Body side buckles automatically-folding device and folding method thereof

A technology of a folding device and a side wall card is applied in the field of automobile assembly, which can solve the problems of long time, unguaranteed pre-bending consistency and effect, and high strength, and achieves the advantages of improving work efficiency, saving manpower and ensuring bending effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

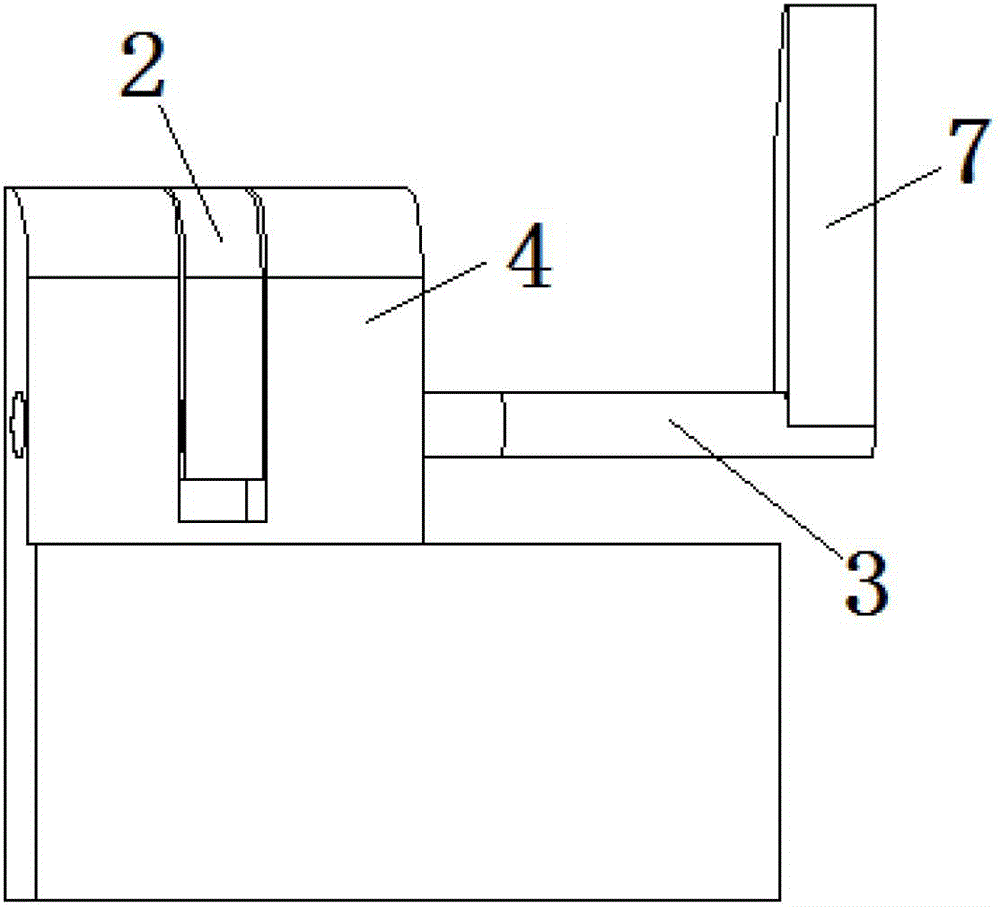

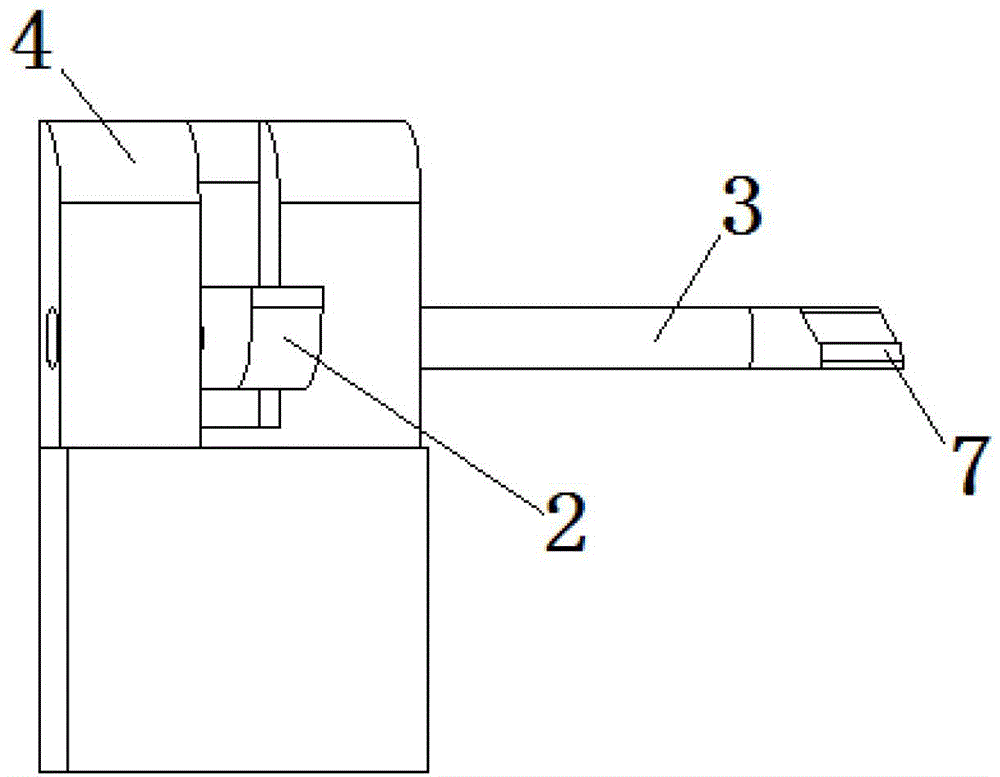

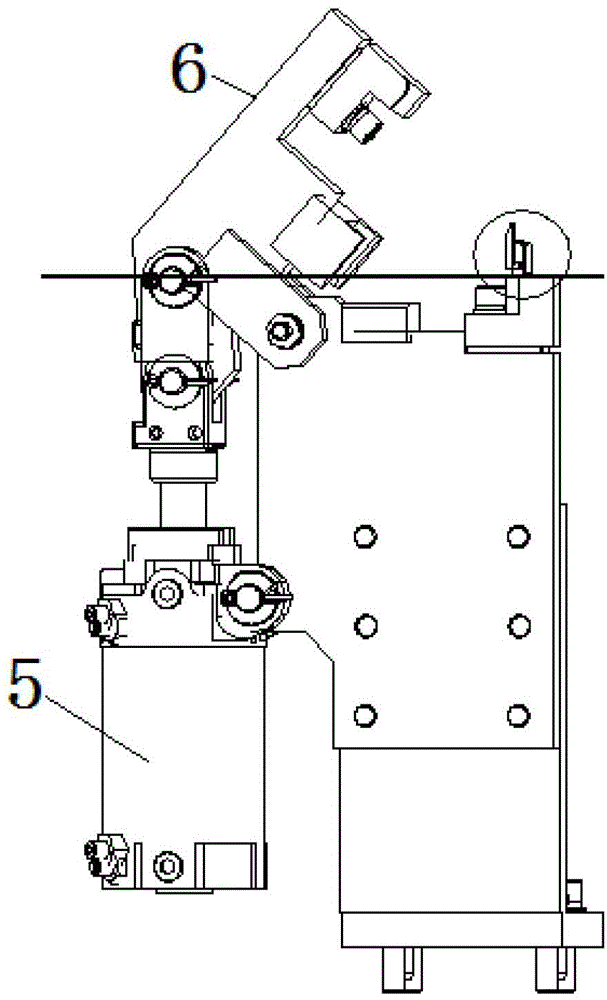

[0028] Such as figure 1 and figure 2 As shown, the automatic hemming device for side buckle of the vehicle body includes a guide block 4; The rotating shaft 3 of the tight block 2, one end of the rotating shaft 3 stretches out the guide block 4, driven by the rotating shaft 3, the pressing block 2 can relatively rotate along the guide surface of the guide block 4.

[0029] The pressing surface of the pressing block 2 is arranged on one side of the guiding surface of the guiding block 4 , and the pressing surface of the pressing block 2 is not higher than the guiding surface of the guiding block 4 .

[0030] One end of the rotating shaft 3 protruding from the guide block 4 is provided with a connecting block 7, and the connecting block 7 can drive the rotating shaft 3 and then drive the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com