Inner tooth pre-positioning device and inner tooth grinding method

A technology for pre-positioning devices and internal teeth, which is applied in the direction of gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of increasing the tooth top circle grinding process, low efficiency, uncertainty of alignment state, waste, etc., and achieves improved The effect of processing quality, avoiding uncertainty, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

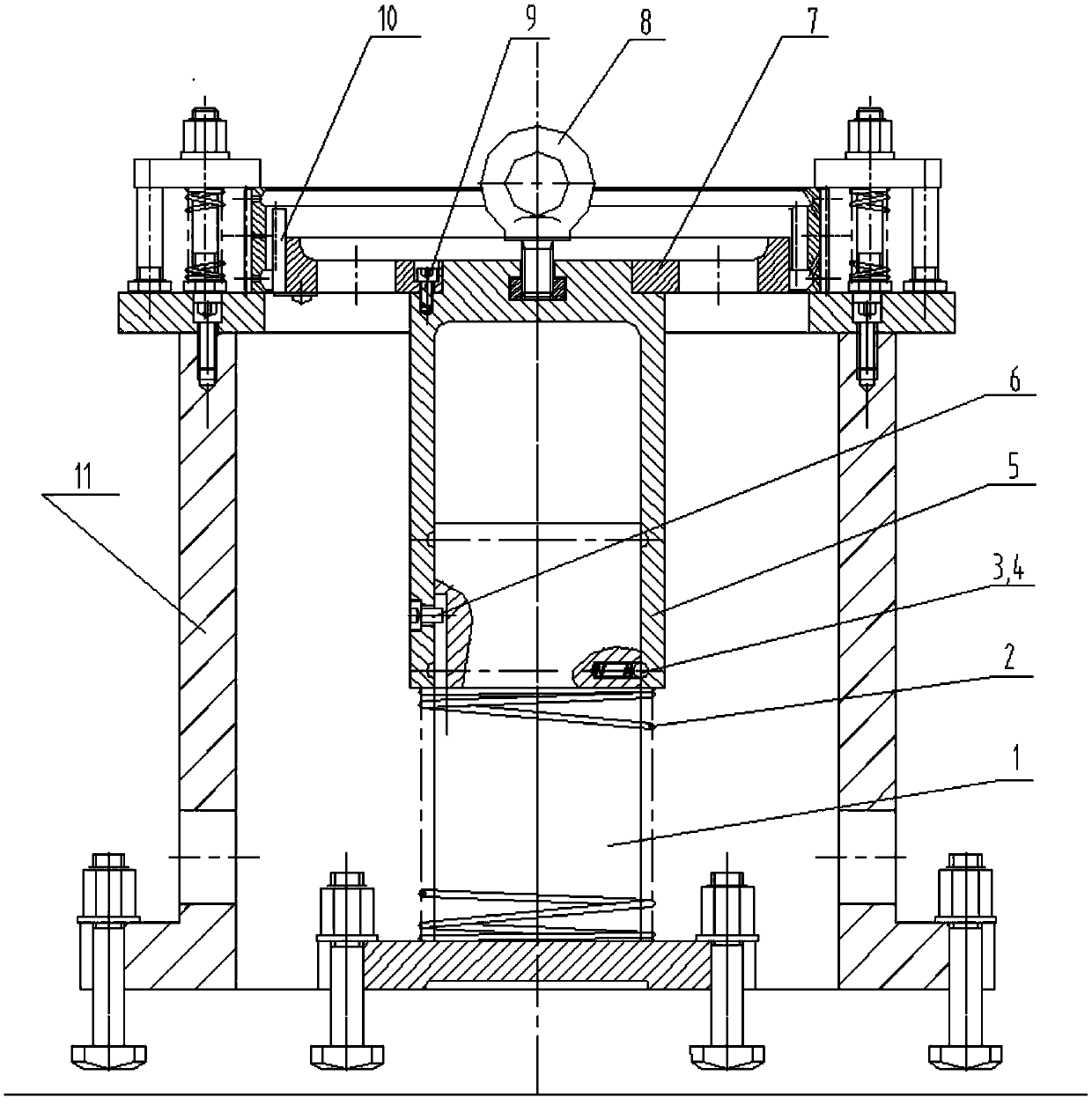

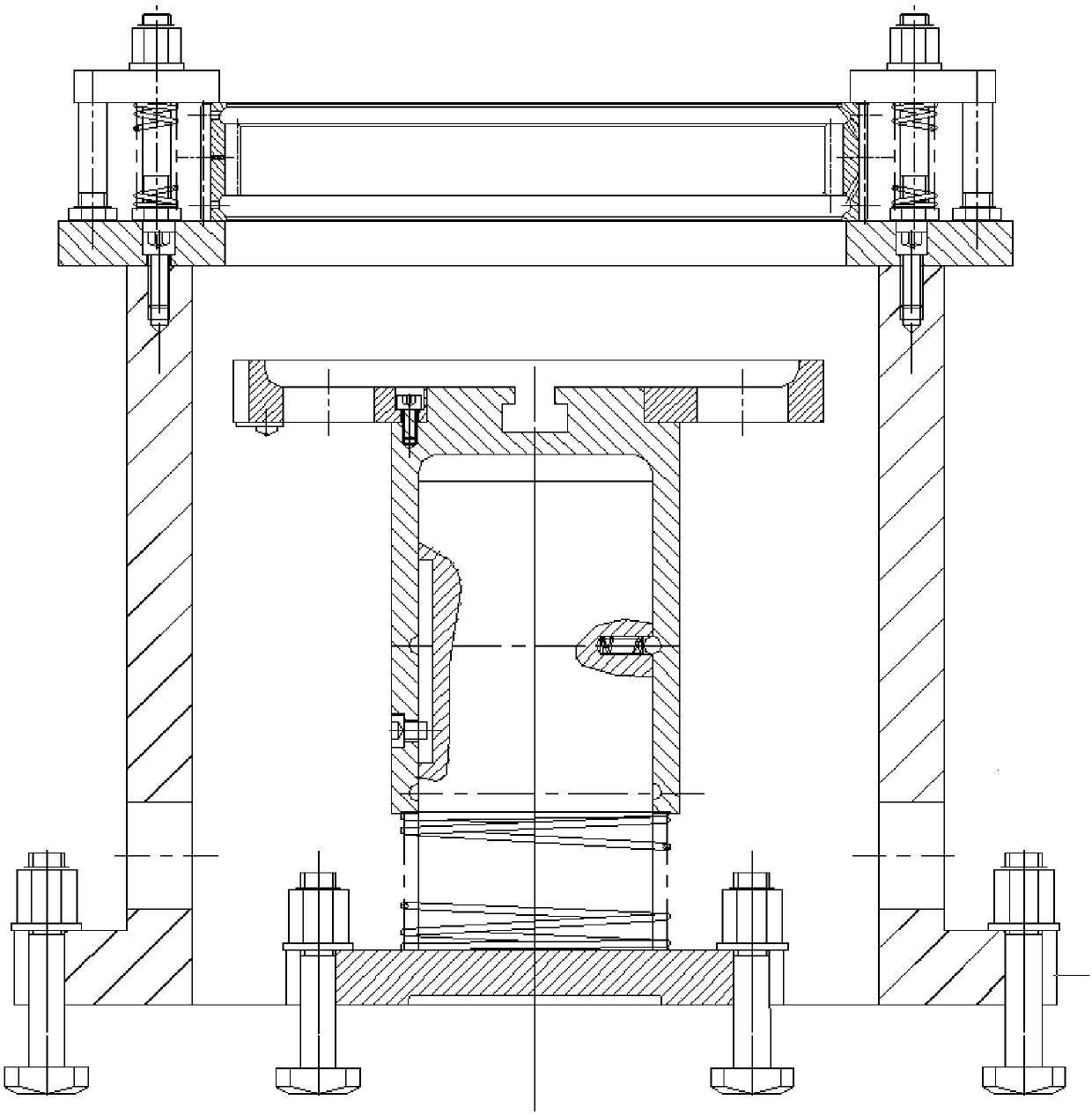

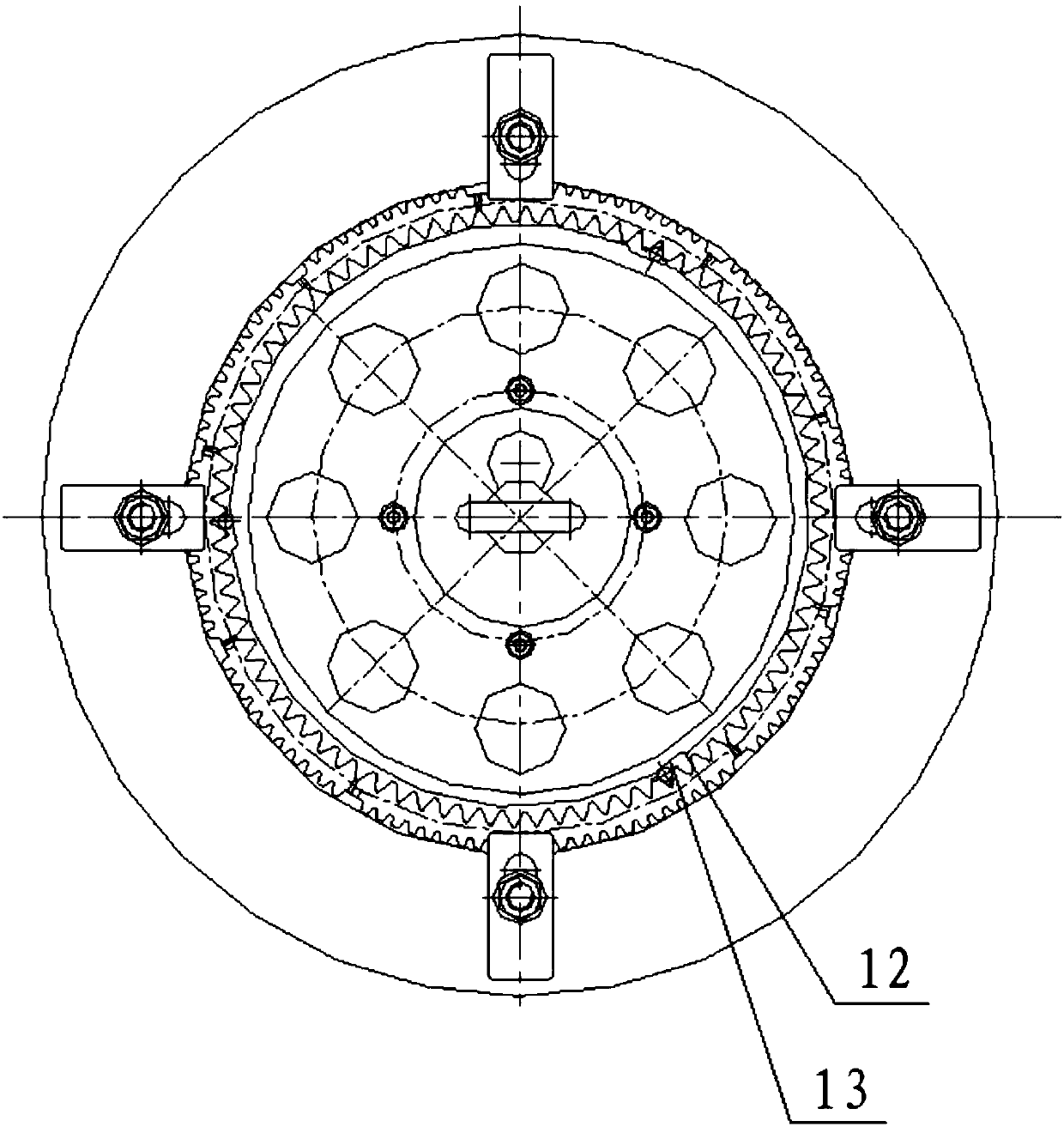

[0025] Such as figure 1 As shown, the present invention provides a pre-positioning device for internal teeth, which mainly includes a positioning support 1, a vertical spring 2, a horizontal spring 3, a steel ball 4, a guide sleeve 5, a limit screw 6, a positioning plate 7, a detachable Handle 8, screw 9, rolling bar 10; Grinding bearing 11 is used in conjunction with positioning device.

[0026] The positioning disc 7 is fixed on the top of the guide sleeve 5 by screws 9;

[0027] Put the vertical spring 2 on the positioning support 1, put the horizontal spring 3 and the steel ball 4 into the holes corresponding to the positioning support 1 horizontally, and set the guide sleeve 5 on the positioning support 1, and its bottom end and the upper end of the spring Contact, the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com