Full coated encapsulate formed article and its forming method

A technology of molding and surface coating, applied in the direction of coating, etc., can solve the problems of difficult control of process factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

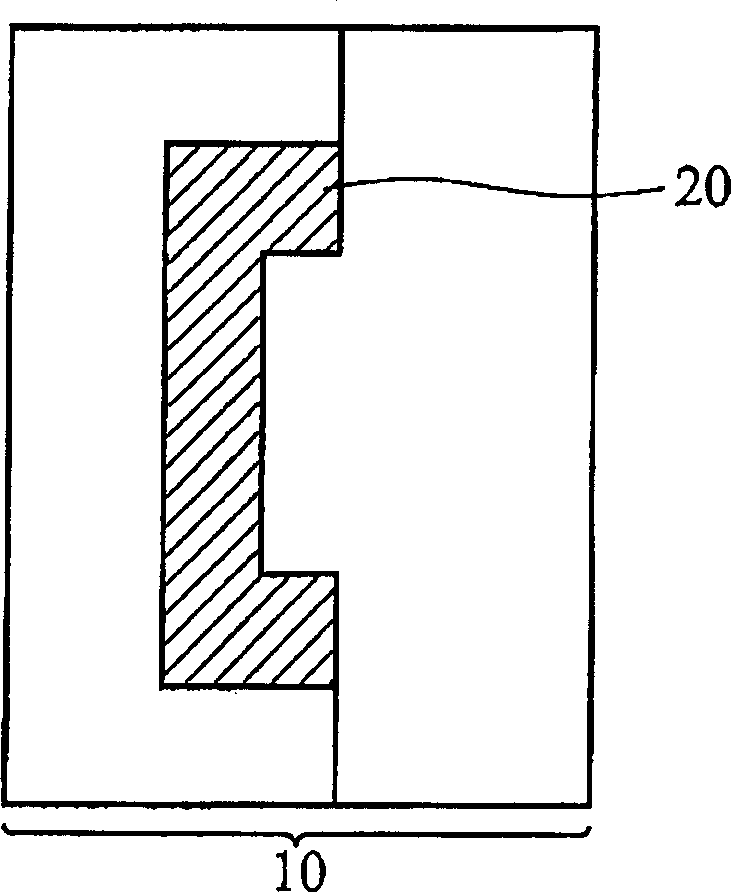

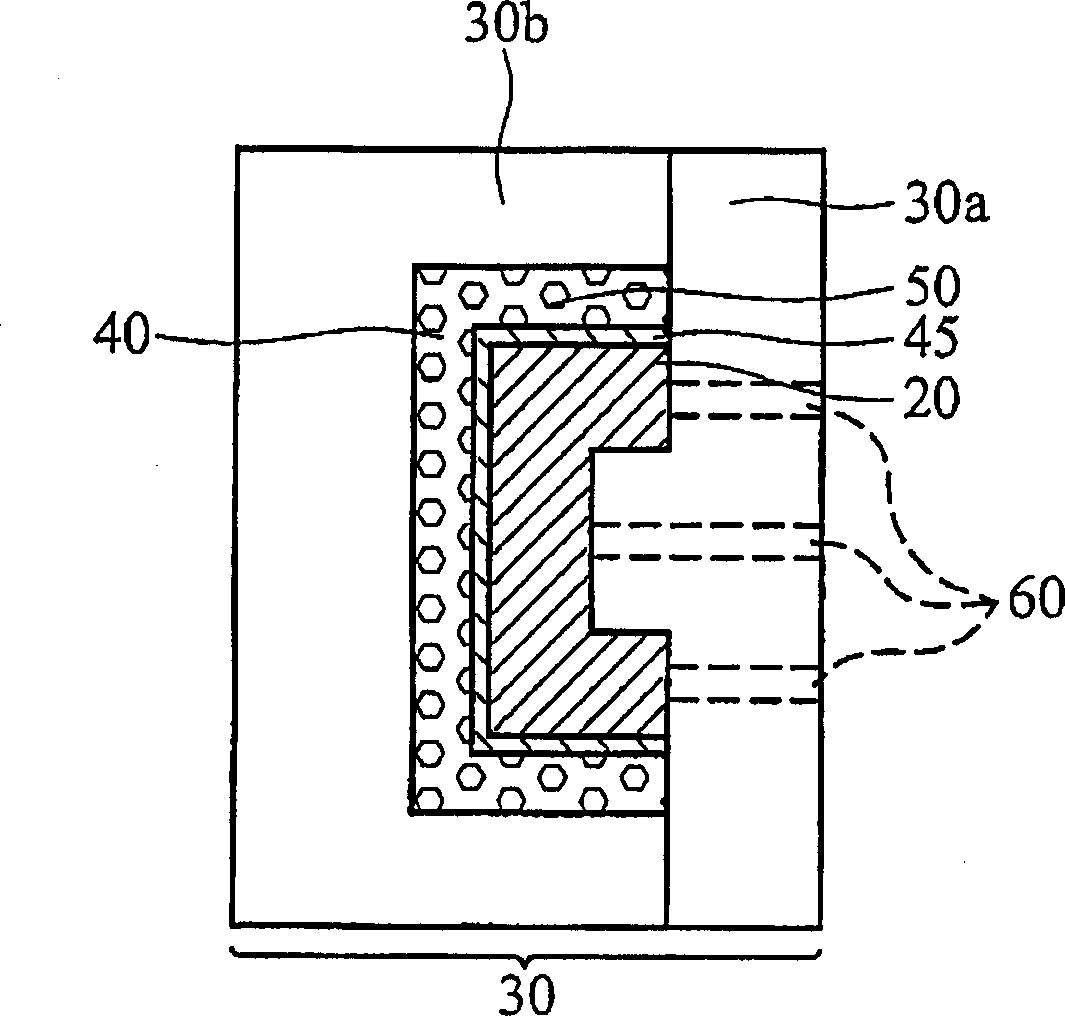

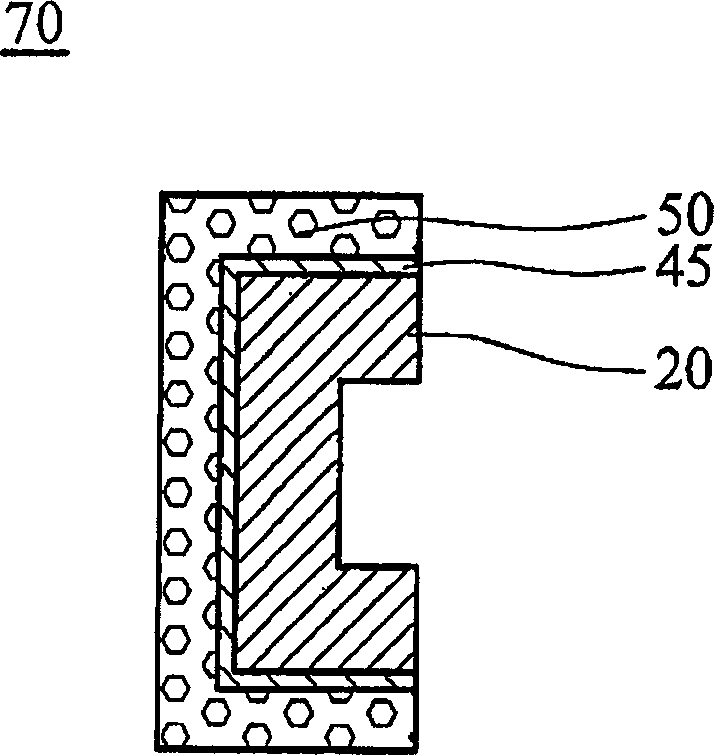

[0029] Please refer to figure 1 , figure 1 It is a schematic diagram showing the molding steps of the polymer material of the present invention, which uses a material mold 10 to form a polymer material 20, wherein the material 20 is preferably selected from a material with a high heat distortion temperature, such as polycarbonate (polycarbonate, PC) Or ABS (acrylonitrile butadienestyrene); in addition, it is more preferable if it is a combination of the aforementioned substances. In the present invention, in order to counteract the deformation problems such as shrinkage stress produced when the lagging is covered with thermoplastic elastomer as described later, the material is preferably a composite material of polycarbonate (PC) plus ABS GE C2800 , and its physical properties are shown in Table 1. In addition, the material 20 can be added with other additives such as fillers, reinforcing agents, processing aids, flow promoters or pigments according to actual needs. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com