Preparation method of personal care electronic product rubber-coated handle

A technology of electronic products and encapsulation, which is applied in the direction of coating, etc., can solve the problems of destroying the bonding force, difficulty in finding glue, and decreasing bonding force of engineering plastics, so as to improve the strength and bonding fastness, facilitate continuous production, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

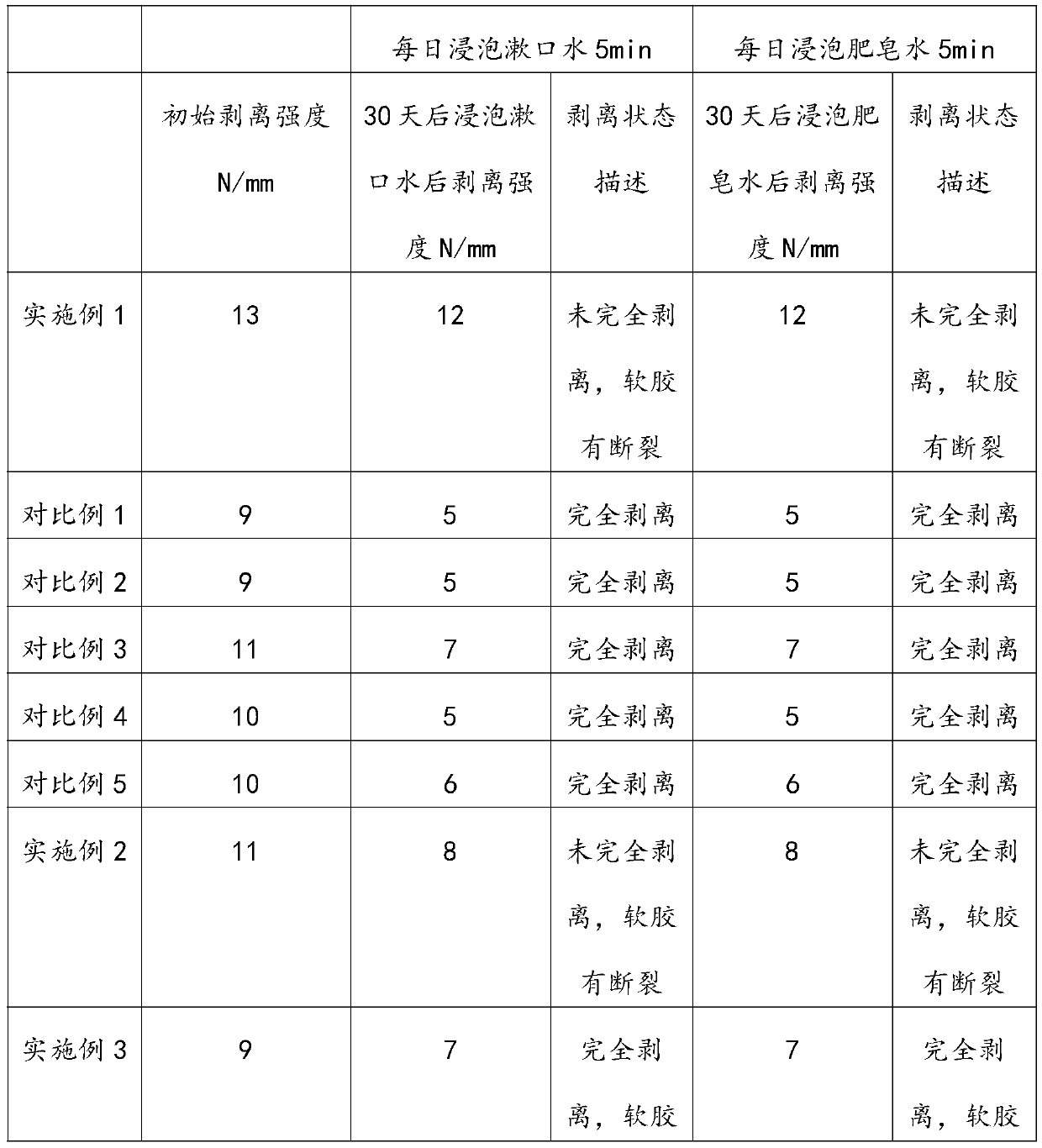

Embodiment 1

[0023] A method for preparing a plastic-coated handle of an electronic product for personal care, the steps are as follows:

[0024] (1) Preparation of hard modified TPU

[0025] Take 85 parts of MIRATHANE E175D with a hardness of 75D, 5 parts of maleic anhydride grafted ABS, 3 parts of SEBS6151 and 7 parts of mineral oil, mix them evenly, and put them into a twin-screw extruder for reaction. Control the melting temperature of the twin-screw extruder to 240°C , the screw speed is 300r / min, and the residence time is 2min; after underwater pelletizing, the water temperature is controlled at 40°C, and dried at 60°C for 2h;

[0026] (2) Preparation of soft modified TPU

[0027] Take 85 parts of MIRATHANE E180 with a hardness of 80A, 10 parts of maleic anhydride grafted SEBS, 10 parts of SEBS6151 and 15 parts of mineral oil, mix them evenly, enter the twin-screw extruder for reaction, and control the melting temperature of the twin-screw extruder to 240°C , the screw speed is 300...

Embodiment 2

[0060] A method for preparing a plastic-coated handle of an electronic product for personal care, the steps are as follows:

[0061] (1) Preparation of hard modified TPU

[0062] Take 90 parts of MIRATHANE E165D with a hardness of 65D, 5 parts of maleic anhydride grafted ABS, 5 parts of SEBS9551 and 5 parts of mineral oil, mix them evenly, enter the twin-screw extruder for reaction, and control the melting temperature of the twin-screw extruder to 200°C , the screw speed is 200r / min, and the residence time is 2min; after underwater pelletizing, the water temperature is controlled at 50°C, and dried at 70°C for 1h;

[0063] (2) Preparation of soft modified TPU

[0064] Take 95 parts of MIRATHANE E265 with a hardness of 65A, 5 parts of maleic anhydride grafted SEBS, 6 parts of SEBS9551 and 5 parts of mineral oil, mix them evenly, and put them into a twin-screw extruder for reaction. Control the melting temperature of the twin-screw extruder to 180°C , the screw speed is 210r / m...

Embodiment 3

[0068] A method for preparing a plastic-coated handle of an electronic product for personal care, the steps are as follows:

[0069] (1) Preparation of hard modified TPU

[0070] Take 85 parts of MIRATHANE M75D with a hardness of 75D, 5 parts of maleic anhydride grafted ABS, 3 parts of SEBS6154 and 7 parts of mineral oil, mix them evenly, enter the twin-screw extruder for reaction, and control the melting temperature of the twin-screw extruder to 250°C , the screw speed is 350r / min, and the residence time is 1min; after underwater pelletizing, the water temperature is controlled at 60°C, and dried at 80°C for 0.5h;

[0071] (2) Preparation of soft modified TPU

[0072] Take 85 parts of MIRATHANE M80 with a hardness of 80A, 10 parts of maleic anhydride grafted SEBS, 10 parts of SEBS6154 and 15 parts of mineral oil, mix them evenly, enter the twin-screw extruder for reaction, and control the melting temperature of the twin-screw extruder to 240°C , the screw speed is 320r / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com