A kind of TPE encapsulation material and preparation method thereof

A technology of encapsulation and raw materials, applied in the field of TPE encapsulation, can solve the problems of weak adhesion in local parts, inability to directly encapsulate ABS, easy to cause coke materials, etc., to achieve good spreading effect, improve encapsulation efficiency and encapsulation. Effect, good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

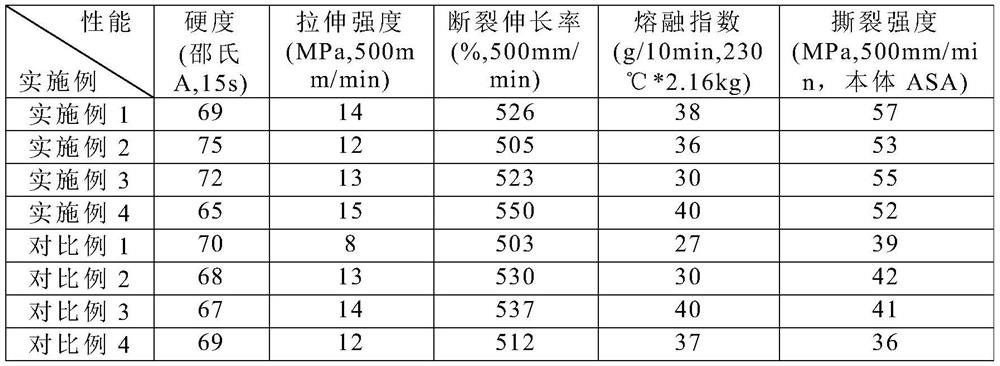

Examples

Embodiment 1

[0050] The preparation of the TPE encapsulating material in the present embodiment is as follows:

[0051] (1) Preparation of chloromethylated SEBS: the raw material SEBS is dissolved in dichloroethane to form a SEBS solution, the concentration of SEBS in the SEBS solution is 0.04g / mL, and the SEBS solution and chloromethyl methyl ether are added to the reflux device The catalyst was added with zinc chloride, and the reaction was carried out at 45 °C for 4 hours. The weight ratio of the raw material SEBS, chloromethyl methyl ether and the catalyst was 1:0.2:0.1. After the reaction was completed, methanol or ethanol was added as a precipitation agent for precipitation, and then the The drying of the precipitated product is chloromethylated SEBS;

[0052] (2) By weight percentage, prepare 22% chloromethylated SEBS, 52% TPU (melt index is 80g / 10min), 18% paraffin oil, 6% talc, 1% polytrifluoropropyl methylsiloxane Alkane (PTFPMS), 0.6% hindered phenolic antioxidant Irganox 1010,...

Embodiment 2

[0056] The preparation of the TPE encapsulating material in the present embodiment is as follows:

[0057] (1) Preparation of chloromethylated SEBS: the raw material SEBS is dissolved in dichloroethane to form a SEBS solution, the concentration of SEBS in the SEBS solution is 0.03 g / mL, and the SEBS solution and chloromethyl methyl ether are added to the reflux device In addition, the catalyst zinc chloride was added, and the reaction was carried out at 40 °C for 3 hours. The weight ratio of the raw material SEBS, chloromethyl methyl ether and the catalyst was 1:0.1:0.07. After the reaction was completed, the precipitant methanol was added for precipitation, and then the precipitated product was Drying is chloromethylated SEBS;

[0058] (2) By weight percentage, prepare 14% chloromethylated SEBS, 60% TPU (melt index is 80g / 10min), 15% paraffin oil, 9% talc, 1.2% polymethyl nonafluorohexylsiloxane Alkane (PMNFHS), 0.5% hindered phenolic antioxidant Irganox 1010, 0.3% benzophen...

Embodiment 3

[0062] The preparation of the TPE encapsulating material in the present embodiment is as follows:

[0063] (1) Preparation of chloromethylated SEBS: the raw material SEBS is dissolved in dichloroethane to form a SEBS solution, the concentration of SEBS in the SEBS solution is 0.04g / mL, and the SEBS solution and chloromethyl methyl ether are added to the reflux device The catalyst was added with zinc chloride, and the reaction was carried out at 45 °C for 4 hours. The weight ratio of the raw material SEBS, chloromethyl methyl ether and the catalyst was 1:0.2:0.1. After the reaction was completed, methanol or ethanol was added as a precipitation agent for precipitation, and then the The drying of the precipitated product is chloromethylated SEBS;

[0064] (2) By weight percentage, prepare 20% chloromethylated SEBS, 50% TPU (melt index is 70g / 10min), 21% paraffin oil, 7% talc, 0.9% polytrifluoropropyl methylsiloxane Alkane (PTFPMS), 0.5% hindered phenolic antioxidant irganox 107...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com