder, an insulating tape lower clamp, a retaining wall adhesive tape lower clamp, a front adhesive tape clamping plate, a rear adhesive tape clamping plate, a bag pulling lower transverse plate, a bag pulling upper transverse plate and a transverse plate moving guide rail assembly. Due to the overall structural design, various different adhesive tapes can be automatically wrapped on a workpiece on the same equipment, a series of operations such as adhesive tape conveying, adhesive tape detecting, adhesive tape clamping, adhesive tape positioning to the surface of a to-be-coated workpiece, coating of various different adhesive tapes on the workpiece, attenuation adjustmenton the adhesive tapes and cutting off of the various different adhesive tapes after coating operation are also realized. The rubber coating and feeding mechanism has the advantages of being high in rubber coating efficiency, good in rubber coating effect and high in rubber coating precision.

Owner:苏州创易技研股份有限公司

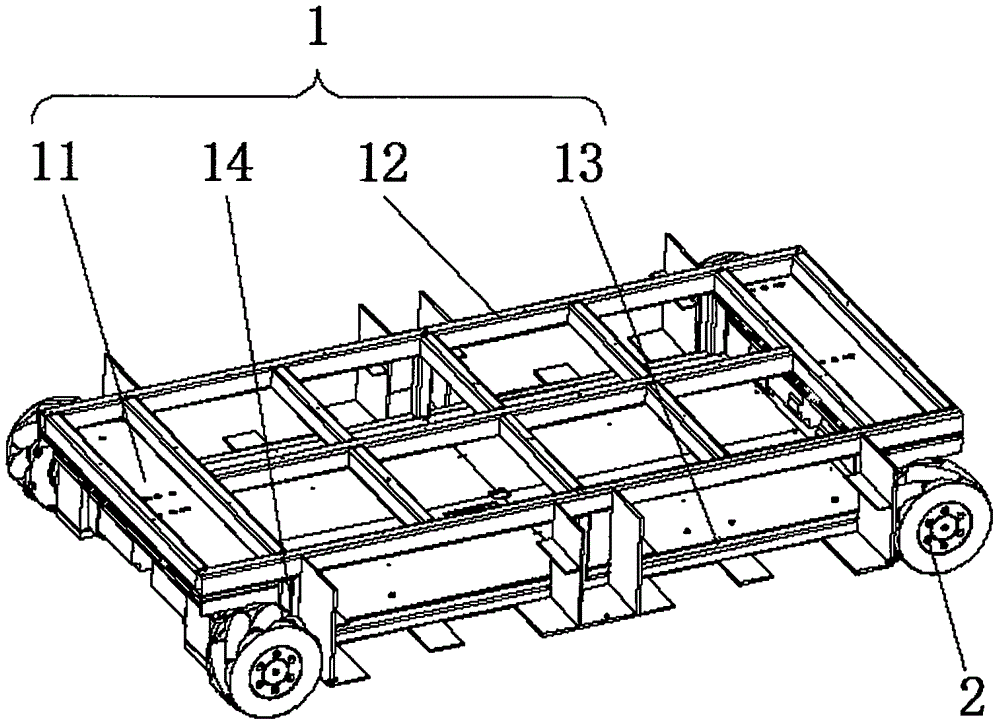

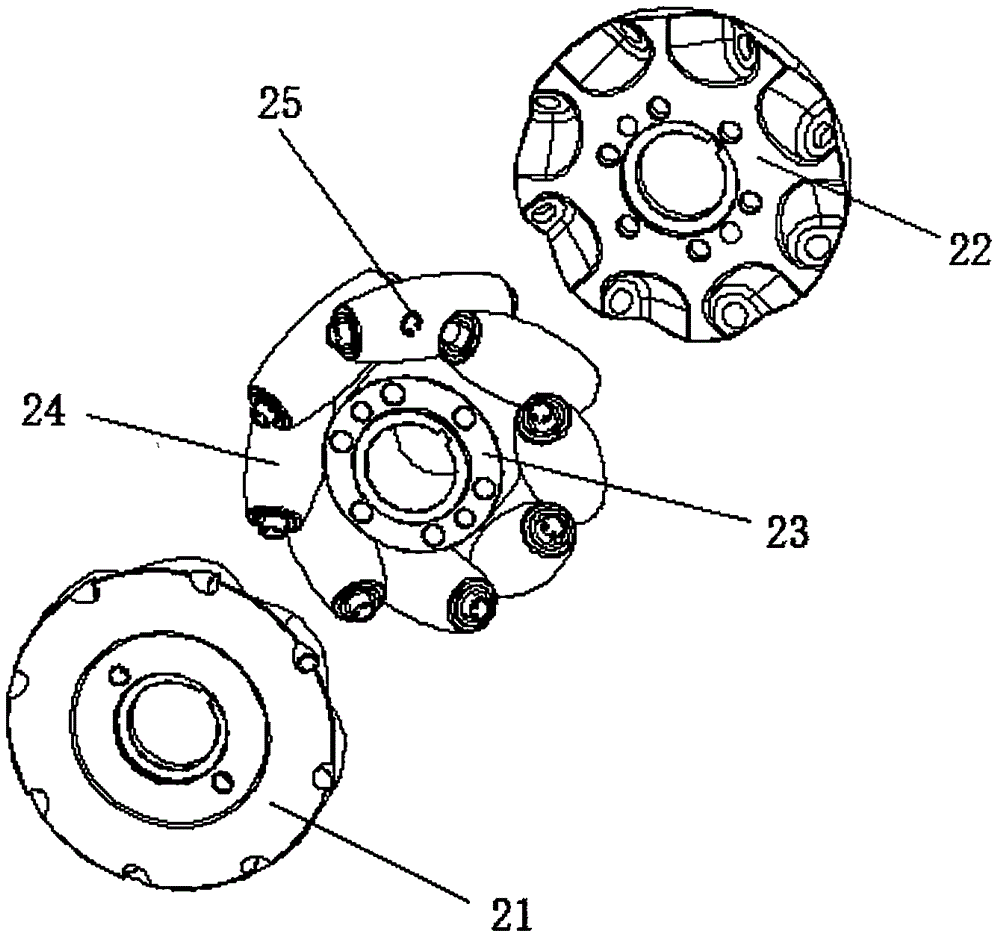

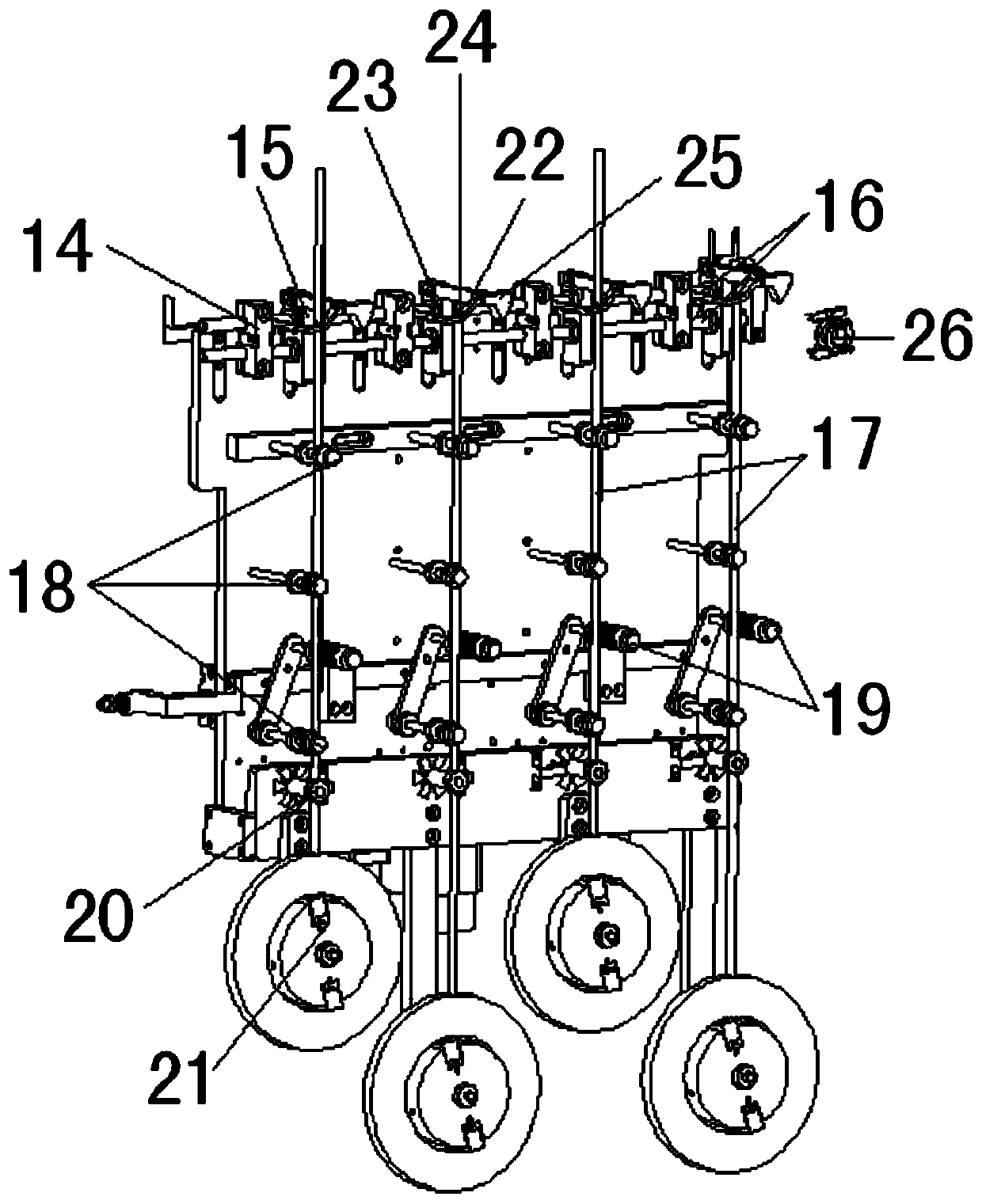

Intelligent omni-directional carrying robot

InactiveCN106828662AGuaranteed positioning and installationImprove assembly accuracyWheelsVehiclesAgricultural engineeringOmni directional

The invention relates to an intelligent omnidirectional handling robot, which has a frame and omnidirectional wheels; the omnidirectional wheels are installed on the frame; the frame includes a reference bottom plate and an upper frame; There are positioning connection holes; the upper frame is fixedly connected to the reference base plate. The invention has high manufacturing precision, efficient and fast assembly, high structural strength, long service life and convenient later maintenance.

Owner:常州模威科技有限公司

Retaining wall encapsulation, adhesive tape reverse folding, winding and pipe sleeving all-in-one machine

InactiveCN111755239AHigh winding precisionImprove the winding effectCoils manufactureWinding machineWire rod

The invention discloses a retaining wall encapsulation, adhesive tape reverse folding, winding and pipe sleeving all-in-one machine, which comprises a multi-sleeve feeding mechanism, a multi-wire-diameter wire feeding mechanism, a sleeve storing and penetrating mechanism, a wire arranging mechanism, a winding mechanism, a retaining wall mechanism, an encapsulation mechanism, a reverse folding mechanism, a wire end trimming and shaping mechanism and a finished product discharging barrel. According to the invention, a plurality of different processes such as conveying and feeding of a pluralityof different sleeves, conveying and feeding of a plurality of wires with different specifications, threading of the wires into the sleeves, retaining wall adhesive tape encapsulation, winding, adhesive tape encapsulation, reverse folding adhesive tape gluing, trimming, shaping of wire ends and discharging of finished products can be automatically carried out on a framework coil on one set of equipment; there is no need of purchasing multiple sets of equipment or use a large area to place the equipment, the all-in-one machine has the advantages of being high in working efficiency, good in winding effect, good in encapsulation effect and low in production cost, and the problems that the working efficiency is low, the labor intensity of workers is high and the labor cost of enterprises is high due to the fact that the framework coil is machined in a manual operation mode traditionally are solved.

Owner:湖北省磁特科技有限公司 +1

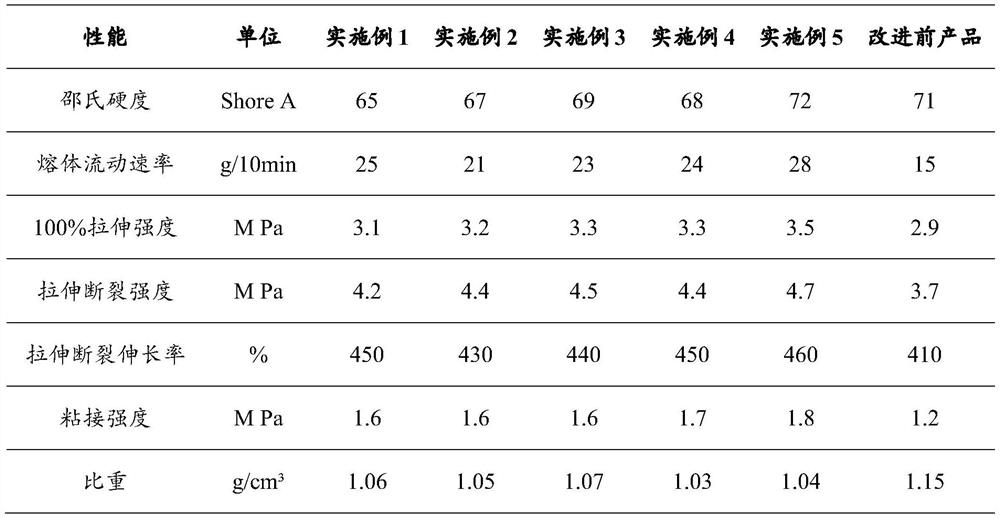

TPE nylon rubber-coated particle material with high fluidity and high binding power and preparation method thereof

The invention discloses a TPE nylon rubber-coated particle material with high fluidity and high binding power and a preparation method thereof. The TPE nylon rubber-coated particle material comprises the following components by weight: 10-20 parts of a styrene elastomer, 20-40 parts of white oil, 5-10 parts of a maleic anhydride grafted polystyrene elastomer, 5-10 parts of maleic anhydride grafted polyethylene, 10-20 parts of maleic anhydride grafted POE, 10-20 parts of polypropylene and 10-20 parts of calcium carbonate. The preparation method comprises the steps of raw material preparation, raw material blending, secondary rubber mixing, plastication extrusion, cooling granulation and the like, and by introducing the new material maleic anhydride grafted POE, the adhesion and compatibility of a polar material and a non-polar material are improved, and the fluidity of the system and the adhesion of the material and nylon are improved. The nylon rubber-coated particle material can improve the surface coating degree and adhesion strength of a product, and is suitable for products with complex structures and peculiar shapes.

Owner:南京文斯特新材料有限公司

Adhesive tape wrapping mechanism

PendingCN111370228AFlexible implementation of lagging operationsHigh consumption rateCoils manufactureAdhesive beltEngineering

The invention provides an adhesive tape wrapping mechanism. The adhesive tape wrapping mechanism comprises an adhesive tape wrapping machine moving platform, a lifting sliding assembly, a front-back push plate, a longitudinally and transversely moving base, a left-right sliding assembly, a lifting motor, a left-right driving motor, a winding shaft, a front-back moving motor, a front-back sliding bearing assembly, an air cylinder for clamping adhesive tapes and the like. The adhesive tape wrapping machine moving platform comprises a plurality of fixed driving clamp seats, a plurality of fixed driven clamp seats, driving clamp seat transmission rods, adhesive tape passing shafts, attenuation shafts, adhesive tape detection wheels, adhesive tape discs, driven adhesive tape clamps, driving adhesive tape clamps, adhesive tape cutting blades, polyurethane blocks and a framework. By means of overall structural design, an adhesive tape does not need to be broken when winding and right-angle bending are carried out on the framework, a perfect right angle can be bent through one-time adhesive tape wrapping, the defect that an adhesive tape wrapping machine of a traditional structure needs toconduct wrapping twice to bend a right angle is overcome, and the adhesive tape wrapping mechanism has the advantages of high adhesive tape wrapping efficiency, good adhesive tape wrapping effect andlow adhesive tape wrapping cost.

Owner:苏州创易技研股份有限公司

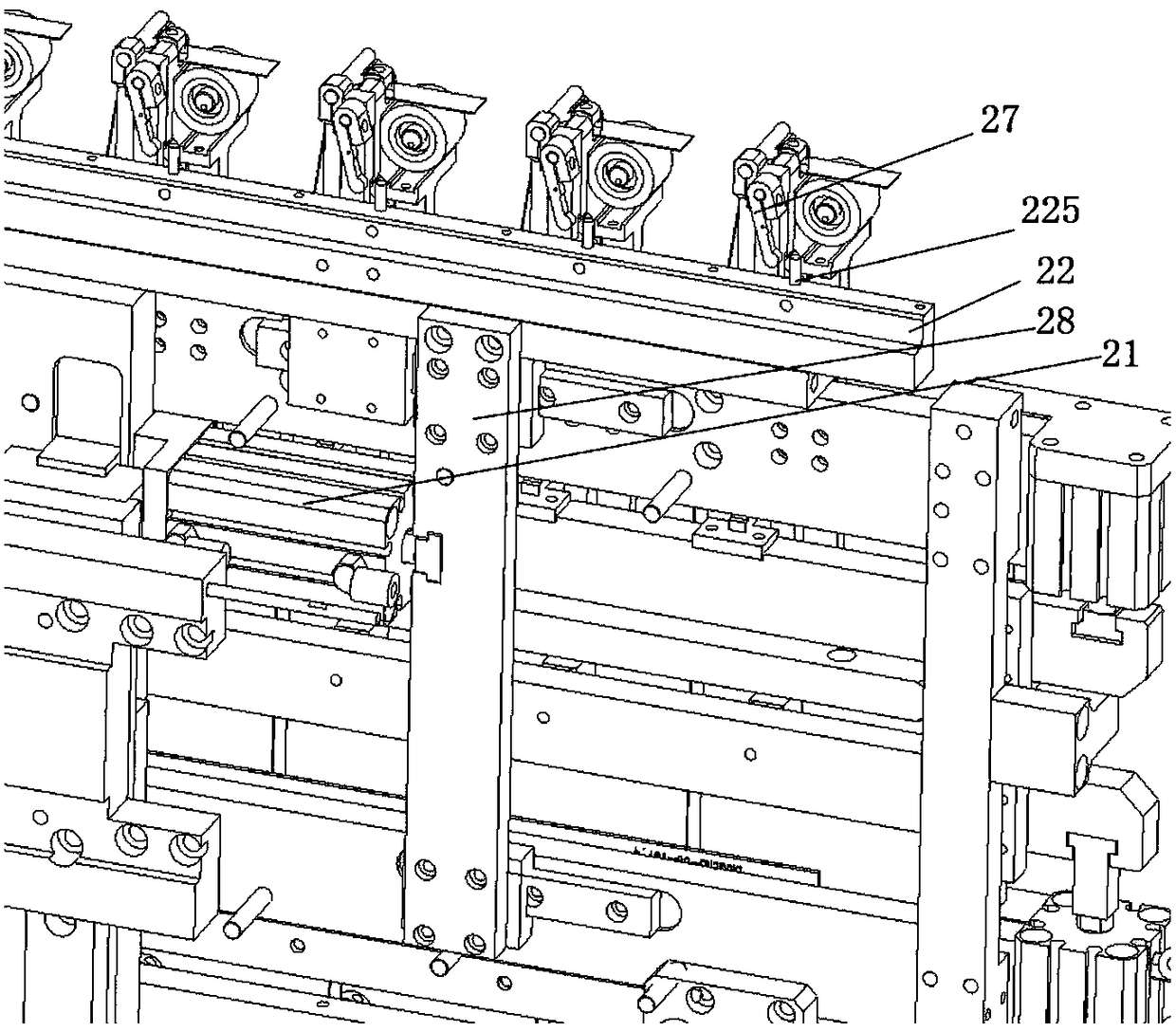

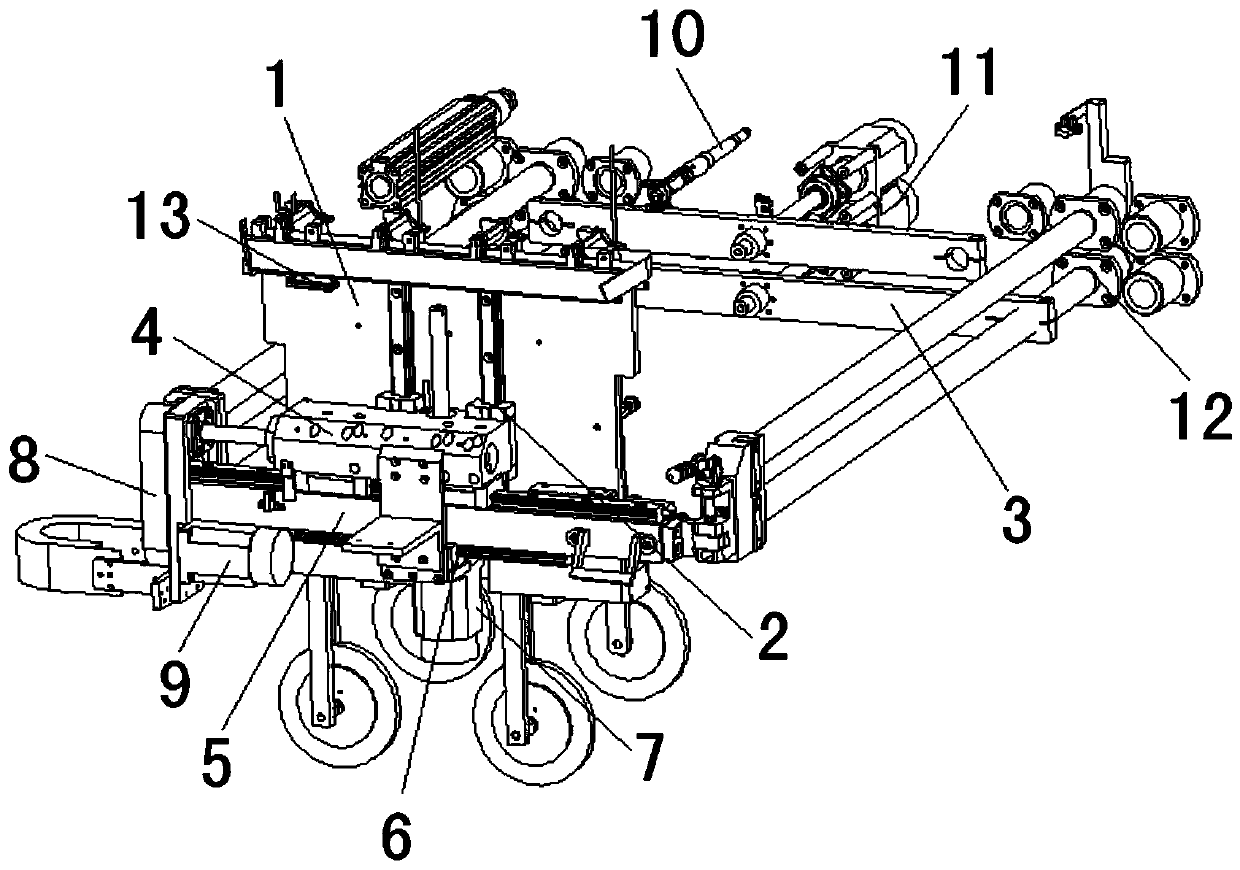

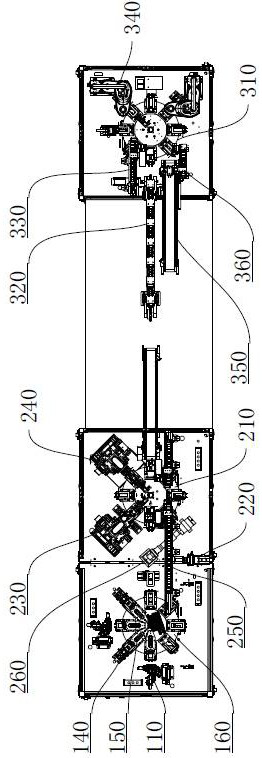

Transformer assembly line

ActiveCN112802676AEasy to operateImprove lagging effectTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureWire rodMolding machine

The invention discloses a transformer assembly line, which comprises: a rubber coating machine, which comprises a rubber coating workpiece conveying device and a rubber coating unit, wherein the rubber coating unit is located on the side of the rubber coating workpiece conveying device; a wire forming machine, which comprises a formed workpiece conveying device, a wire bending mechanism, a wire forming mechanism, a wire shearing mechanism, a workpiece transferring mechanism and a tin coating mechanism; and a tin soldering machine, which comprises a tin soldering workpiece conveying device, a tin soldering feeding conveying belt, a tin soldering feeding mechanism, a tin soldering mechanism, a tin soldering blanking conveying belt and a tin soldering blanking mechanism. The whole production efficiency is improved, the product quality problem caused by worker errors, unskilled operation and the like is reduced, and the production benefit is greatly improved.

Owner:广东昭信智能装备有限公司

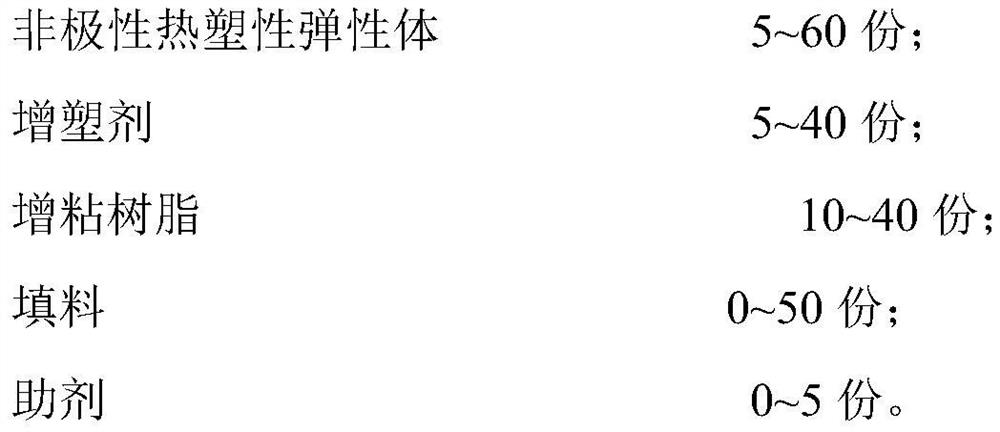

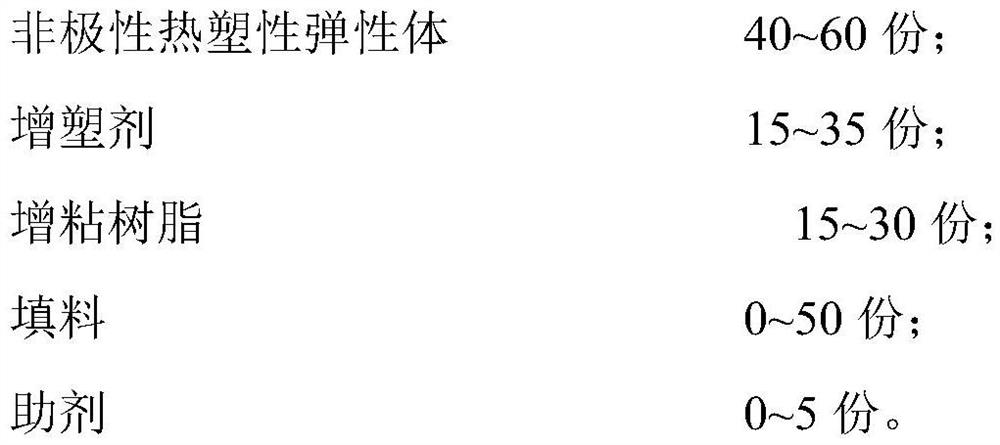

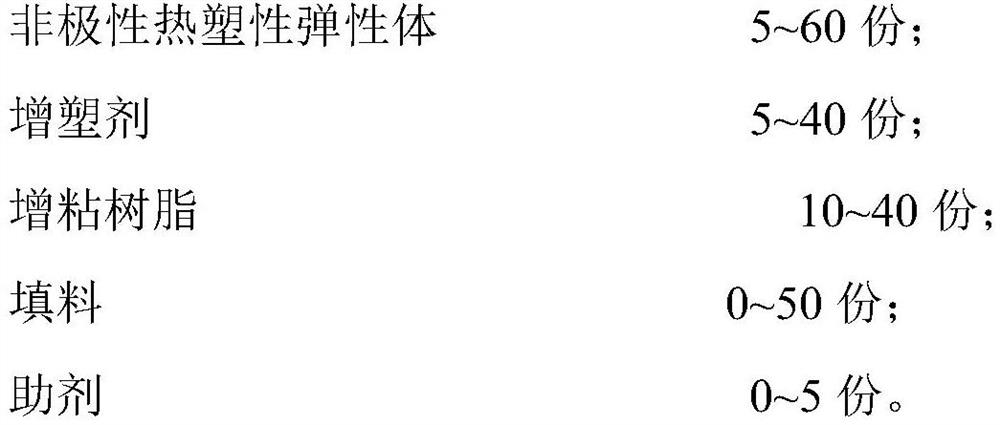

Thermoplastic elastomer composition for LCP coatingas well as preparation method and application thereof

The invention discloses a thermoplastic elastomer composition for LCP coating as well as a preparation method and application thereof. According to the invention, a non-polar thermoplastic elastomer is used as a base material, and the thermoplastic elastomer composition is prepared from the base material, a plasticizer, tackifying resin and other components according to a certain ratio. The compatibility between two phases is improved by utilizing the mechanism that ester groups of the tackifying resin and amino groups in a molecular structure of the LCP are easily subjected to condensation reaction, so that the bonding force between the two phases is improved, the bonding effect between a TPE alloy material and the LCP is improved, the processing temperature is high, the TPE alloy material is used for coating the LCP, the bonding property between the TPE alloy material and the LCP can be improved, and the rubber coating effect is good. The thermoplastic elastomer composition disclosed by the invention can be widely applied to LCP coating.

Owner:KINGFA SCI & TECH CO LTD

Encapsulation device for high-frequency transformer and encapsulation method thereof

PendingCN110246673AImprove stabilityNot easy to fall offEncapsulation/impregnationTransformerEngineering

The invention discloses an encapsulation device for a high-frequency transformer. The device comprises a bottom frame and a fixing ring; a top frame is welded to one end of the top of the bottom frame; a mounting frame is mounted on the upper portion of the bottom frame; the bottom of the mounting frame is slidably connected with the two sides of the bottom frame; a second rotating shaft is rotatably mounted at the top end in the mounting frame; and a first rotating shaft and a loading shaft are rotatably mounted at the upper end and the lower end of the side, away from the mounting frame, of the mounting frame correspondingly. In the winding process, the wound adhesive tape is extruded through multiple pressing rings, so the pressing force for wrapping the adhesive tape is increased, the adhesive tape is wrapped more firmly, and loosening is not likely to happen. Along with the continuous increase of the wrapping amount of the adhesive tape, a hydraulic column continuously contracts to drive a support to be far away from the transformer, so that the pressure rings can pressurize the adhesive tape for the encapsulation, and the normal proceeding of the encapsulation is not influenced. The encapsulation effect is better, and the working efficiency is improved.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

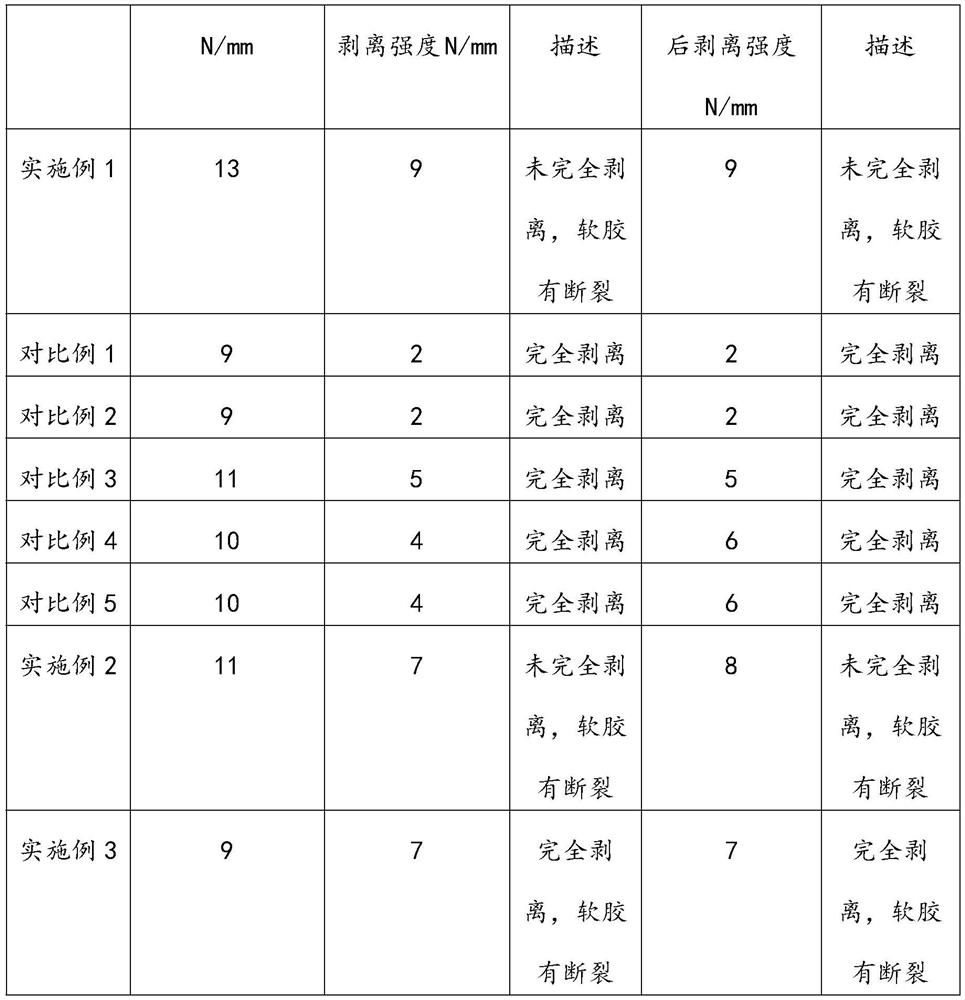

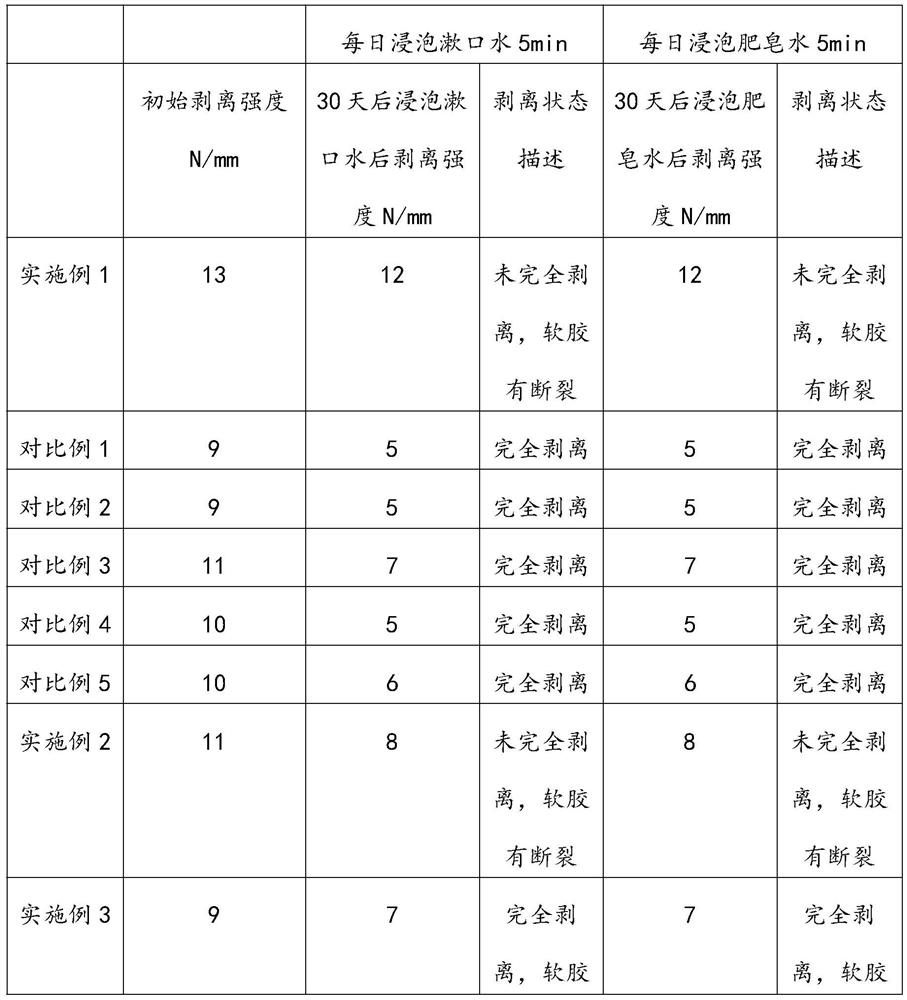

A preparation method for a plastic-coated handle of an electronic product for personal care

The invention relates to a method for preparing a rubberized handle of an electronic product for personal care, wherein SEBS can reduce the hardness of polyester or polyether TPU; polyester or polyether TPU is grafted with maleic anhydride SEBS / Maleic anhydride grafted ABS will undergo a hydrogen abstraction reaction during extrusion and granulation to form TPU grafted SEBS / ABS; mineral oil will not produce small molecular substances at high temperatures, thereby improving the strength and bonding of the encapsulation material degree; the urethane bond on polyester or polyether TPU reacts with thermal dissociation products to form isocyanate, soft and hard modified TPU react with each other, maleic anhydride and isocyanate in soft and hard modified TPU A graft copolymer is formed on the interface, so that a force other than hydrogen bond and van der Waals force is formed between the soft and hard modified TPU, which is conducive to maintaining the combination of the obtained material in a weak acid / weak alkaline environment Strong, not easy to peel off.

Owner:MIRACLL CHEM

A kind of ro film automatic encapsulation and cutting mechanism

ActiveCN105435642BIncrease productivityImprove lagging effectMembranesSemi-permeable membranesReverse osmosisEngineering

The invention applies to the technical field of RO (reverse osmosis) membrane production and provides an automatic tape coating and cutting-off mechanism for an RO membrane. The automatic tape coating and cutting-off mechanism comprises a tape winding bracket, an adhesive tape sliding shaft for guiding an adhesive tape, adhesive tape sleeve joint assemblies for sleeve joint of a wound adhesive tape material, an adhesive tape adsorption bottom plate, a tape cutting blade and a sliding cylinder, wherein the adhesive tape sliding shaft, the adhesive tape sleeve joint assemblies, the adhesive tape adsorption bottom plate and the sliding cylinder are all mounted on the tape winding bracket; the adhesive tape sleeve joint assemblies are located below the adhesive tape sliding shaft; the adhesive tape adsorption bottom plate is horizontally arranged on one side of the adhesive tape sliding shaft; the sliding cylinder is fixed below the adhesive tape adsorption bottom plate; the tape cutting blade is fixedly connected onto a sliding base of the sliding cylinder and extends out of the upper surface of the adhesive tape adsorption bottom plate. The wound adhesive tape material in sleeve joint on the adhesive tape sleeve joint assemblies is automatically wound and pulled and coats the rotating RO membrane, and the tape cutting blade cuts off the tape after the tape coating is finished. The automatic tape coating and cutting-off mechanism has the advantages of low production cost, high production efficiency and excellent tape coating effect.

Owner:SHENZHEN SECOND INTELLIGENT EQUIP CO LTD

Field maintenance method for coating layer of material taking machine head part roller

The invention provides a field maintenance method for a coating layer of a material taking machine head part roller. The field maintenance method comprises the following steps that whether the returndistance of the head part roller meets the requirement for sectional coating or not is judged; the position and the operation space of a conveying belt are pre-adjusted; the conveying belt is slowly pulled out of a carrier roller frame along the vertical direction of the belt conveyor, and the head part roller is exposed to be close to one half of a barrel body; cold vulcanization packaging is carried out on the exposed part of the head part roller, and static curing is carried out after the head part roller is completed; the residual part of the head part roller is subjected to cold vulcanization and coating, the joint of the coated rubber layer is treated, and static curing is completed. The field maintenance method for the coating layer of the material taking machine head part roller, through the pre-adjustment of the conveying belt, the segmented coating of the head part roller and the joint processing of the coating layer, so that the segmented coating of the rubber layer of the head part roller can be realized, and the field maintenance method has the characteristics of no damage to the conveying belt, convenience in operation and good rubber coating effect.

Owner:天津港远航国际矿石码头有限公司

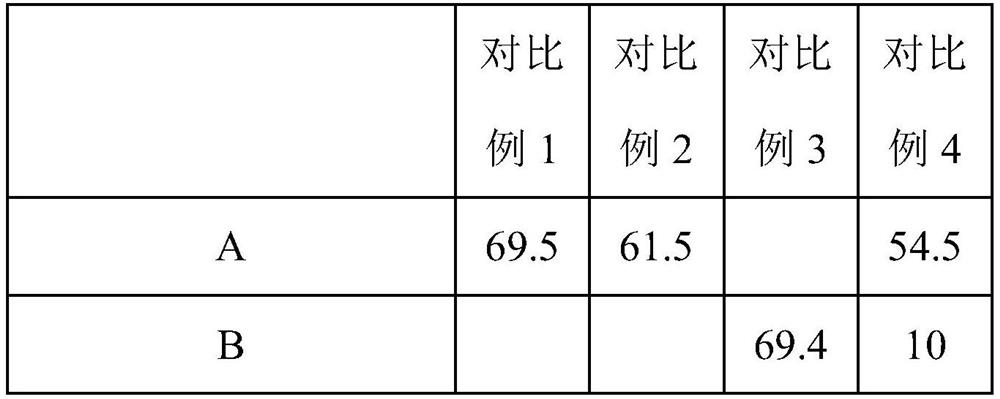

A kind of TPE encapsulation material and preparation method thereof

The invention relates to a TPE encapsulation material and a preparation method thereof, belonging to the technical field of TPE encapsulation. The TPE encapsulation material of the present invention includes the following raw material components in weight percentage: SEBS 12-30%, TPU 35-60%, plasticizer 15-30%, filler 0-10%, release agent 0.5-2%, 0.8-1.6% of other additives, and the melt index of the TPU is 70-90g / 10min. The TPE encapsulation material of the present invention has high viscosity, good encapsulation property and is not easy to unglue.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

Auxiliary rubber coating assembly

The invention discloses an auxiliary rubber coating assembly which is characterized in that the auxiliary rubber coating assembly is arranged in a mould core of a mould; the auxiliary rubber coating assembly comprises a thread body, a spring and a steel ball; a thread structure is arranged on the external surface of the thread body; a first blind hole is formed at one end of the thread body; the spring and the steel ball positioned at one end of the spring are mounted in the first blind hole; and a part of the external surface of the steel ball protrudes out of the first blind hole. When the mould core is coated with a rubber coating piece, the rubber coating piece pushes against the steel ball of the auxiliary rubber coating assembly, the spring is compressed, the steel ball retracts back, and a counter-acting force of the spring acts on the rubber coating piece simultaneously to allow the steel ball and the rubber coating piece to be clamped with each other. In this way, the auxiliary rubber coating assembly can remove dimensional variation between the varisized rubber coating pieces and the mould cores, thereby achieving a better rubber coating effect. In addition, a contact area between the steel ball and the rubber coating piece is less, thereby facilitating taking products.

Owner:HAIMEN RUNSHENG TEXTILE

TPE rubber coating material and preparation method thereof

The invention relates to a TPE rubber coating material and a preparation method thereof, and belongs to the technical field of TPE rubber coating. The TPE rubber coating material is prepared from thefollowing raw material components in percentage by weight: 12-30% of SEBS, 35-60% of TPU, 15-30% of a plasticizer, 0-10% of filler, 0.5-2% of a release agent and 0.8-1.6% of other auxiliary agents, wherein the melt index of TPU is 70-90g / 10min. The TPE rubber coating material is high in viscosity, good in coating performance and not prone to glue failure.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

A kind of high-performance thermoplastic elastomer and its processing method

The invention provides a high-performance thermoplastic elastomer and a processing method thereof. The high-performance thermoplastic elastomer comprises the following components in parts by weight: 20-100 parts of polyether elastomer TPEE, 0-70 parts of styrene elastomer, 0-30 parts of maleic anhydride-grafted SEBS, 0-50 parts of rubber filling oil, 0-40 parts of mineral powder and 0-5 parts of a stabilizer. The thermoplastic elastomer with high strength and stable performance can be produced by virtue of different raw materials and proportions; a processing process temperature (190-260 DEG C) of the high-performance thermoplastic elastomer is wider in range in comparison with that of the conventional TPU (thermoplastic polyurethane) and an alloy product thereof. The adopted extruder screw head can be used for lowering the melt temperature, lowering the material decomposition and promoting the materials to uniformly mix, so that obtained high-performance thermoplastic elastomer is high in strength, stable in performance, excellent in weather resistance and yellowing resistance, and excellent in rubber coating effect.

Owner:安特普工程塑料(苏州)有限公司

A kind of disc-type aluminum-nickel lug encapsulation method

ActiveCN111554865BImprove lagging effectImprove sealingElectrode manufacturing processesSecondary cellsNickel electrodeMechanical engineering

The invention discloses a disc-type aluminum-to-nickel lug coating method, which relates to the technical field of lithium battery lug production. The invention comprises the following steps: Step 1: Clean the aluminum-to-nickel lug to be coated with a cleaning roller, and clean up the sundries attached to the surface of the weld between the aluminum strip and the nickel strip; Step 2: Use a grinding tool to clean the aluminum strip and the nickel strip. Grinding the surface of the welded part of the nickel strip to make it rough; Step 3: Clean the polished aluminum-to-nickel lug through the cleaning roller again to remove the residue after grinding on the surface of the welded part of the aluminum strip and the nickel strip. In the present invention, the aluminum-to-nickel lug is coated once, twice, and three times, and the two kinds of lugs are matched together, so that the encapsulation performance of the aluminum-to-nickel lug is better, and the lug is improved. Excellent airtightness, by roughening the surface of the material before heat sealing, the microscopic pits on the surface of the material greatly enhance the bonding force between the tape and the metal tape and between the tape and the tape, making the compatibility between layers Better resistance, not easy to fall off.

Owner:广东佐林新能源科技有限公司

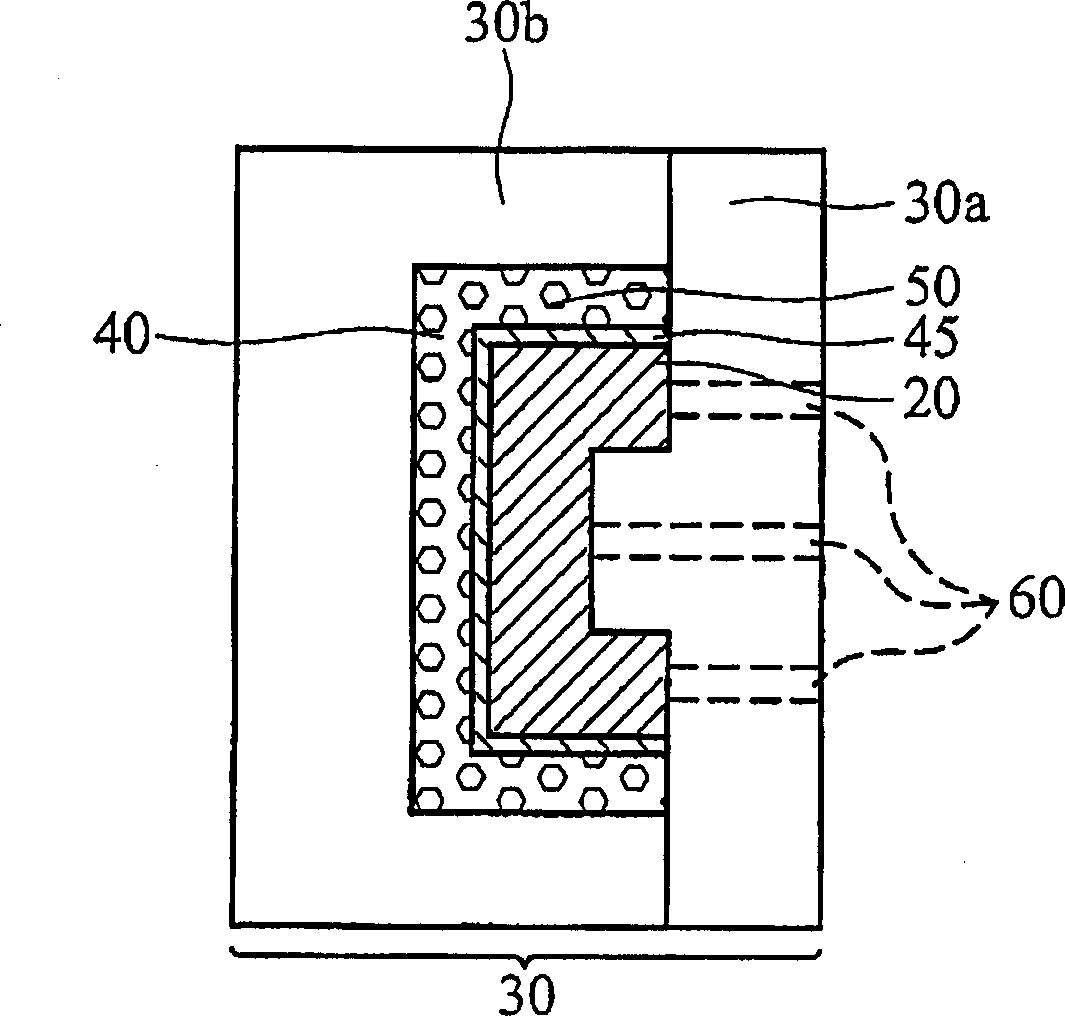

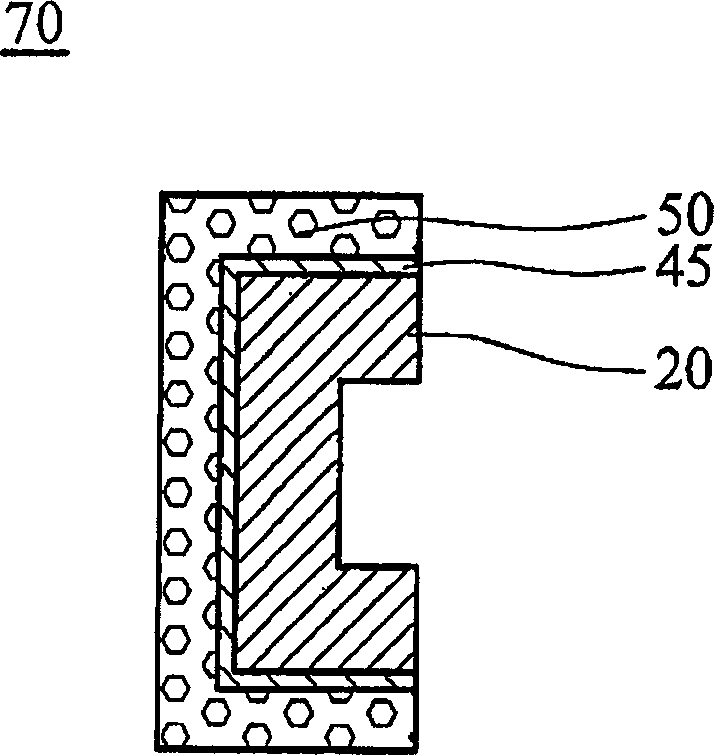

Full coated encapsulate formed article and its forming method

The present invention provides a kind of fully coated article and its forming process. The forming process includes the following steps: forming polymer biscuit in mold; setting the biscuit in room temperature for 15-30 hr to stabilize size; setting the biscuit inside coating mold with notches; injecting coating material of thermoplastic elastomer in hardness 70-90 A at the jetting speed of 12-28 cu cm / sec into the coating mold at 160-210 deg C to fill the notches with the coating material and to form surface coating on the biscuit; hardening the coating material; taking out the coated article and cooling to obtain the fully coated article.

Owner:HANNSPREE INC

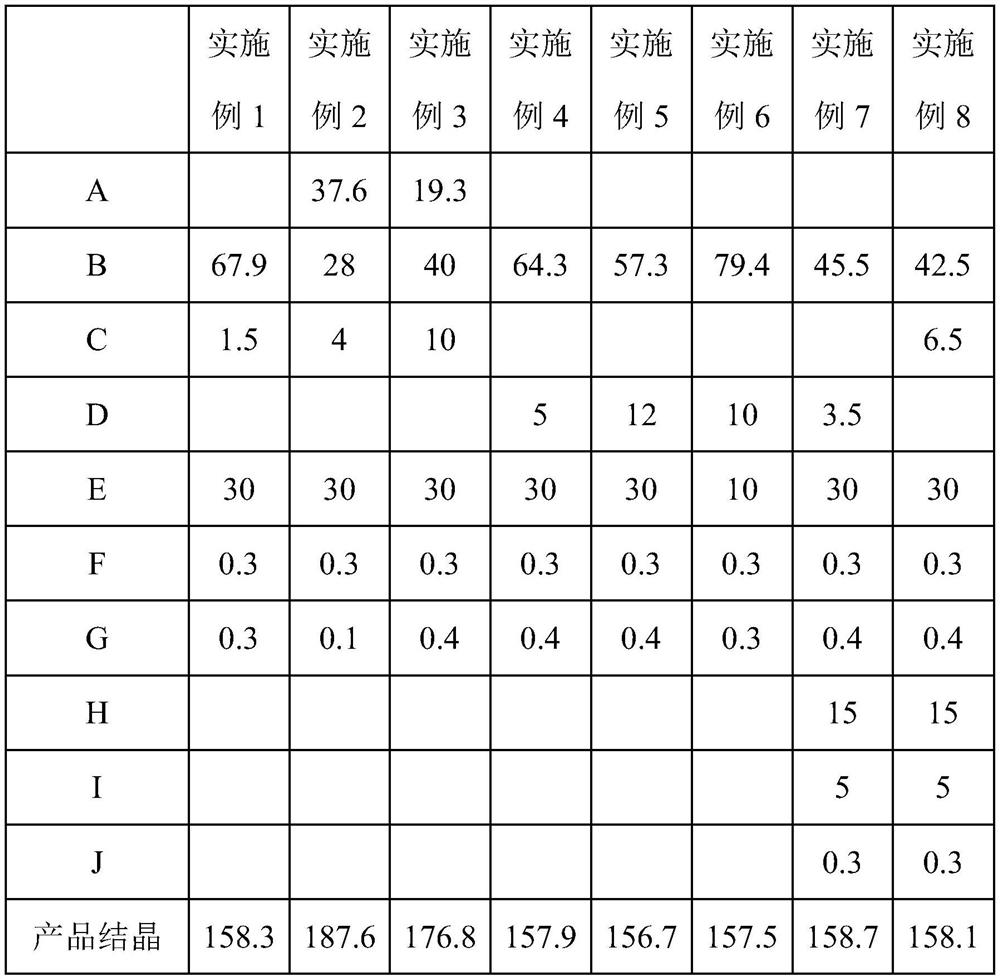

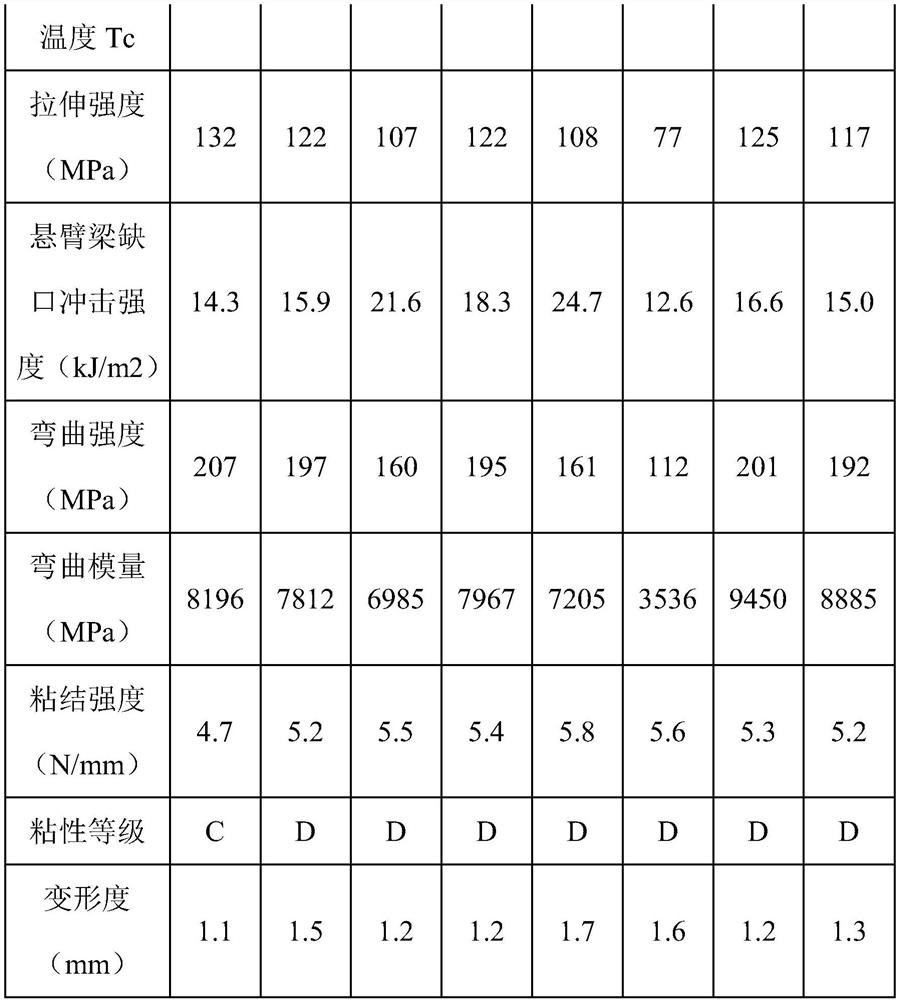

Polybutylene terephthalate composition for TPE encapsulation and preparation method thereof

ActiveCN112552658AImprove lagging effectImprove adhesionPolytetramethylene terephthalatePolymer chemistry

The invention provides a polybutylene terephthalate composition for TPE encapsulation. The polybutylene terephthalate composition is characterized by being prepared from the following raw materials inpercentage by weight: 35 to 94 wt% of PBT resin, 1 to 15 wt% of a toughening agent and 5 to 50 wt% of a filling agent; after the PBT resin passes through a twin-screw extruder, the range of the crystallization temperature Tc obtained at a cooling rate of 10 DEG C / min above the melting point of the PBT resin is 140 to 190 DEG C; the toughening agent is an active group copolymerization type or reaction grafting type toughening agent, and the content of active groups of the copolymerization type or grafting type toughening agent is more than 0.4% and less than 10%. The polybutylene terephthalatecomposition for TPE encapsulation is high in binding power, not prone to stripping and excellent in material impact performance, and has the advantages of being high in comprehensive performance, lowin warping performance and high in processability.

Owner:TIANJIN KINGFA NEW MATERIAL

A high-voltage electrified overhead bare wire lifting crane and its rubber-covered spraying robot

ActiveCN109704220BEasy to operateThere is no potential safety hazard of electromagnetic interferenceLiquid surface applicatorsWinding mechanismsElectric power systemControl system

The invention belongs to the technical field of electric power systems, and relates to a high-voltage electrified aerial bare conducting wire lifting crane and a rubber coating spray painting robot ofthe high-voltage electrified aerial bare conducting wire lifting crane. A lifting device in the lifting crane comprises a wire speed adjusting device and wire winding devices, wherein the wire speedadjusting device is installed in the middle of the upper end of a machine frame, and the wire winding devices are installed on the two sides of the wire speed adjusting device. The wire speed adjusting device comprises a supporting frame, a worm and a worm wheel, wherein the supporting frame is installed on the machine frame, the worm is arranged on the supporting frame, and the worm wheel mesheswith the worm. A second hand wheel is fixedly installed on the outer side of the worm wheel, and a plurality of third hand wheels are evenly and fixedly installed on the upper side of the worm wheel.Each wire winding device comprises a wire winding roller, a guide rod and a first hand wheel. The wire winding rollers are fixedly arranged at the free ends of the worm, the guide rods are fixedly arranged above the wire winding rollers, and the first hand wheels are installed on the outer sides of the wire winding rollers. Sliding blocks are arranged on the guide rod in a penetrative mode, and traction wheels are fixedly installed on the sliding blocks. Pull ropes which are used for lifting the rubber coating robot are wound around the wire winding rollers, and the free ends of the pull ropespass through the traction wheels. The problem that in the prior art, the potential safety hazard exists in the mode that an automatic spray painting robot is conveyed by a control system is solved.

Owner:重庆洎皋电力科技有限责任公司

Laminated cell glue winding equipment

InactiveCN114229074ALess gluing stepsEasy to set upWrapping material feeding apparatusFinal product manufactureMechanical engineeringBattery cell

The invention discloses laminated battery cell glue winding equipment which comprises a machine table, a battery cell feeding displacement platform, a shaping station, a hot ironing station, a glue pasting and winding station, a glue preparation mechanism and a glue pressing mechanism are arranged on the machine table, a glue pasting and winding integrated mechanism is arranged on the glue pasting and winding station, a shaping mechanism is arranged on the shaping station, a hot ironing mechanism is arranged on the hot ironing station, and the glue pressing mechanism is arranged on the hot ironing station. The glue pasting and winding integrated mechanism is located between the glue preparation mechanism and the glue pressing mechanism, and the cell feeding displacement platform is controlled by a displacement driving mechanism to move. According to the method, the number of rubberizing steps is small, equipment arrangement is simpler, and rubber coating is more convenient.

Owner:GUANGDONG DONGBO AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com