High-voltage electrified aerial bare conducting wire lifting crane and rubber coating spray painting robot thereof

A technology of spraying robots and high-voltage electrification, which is applied to overhead lines/cable equipment, coatings, clockwork mechanisms, etc., can solve problems such as potential safety hazards, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described in detail below.

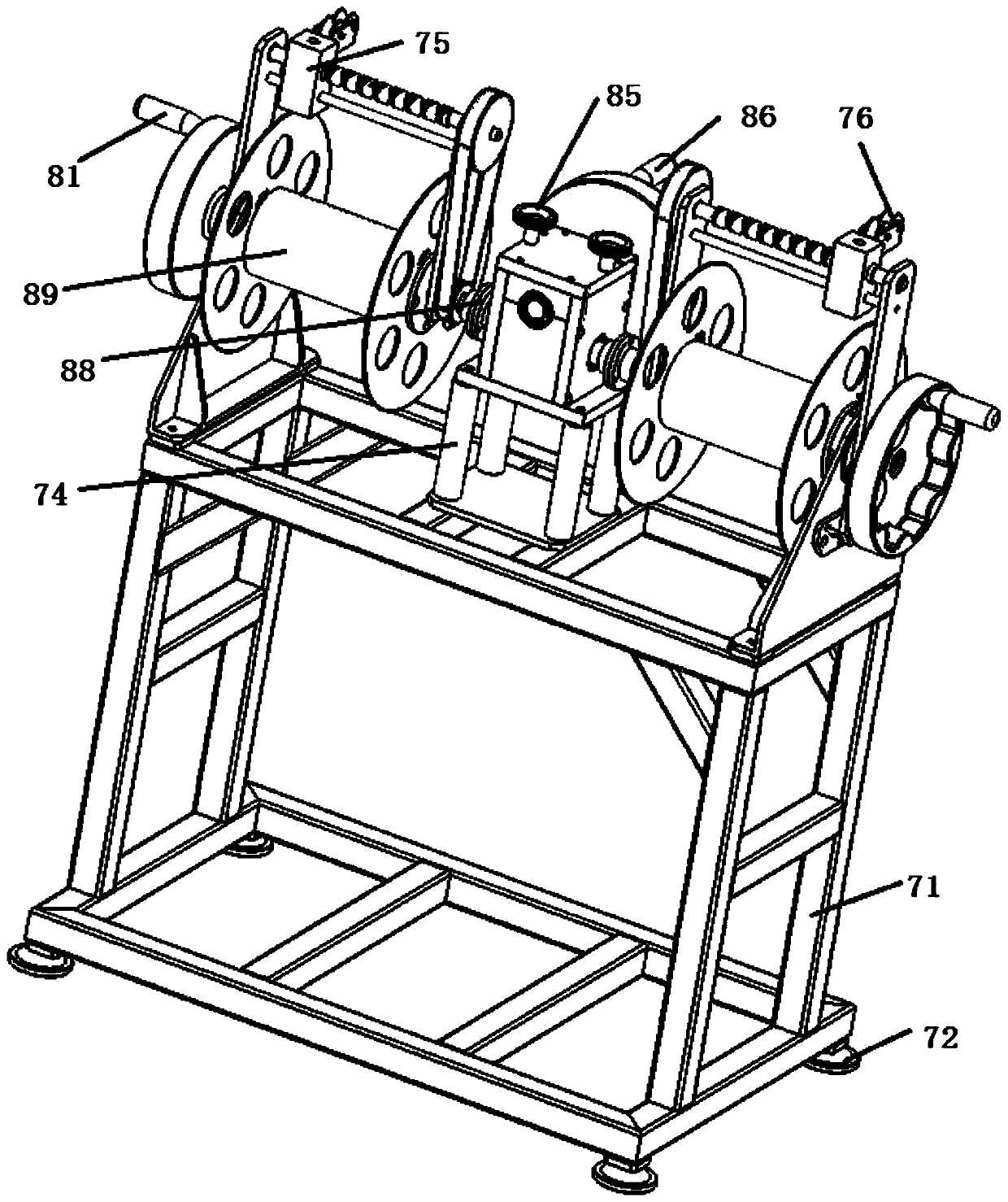

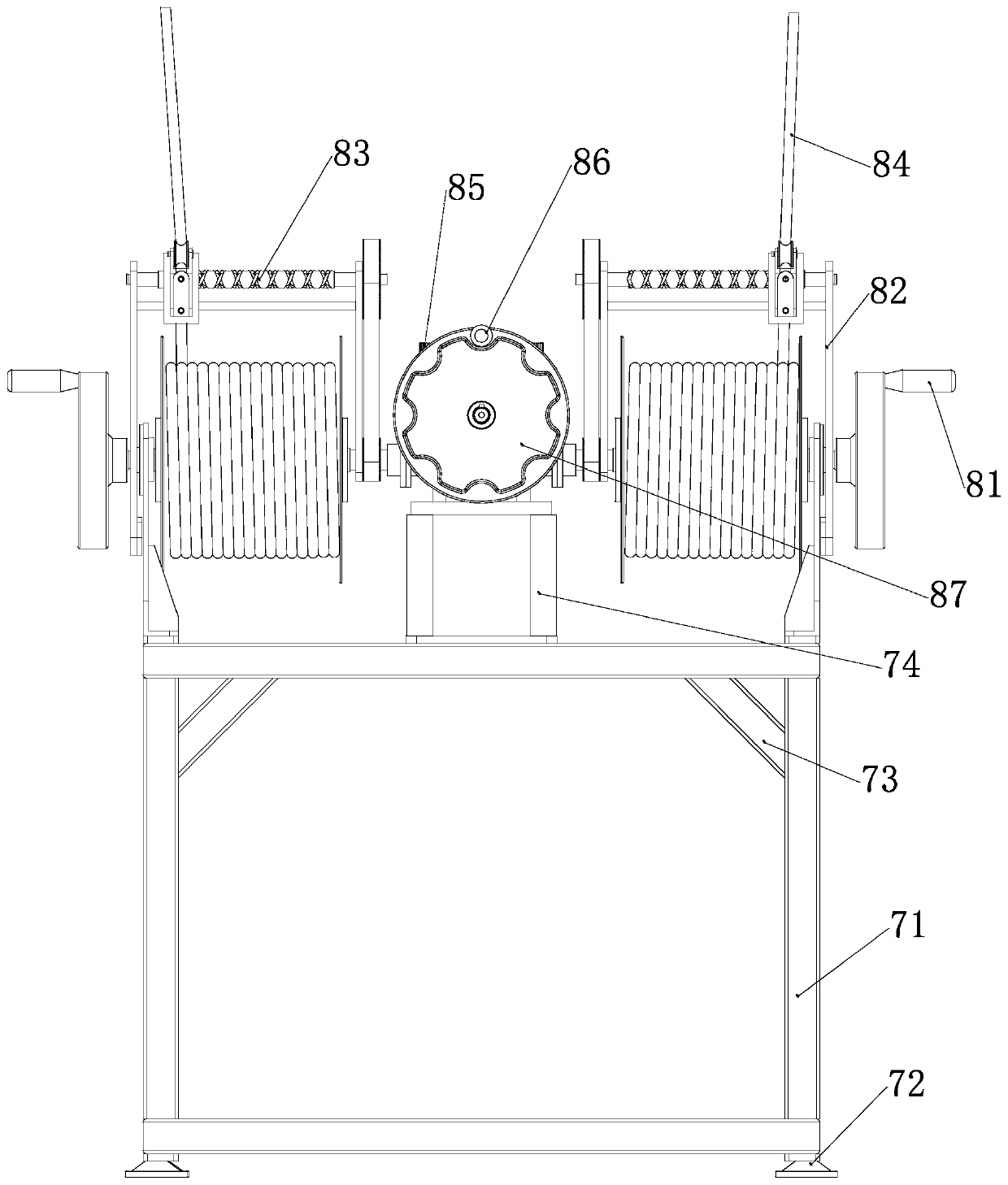

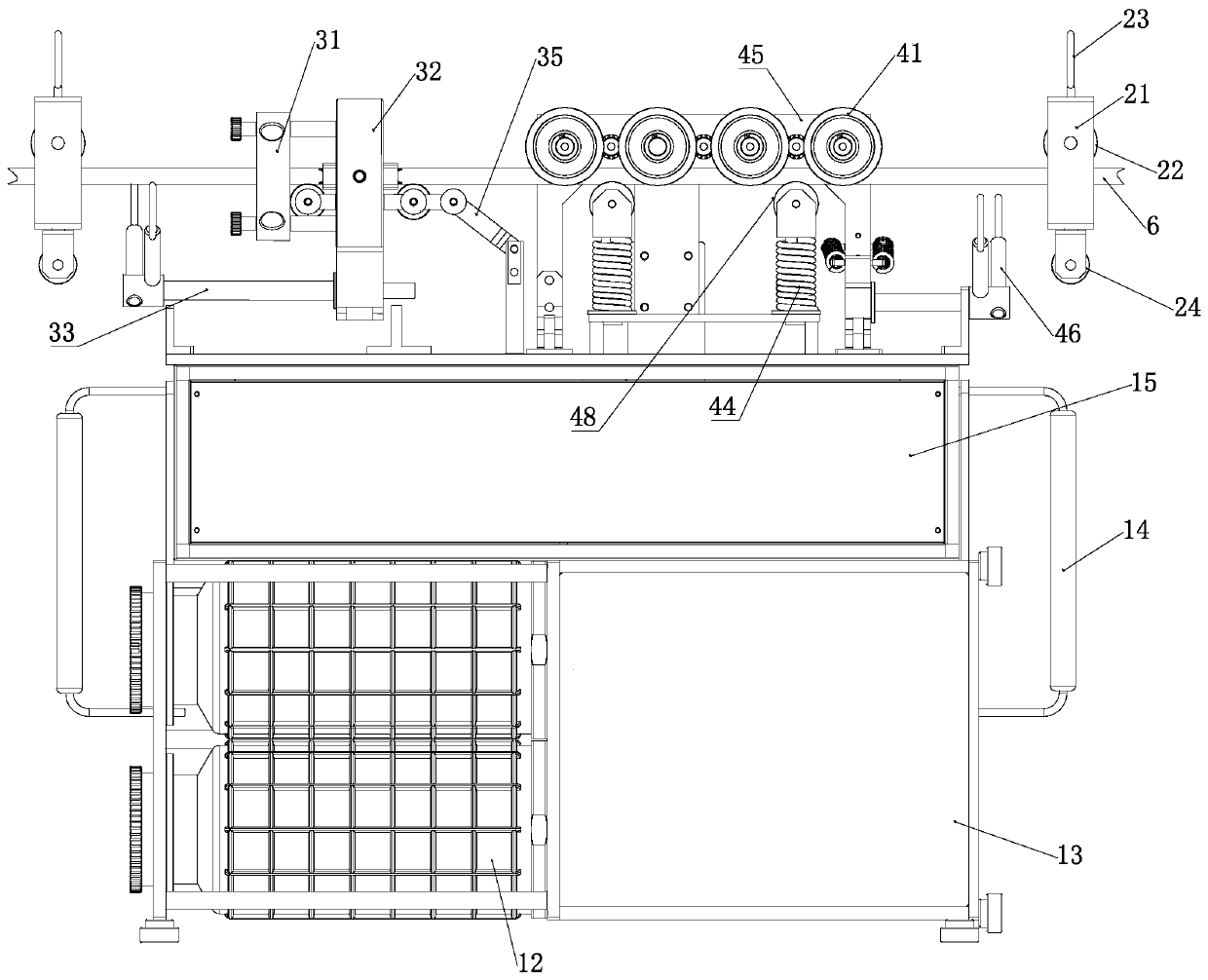

[0035] The reference signs in the drawings of the description include:

[0036] Cabinet 11, insulating paint bucket 12, sliding door 13, handle 14, motor box 15, locking block 21, third locking wheel 22, suspension ring 23, pulley 24, injection molding pressure ring 31, clamping arm 32, connecting rod 33. The first compression spring 34, the rotating arm 35, the first roller 36, the clamping block 37, the fixed rod 38, the pressure rod 39, the second locking wheel 41, the driven wheel 42, the conveyor belt 43, the second compression spring 44, Position plate 45, second rocker 46, gear 47, second roller 48, cleaning brush 5, bare wire 6, frame 71, supporting angle 72, reinforcing rib 73, support frame 74, slider 75, traction wheel 76 , the first handwheel 81, the support plate 82, the guide rod 83, the stay cord 84, the third handwheel 85, the second handwheel 86, the worm wheel 87, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com