Automatic mold opening and closing mechanism for rubber coating and spraying of high-voltage electrified overhead bare conductor robot

A technology of automatic opening and closing and mold mechanism, applied in the field of power cables, can solve the problem of unsuitable opening and closing of bare wires, and achieve the effect of eliminating the need for climbing installation clamping devices and glue injection devices, and the effect of good encapsulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below.

[0024] The reference signs in the accompanying drawings of the specification include:

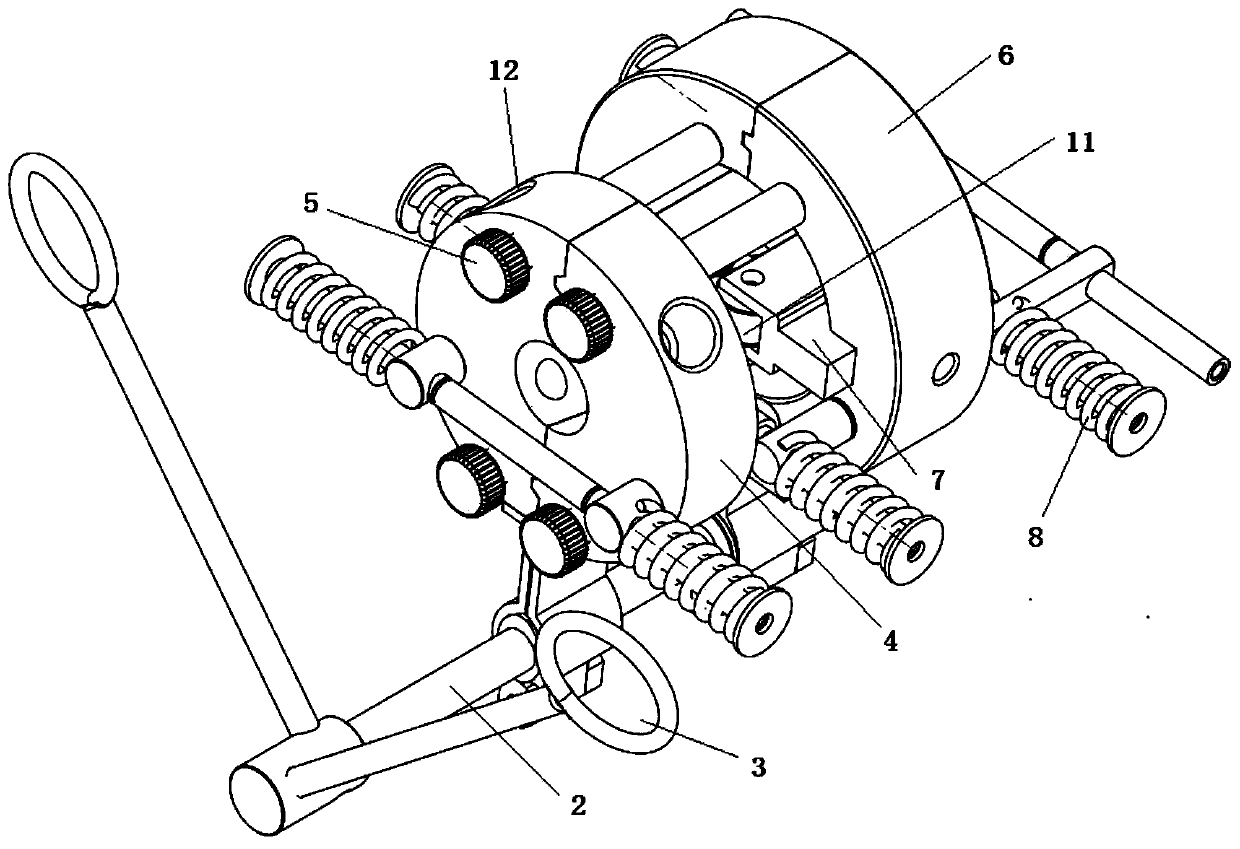

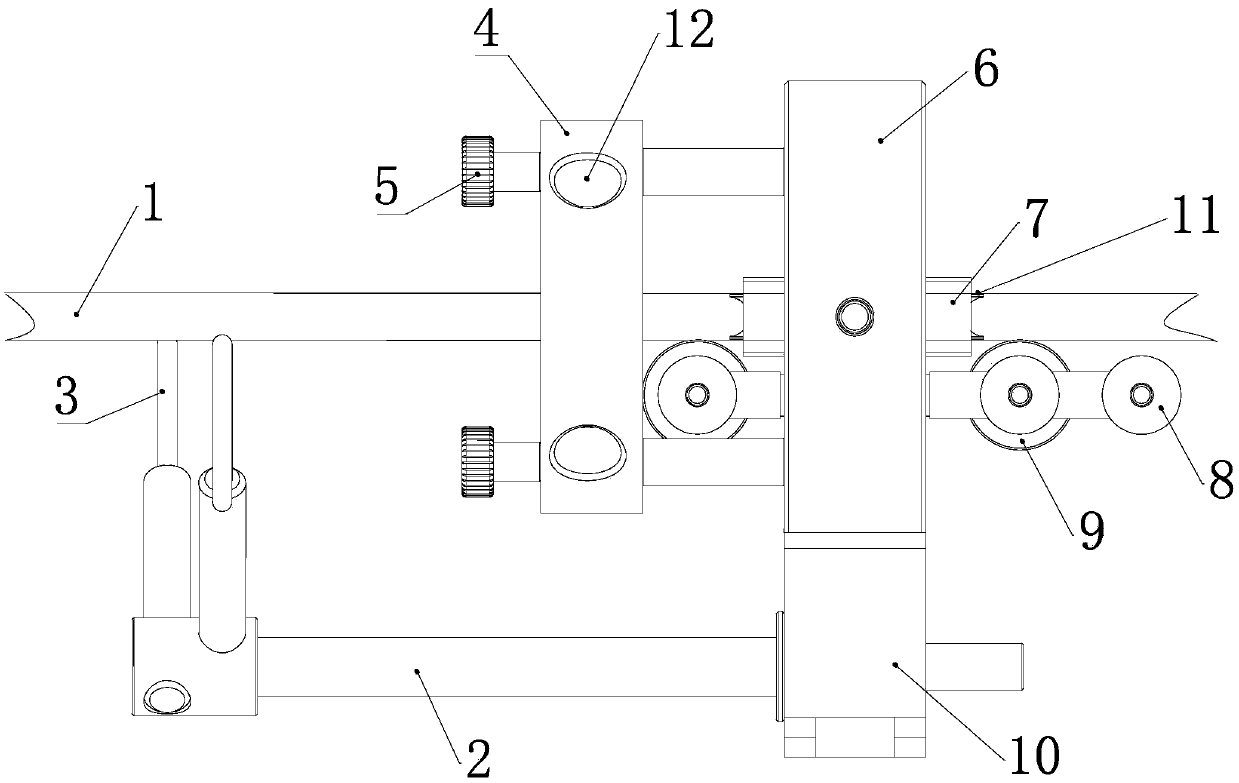

[0025] Bare wire 1, connecting rod 2, collar 3, injection molding pressure ring 4, fastener 5, clamping arm 6, clamping block 7, compression spring 8, roller 9, fixed seat 10, clamping wheel 11, injection hole 12.

[0026] Such as Figure 1~2 The shown high-voltage live overhead bare wire robot coating spraying automatic mold opening and closing mechanism includes a fixed seat 10 whose lower part is hinged and an upper part with an open shape, arc-shaped clamping arms 6 fixedly installed on both sides of the fixed seat 10, and clamping arms 6 connected with the clamping The arms 6 are respectively fixedly connected to the arc-shaped injection molding pressure ring 4, and the clamping arm 6 is fixedly connected to the upper part of the corresponding injection molding pressure ring 4 through the faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com