Impact test machine with steel ball self-reset function

A test test, self-homing technology, applied in the direction of impact test, machine/structural component test, measurement device, etc., can solve the problems of low efficiency, increased labor intensity, long test process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

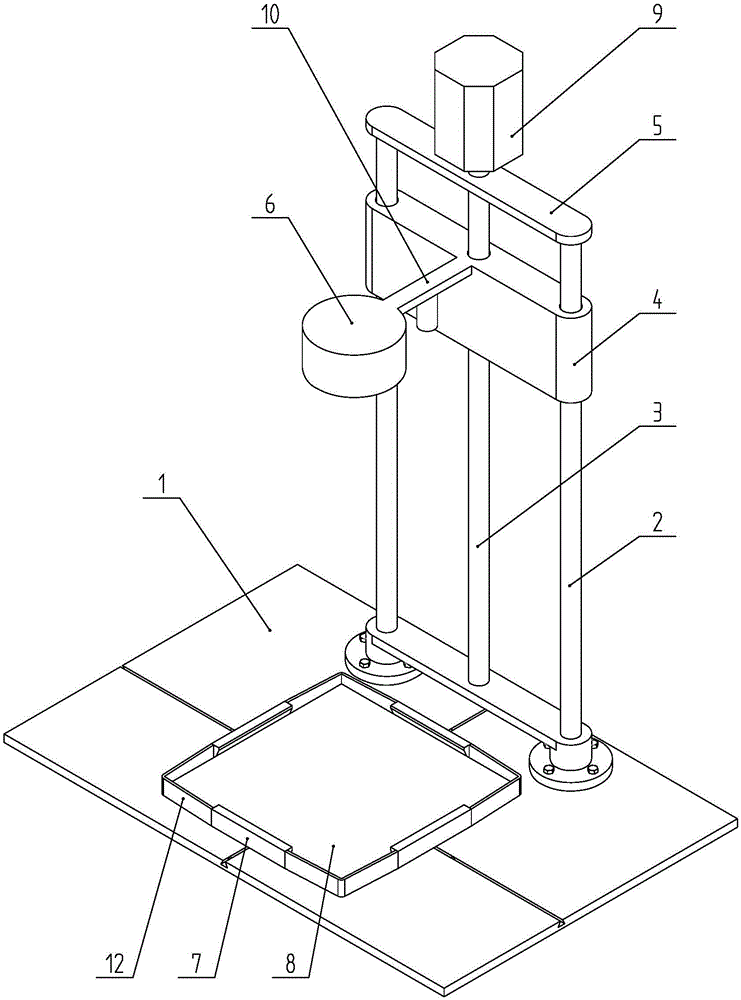

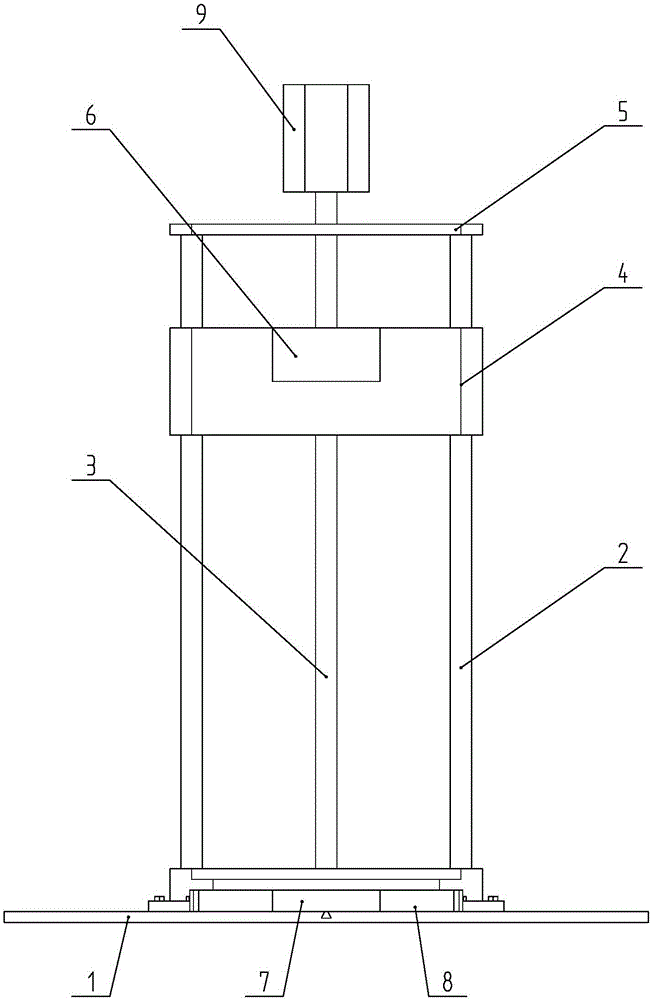

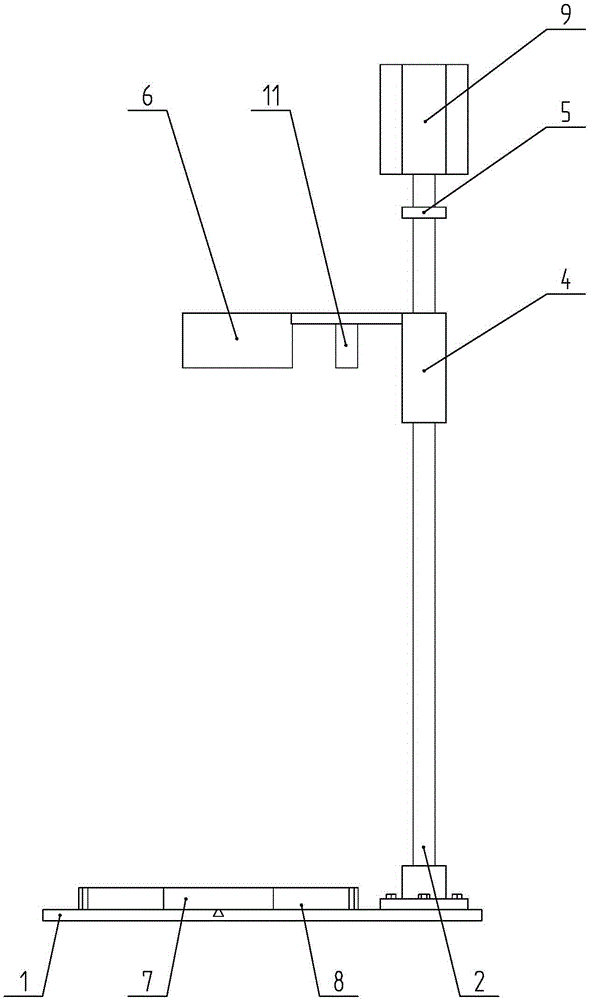

[0022] like Figures 1 to 4 As shown, a steel ball self-returning impact resistance testing machine includes a test stand 1 and a test stand installed on the test stand 1. The test frame includes a lead screw 3, two guide columns 2, a slide table 4, a beam 5, and a motor 9. Lead screw and guide post 2 are all vertically installed on the test bench 1, and lead screw 3 is positioned at the center of two guide posts 2, and lead screw 3 can rotate, and guide post 2 is fixed. A crossbeam 5 for fixing the motor 9 is installed on the tops of the two guide posts 2 , and the upper end of the leading screw 3 is connected with the main shaft of the motor 9 . The slide table 4 cooperates with the lead screw 3 through the screw pair, and cooperates with the guide post 2 through the moving pair. A horizontal support 10 is installed on the slide table 4, and a downward magnetic base 6 and a laser range finder 11 are installed on the support 10; the bottom end surface of the magnetic base 6...

Embodiment 2

[0026] In the present invention, the positioning block 7 includes a vertical portion and a horizontal portion connected to the vertical upper end, and the side for positioning on the positioning block 7 is the inner side of the aforementioned two.

[0027] Working process and principle of the present invention

[0028] Place the object under test on the test table, and place the positioning block in contact with each edge of the object under test, pull the elastic band to make it clamp the edge of the main object under test and then achieve pre-positioning under the action of tightening force, and then Secure by tightening bolts. Determine the test height H and select the steel ball according to the test requirements, then start the motor 9 to control the sliding table 4 to descend until the bottom surface of the magnetic base 6 is in contact with the steel ball, and then pause. At this time the height is H 1 (ie steel ball diameter D). Then start motor 9 to control slide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com