Light cast-in-place high-strength formwork non-dismantling wall and construction method thereof

A formwork and wall technology, which is applied in the field of light-weight cast-in-place high-strength formwork without demolition and its construction field, can solve the problems of prolonging the construction period and inconvenient wall construction process, and achieve weight reduction, shortening construction period, and installation process. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-3 The application is described in further detail.

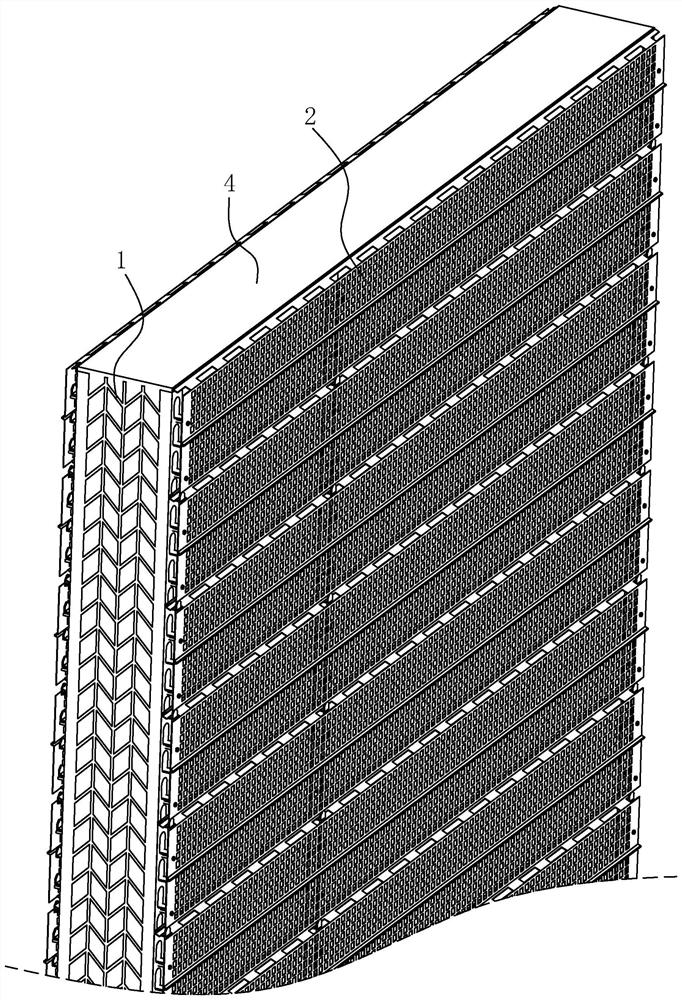

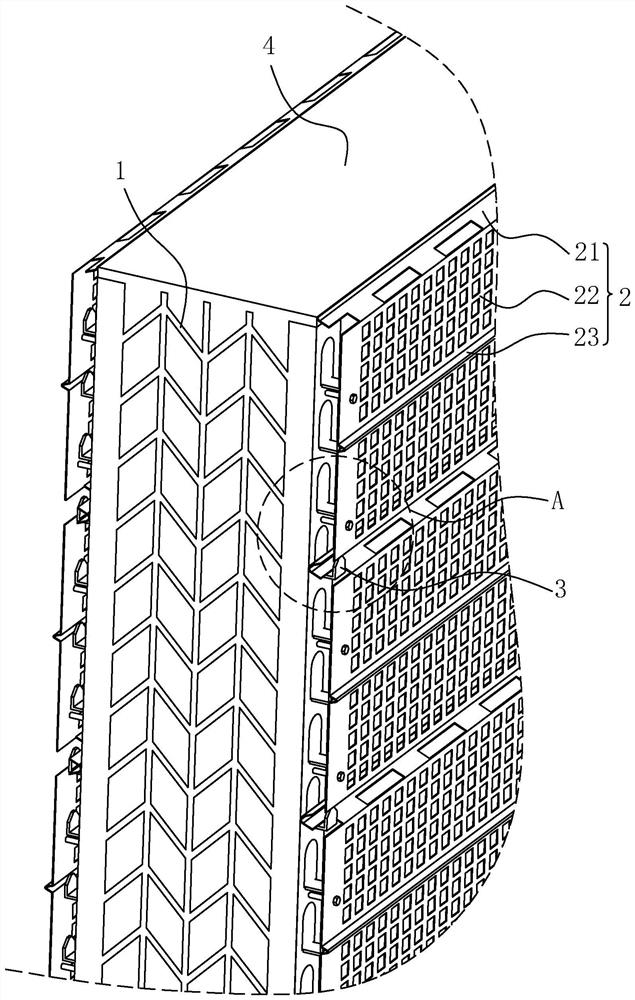

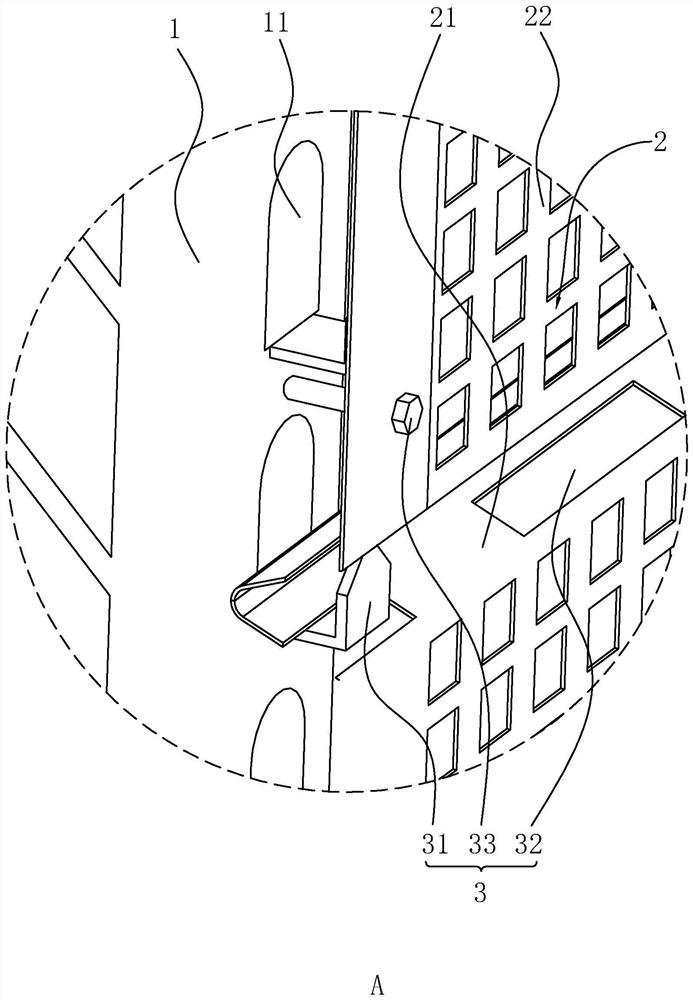

[0041] The embodiment of the present application discloses a light-weight cast-in-place high-strength formwork without demolition of the wall. refer to figure 1 A light-weight cast-in-place high-strength formwork non-demolition wall includes several keels 1 arranged along the length direction of the wall, grid-like formwork 2 is arranged on both sides of the wall, and the formwork 2 on both sides of the wall is poured There are concrete bodies 4.

[0042] During construction, the keel 1 is first fixed to the ground and the roof, then the formwork 2 on both sides of the wall is fixed on the keel 1, and finally concrete is poured between the formwork 2 on both sides of the wall to form the concrete main body 4, so that Both the keel 1 and the formwork 2 are integrated with the concrete main body 4, which avoids supporting the formwork 2 before pouring concrete, and avoids dismantlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com