Automatic adhesive feeding device for tabs

An automatic and glue-feeding technology, applied in electrical components, circuits, battery pack components, etc., can solve problems such as low production efficiency, poor consistency of pole ears, asynchronous progress, etc., to improve production efficiency, reduce defect rates, and improve performance. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

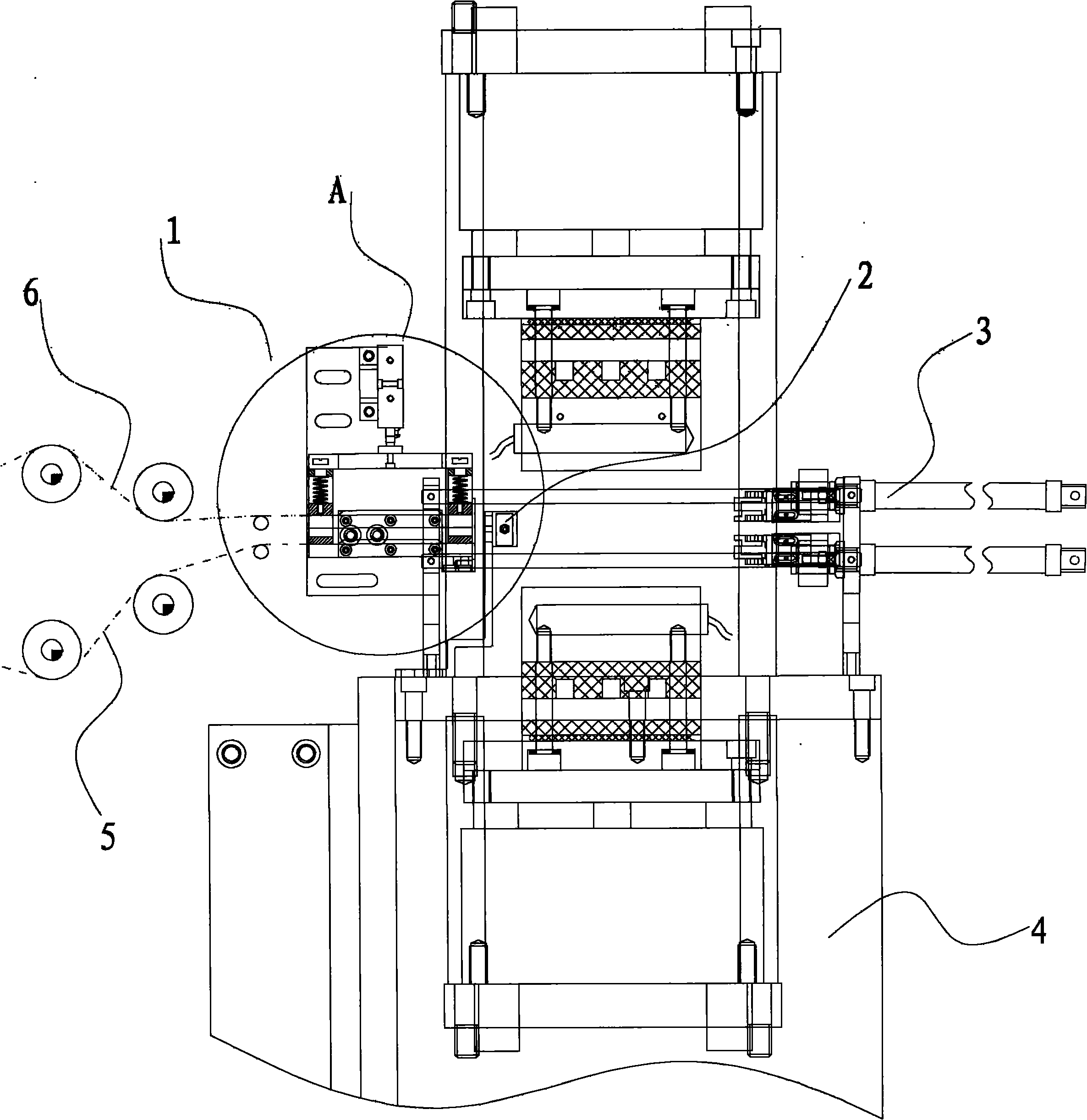

[0016] like figure 1 As shown, the tab automatic glue feeding device mainly includes a glue strip mechanism 1, a glue strip cutting mechanism 2 and a glue strip mechanism 3; the glue strip mechanism 1 is fastened on the machine panel (not shown in the figure) , The rubber strip cutting mechanism 2 and the rubber strip clamping mechanism 3 are fixed on the machine base 4 .

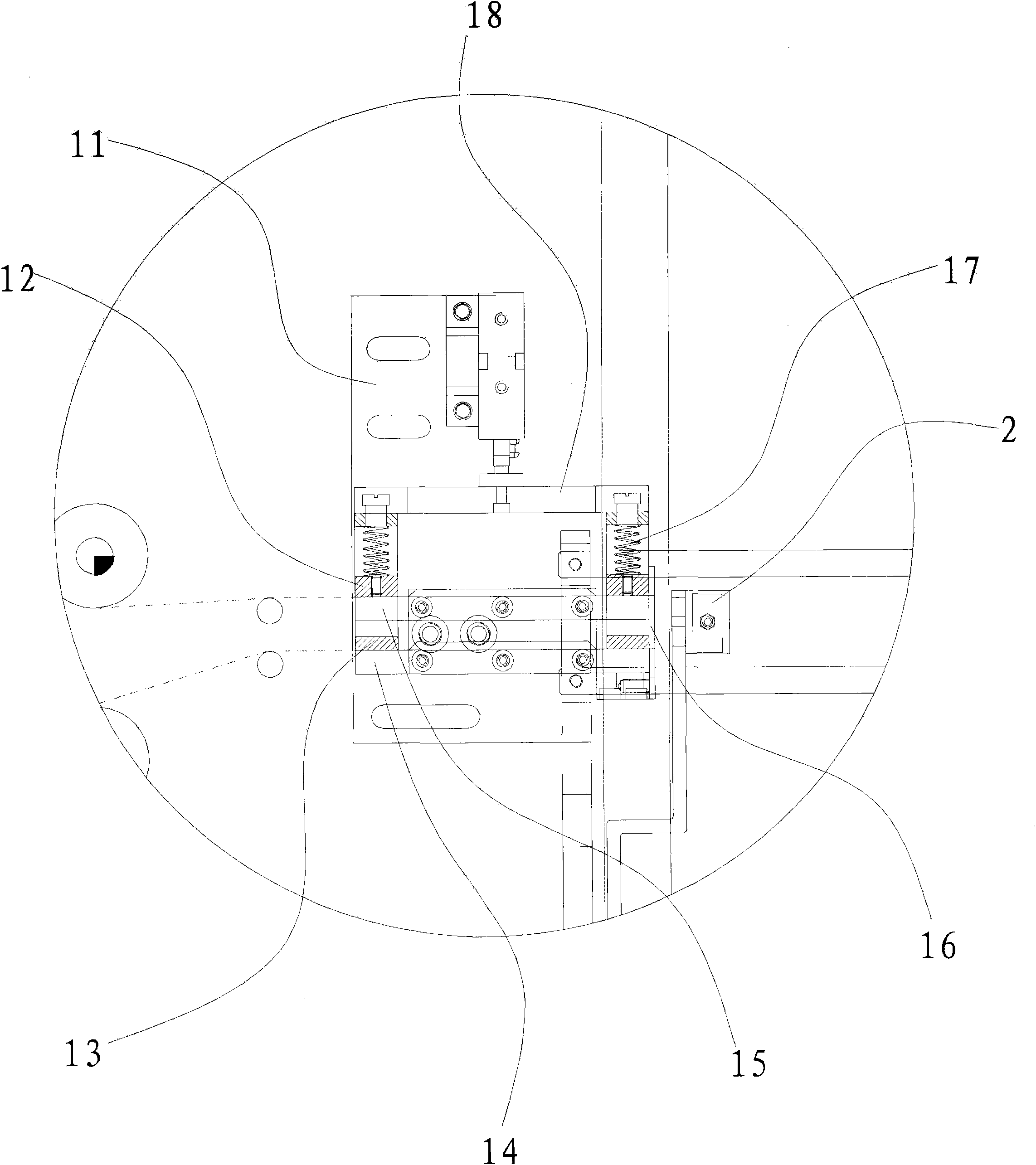

[0017] like image 3 As shown, the rubber strip mechanism 1 is mainly composed of a biaxial cylinder 11, a compression spring 17, an upper movable pressing block 12, a lower movable pressing block 13, an upper fixed pressing plate 15, a lower fixed pressing plate 14, a guide plate 16 and a connecting plate 18; the biaxial cylinder 11 is connected to the upper end of the compression spring 17 through the connecting plate 18, and the lower end of the compression spring 17 is connected to the upper and lower movable pressure blocks (12, 13); the upper fixed pressure plate 15 is correspondingly arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com