Adhesive tape rotating disc winding machine of transformer adhesive tape packaging machine

A technology of laminating machine and transformer, which is applied in inductance/transformer/magnet manufacturing, transportation and packaging, electrical components, etc. The effect of convenient and quick production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

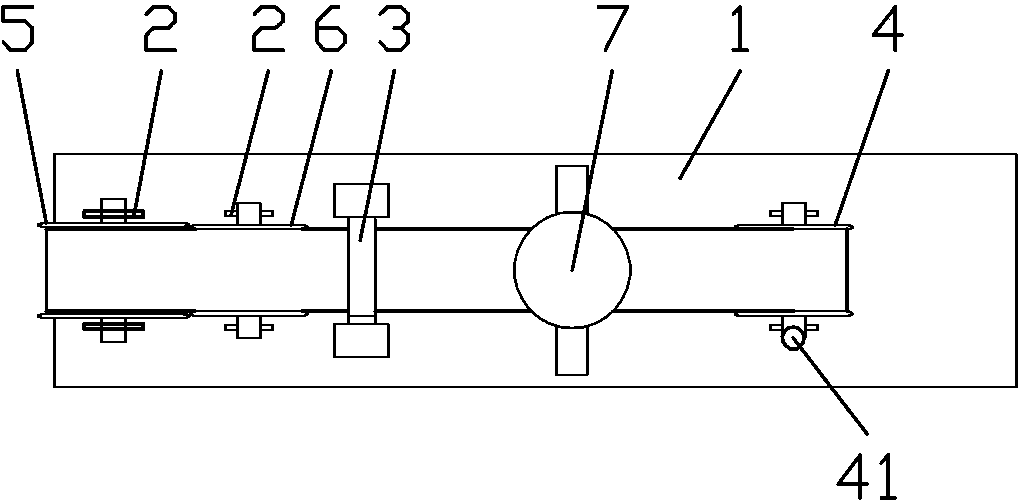

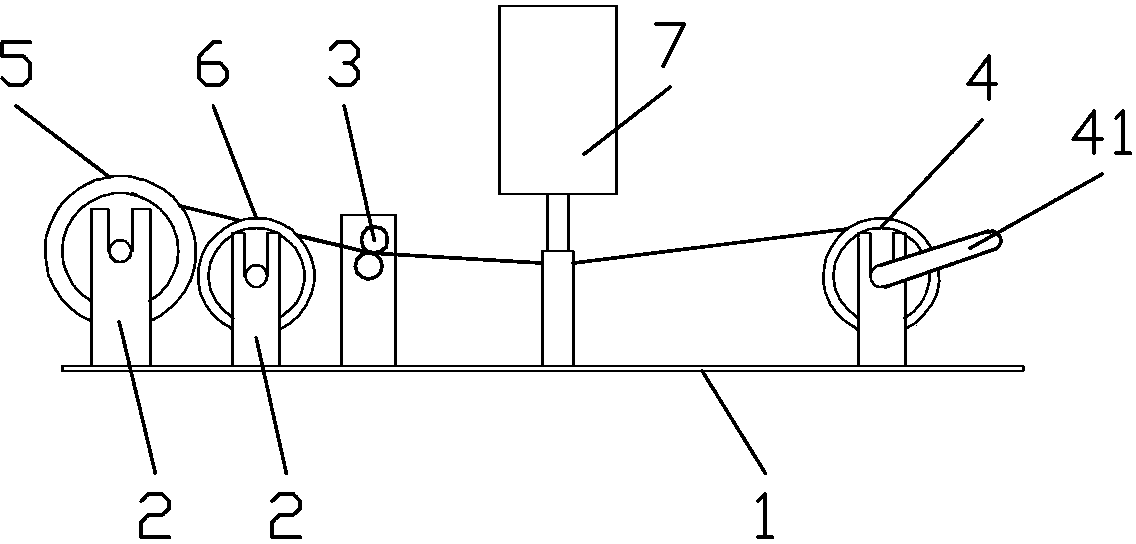

[0013] like figure 1 , 2 As shown, the present invention provides a tape turntable winding machine for a transformer encapsulation machine, including a base 1, wherein, along the length direction of the base 1, a support 2, a pressure roller 3, a receiving tray 4, and a support 2 are arranged in sequence. A tape turntable is provided. The tape turntable includes an outer tape turntable 5 and an inner tape turntable 6. The tape width of the outer tape turntable 5 is larger than that of the inner tape turntable 6. The tapes of the tape turntable pass through the pressure roller 3 and extend to the receiving tray 4 , the end of the combined adhesive tape is connected to the receiving tray 4 , and a cutting device 7 is provided between the receiving tray 4 and the pressure roller 3 . In addition, considering the efficiency of tape winding, the receiving tray 7 is connected with a driving device; considering the convenience of controlling the winding length of the tape, the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com