TPE nylon rubber-coated particle material with high fluidity and high binding power and preparation method thereof

A technology with high cohesion and high fluidity, which is applied in the field of TPE nylon coated pellets and its preparation, can solve the problems of poor coating effect, difficult coating, insufficient fluidity and cohesive force, etc., and achieve good Encapsulation effect, stable viscosity, and effect of improving adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

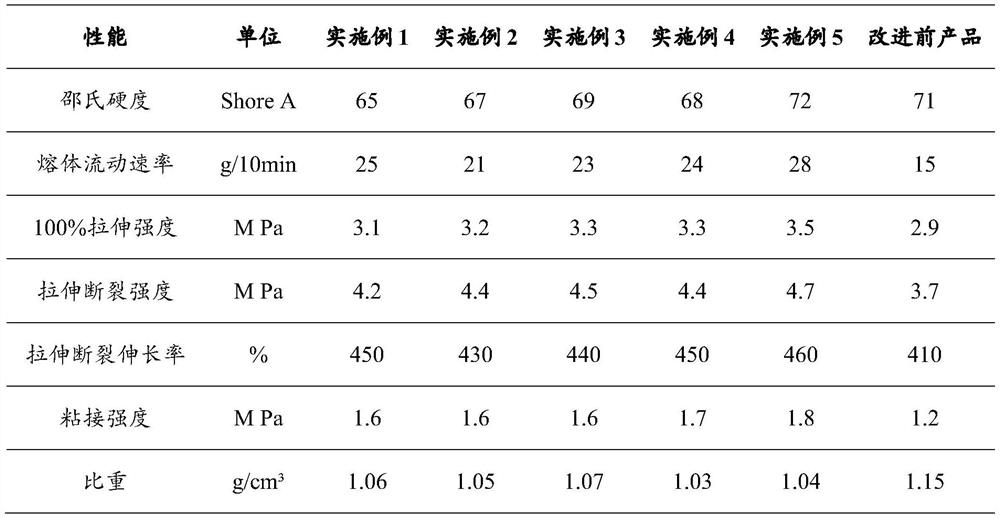

Examples

Embodiment 1

[0039] This embodiment is to prepare a kind of TPE nylon encapsulated pellet with high fluidity and high cohesive force, comprising the following steps:

[0040] S1: Preparation of raw materials: Weigh 10 parts of styrene elastomer, 20 parts of white oil, 5 parts of maleic anhydride grafted polystyrene elastomer, 5 parts of maleic anhydride grafted polyethylene, and 5 parts of maleic anhydride grafted polyethylene by weight. 10 parts POE, 10 parts polypropylene, 10 parts calcium carbonate, spare;

[0041] S2: Blending of raw materials: Add the raw materials of each component prepared in step S1 into the heating type high-speed melt blending machine according to the predetermined order and speed for blending to form a TPE nylon encapsulation premix. The specific steps are:

[0042] S2-1: Start the heating type high-speed melt blender to raise the temperature to 35°C, add styrene elastomer, maleic anhydride grafted polystyrene elastomer and white oil, control the stirring speed ...

Embodiment 2

[0049] Example 2: This example also prepares a high fluidity and high cohesion TPE nylon-encapsulated granule, and its preparation method is consistent with Example 1. Calculated as: 12 parts of styrene elastomer, 25 parts of white oil, 6 parts of maleic anhydride grafted polystyrene elastomer, 6 parts of maleic anhydride grafted polyethylene, 12 parts of maleic anhydride grafted POE, 12 parts of polypropylene parts, 12 parts of calcium carbonate.

Embodiment 3

[0050] Example 3: The TPE nylon coated pellets with high fluidity and high cohesion prepared in this example, its preparation method is consistent with Example 1, and its components are calculated in parts by mass: 15 parts of styrene elastomer , 30 parts of white oil, 8 parts of maleic anhydride grafted polystyrene elastomer, 8 parts of maleic anhydride grafted polyethylene, 15 parts of maleic anhydride grafted POE, 15 parts of polypropylene, and 15 parts of calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com